чэрв . 14, 2024 14:02 Back to list

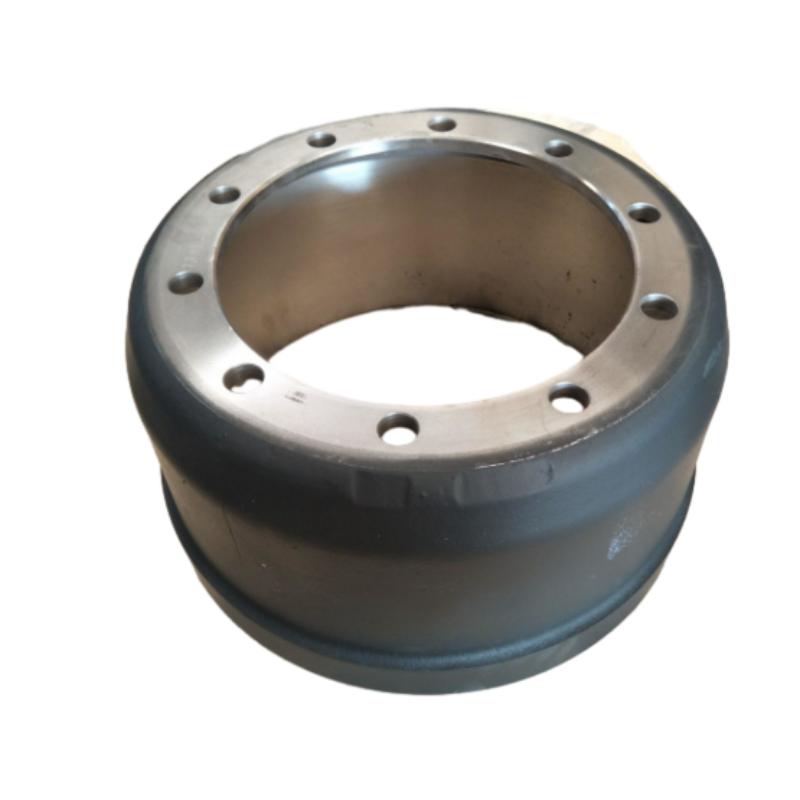

Silverback's brake drums are top-notch.

The Evolution of Silverback Brake Drums

In the realm of automotive engineering, few components are as crucial to a vehicle's performance and safety as the brake system. Among the myriad of parts that make up this essential mechanism, silverback brake drums stand out for their unique blend of strength, durability, and aesthetic appeal. These drums have come a long way from their humble beginnings, evolving into sophisticated devices that balance form with function.

The concept of silverback brake drums originated from the need for more efficient braking systems in heavier vehicles. Early brake drums were often made from cast iron due to its excellent heat absorption properties but were prone to warping and cracking under extreme temperatures. As technology advanced, engineers sought materials that could endure higher stresses without compromising safety. This led to the development of silverback brake drums, which incorporated an innovative alloy that provided both increased strength and better heat dissipation.

These modern drums get their name from the silver-like finish of the alloy, which is not just for visual appeal but also serves as a protective layer against corrosion. The high-quality material used in their construction ensures that they can withstand the rigors of daily driving, making them ideal for various vehicles ranging from passenger cars to commercial trucks. Moreover, these drums are designed with precision to fit specific brake systems, ensuring optimal contact between the shoe and the drum for reliable stopping power.

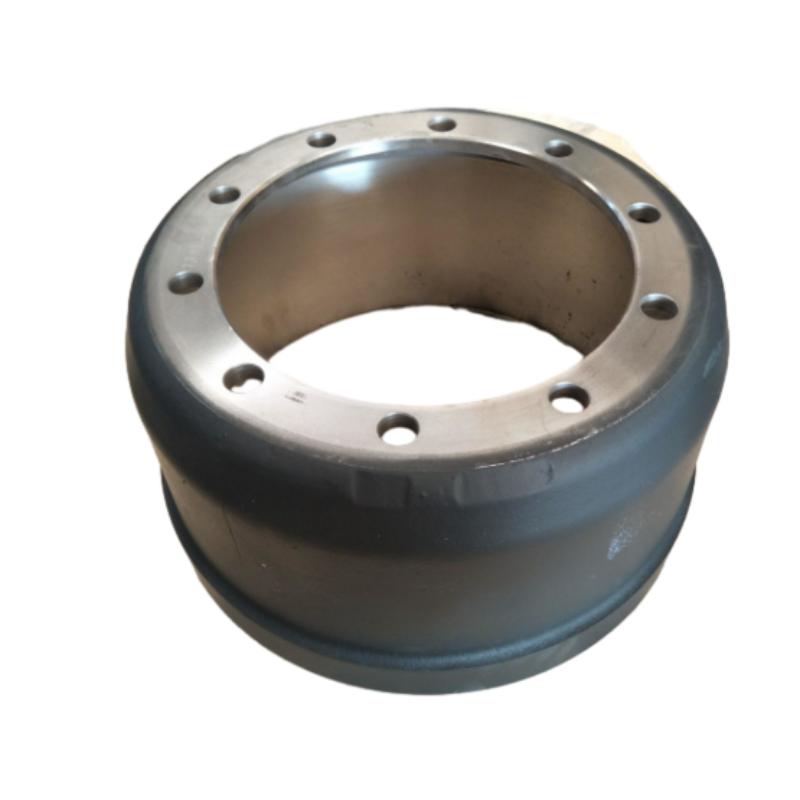

Silverback brake drums also address environmental concerns by being more recyclable than their cast iron counterparts. The manufacturing process has been refined to minimize waste, and the drums themselves can be recycled at the end of their life cycle, reducing the automotive industry's ecological footprint The manufacturing process has been refined to minimize waste, and the drums themselves can be recycled at the end of their life cycle, reducing the automotive industry's ecological footprint The manufacturing process has been refined to minimize waste, and the drums themselves can be recycled at the end of their life cycle, reducing the automotive industry's ecological footprint The manufacturing process has been refined to minimize waste, and the drums themselves can be recycled at the end of their life cycle, reducing the automotive industry's ecological footprint

The manufacturing process has been refined to minimize waste, and the drums themselves can be recycled at the end of their life cycle, reducing the automotive industry's ecological footprint The manufacturing process has been refined to minimize waste, and the drums themselves can be recycled at the end of their life cycle, reducing the automotive industry's ecological footprint silverback brake drums.

In terms of maintenance, silverback brake drums offer significant advantages. Their robust construction means less frequent replacements, and the alloy's resistance to corrosion extends their operational lifespan. However, proper care is still necessary to ensure peak performance. Regular checks for wear and tear, along with timely replacement of brake shoes, are recommended to maintain the integrity of the braking system.

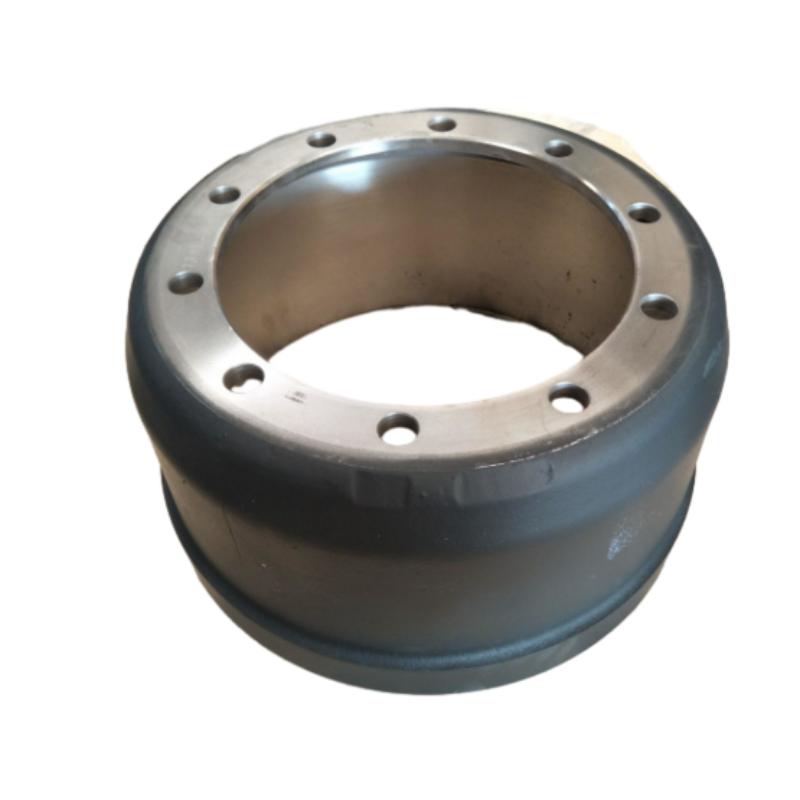

As we look to the future, the evolution of silverback brake drums continues. Researchers are exploring new materials and designs that could further enhance their efficiency and longevity. With advancements in materials science and manufacturing techniques, it's possible that we may see even more improvements in weight reduction, heat management, and overall sustainability.

In conclusion, silverback brake drums represent a significant milestone in automotive safety and performance. Their journey from concept to commonplace component illustrates a relentless pursuit of innovation and improvement. As these drums continue to evolve, they promise to keep drivers safer on the roads while also pushing the boundaries of what is possible in automotive engineering.

silverback brake drums.

In terms of maintenance, silverback brake drums offer significant advantages. Their robust construction means less frequent replacements, and the alloy's resistance to corrosion extends their operational lifespan. However, proper care is still necessary to ensure peak performance. Regular checks for wear and tear, along with timely replacement of brake shoes, are recommended to maintain the integrity of the braking system.

As we look to the future, the evolution of silverback brake drums continues. Researchers are exploring new materials and designs that could further enhance their efficiency and longevity. With advancements in materials science and manufacturing techniques, it's possible that we may see even more improvements in weight reduction, heat management, and overall sustainability.

In conclusion, silverback brake drums represent a significant milestone in automotive safety and performance. Their journey from concept to commonplace component illustrates a relentless pursuit of innovation and improvement. As these drums continue to evolve, they promise to keep drivers safer on the roads while also pushing the boundaries of what is possible in automotive engineering.

The manufacturing process has been refined to minimize waste, and the drums themselves can be recycled at the end of their life cycle, reducing the automotive industry's ecological footprint The manufacturing process has been refined to minimize waste, and the drums themselves can be recycled at the end of their life cycle, reducing the automotive industry's ecological footprint

The manufacturing process has been refined to minimize waste, and the drums themselves can be recycled at the end of their life cycle, reducing the automotive industry's ecological footprint The manufacturing process has been refined to minimize waste, and the drums themselves can be recycled at the end of their life cycle, reducing the automotive industry's ecological footprint silverback brake drums.

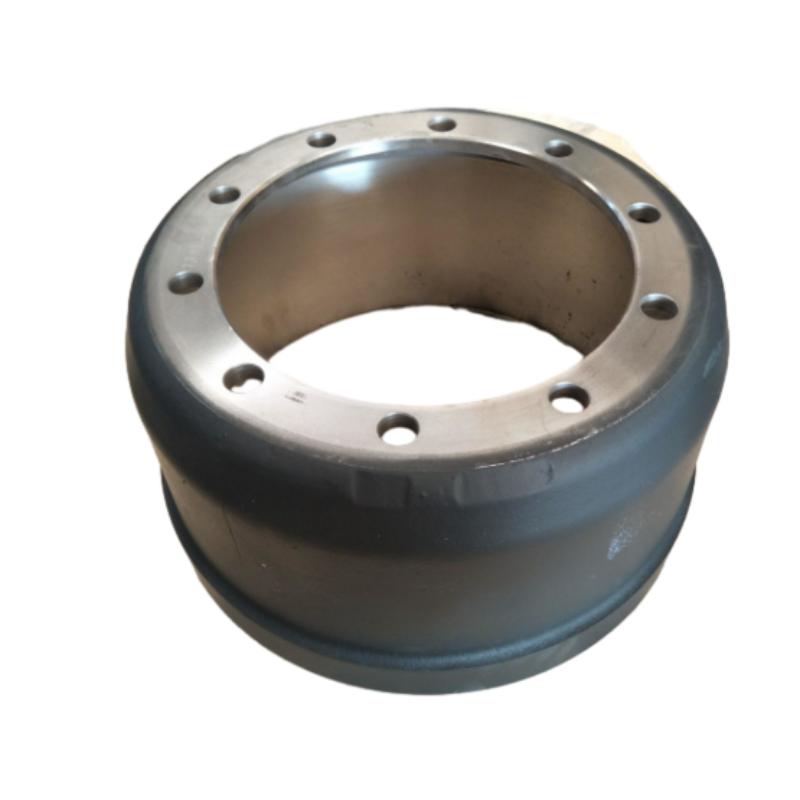

In terms of maintenance, silverback brake drums offer significant advantages. Their robust construction means less frequent replacements, and the alloy's resistance to corrosion extends their operational lifespan. However, proper care is still necessary to ensure peak performance. Regular checks for wear and tear, along with timely replacement of brake shoes, are recommended to maintain the integrity of the braking system.

As we look to the future, the evolution of silverback brake drums continues. Researchers are exploring new materials and designs that could further enhance their efficiency and longevity. With advancements in materials science and manufacturing techniques, it's possible that we may see even more improvements in weight reduction, heat management, and overall sustainability.

In conclusion, silverback brake drums represent a significant milestone in automotive safety and performance. Their journey from concept to commonplace component illustrates a relentless pursuit of innovation and improvement. As these drums continue to evolve, they promise to keep drivers safer on the roads while also pushing the boundaries of what is possible in automotive engineering.

silverback brake drums.

In terms of maintenance, silverback brake drums offer significant advantages. Their robust construction means less frequent replacements, and the alloy's resistance to corrosion extends their operational lifespan. However, proper care is still necessary to ensure peak performance. Regular checks for wear and tear, along with timely replacement of brake shoes, are recommended to maintain the integrity of the braking system.

As we look to the future, the evolution of silverback brake drums continues. Researchers are exploring new materials and designs that could further enhance their efficiency and longevity. With advancements in materials science and manufacturing techniques, it's possible that we may see even more improvements in weight reduction, heat management, and overall sustainability.

In conclusion, silverback brake drums represent a significant milestone in automotive safety and performance. Their journey from concept to commonplace component illustrates a relentless pursuit of innovation and improvement. As these drums continue to evolve, they promise to keep drivers safer on the roads while also pushing the boundaries of what is possible in automotive engineering. Latest news

-

Iveco Brake Drum | Premium OE Quality for Daily & Eurocargo

NewsAug.22,2025

-

Your Brake Drum Man: Quality & Performance Parts

NewsAug.21,2025

-

Explore Japan: Ultimate Travel Guide & Authentic Experiences

NewsAug.19,2025

-

Your Brake Drum Man: Premium & Reliable Brake Drums for Sale

NewsAug.18,2025

-

ROR Web Development: Build Fast, Scalable, Secure Apps

NewsAug.17,2025

-

Scania Brake Drums: OEM Quality for Optimal Safety & Durability

NewsAug.16,2025