feb . 13, 2025 11:01 Back to list

how do brake drums work

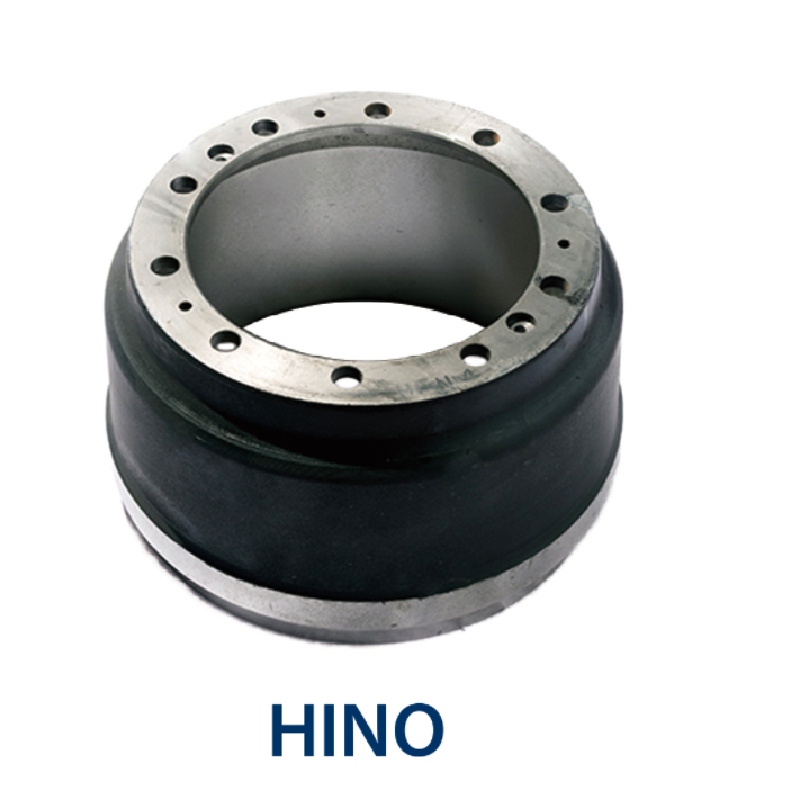

Brake drums are a vital component of the braking system in many vehicles, particularly in older models and heavier-duty trucks. Their function revolves around converting kinetic energy into heat to bring a car to a halt. Understanding how brake drums work is essential for anyone interested in automotive technology, as it allows for more informed maintenance and purchasing decisions.

In addition to regular inspections, ensuring brake drums are clean from debris and dust can prolong their lifespan. The build-up of contaminants can exacerbate wear by creating grittier friction surfaces. If the drum brake system begins to experience symptoms such as vibration, noise, or poor braking performance, it may be time to consult with a professional mechanic to assess and rectify the issue. The evolution of brake technology is continuous, and while newer vehicles are being equipped predominantly with disc brakes due to their superior performance and reliability, brake drums still hold a place in the braking systems of certain vehicle types. Their mechanical simplicity and cost-effectiveness in certain applications make them a valuable component for specific vehicles, particularly where high-torque braking is needed. From an expert standpoint, the choice between drum and disc brakes often hinges on the application requirements of the vehicle, cost considerations, and environmental conditions in which the vehicle is primarily operated. For heavy-duty applications, where the primary need may be robust stopping power over long durations, drum brakes can be particularly advantageous, despite their downsides concerning heat management. For those looking for longevity in their brake drum systems, using high-quality replacement parts can make a considerable difference. Premium materials and precise manufacturing processes aid in creating brake components that resist wear and deliver more consistent performance. Choosing a reliable brand can help mitigate risks associated with brake wear and ensure driver safety. In sum, brake drums may not have the modern appeal and efficiency of disc brakes, yet they remain a testament to the reliable engineering solutions suitable for specific automotive needs. Whether for maintaining vintage vehicles or serving specific braking functions in modern ones, brake drums are an enduring piece of automotive technology. Understanding their working mechanism is crucial for anyone interested in automotive dynamics, offering insights into the engineering choices that continue to shape our vehicles’ braking systems.

In addition to regular inspections, ensuring brake drums are clean from debris and dust can prolong their lifespan. The build-up of contaminants can exacerbate wear by creating grittier friction surfaces. If the drum brake system begins to experience symptoms such as vibration, noise, or poor braking performance, it may be time to consult with a professional mechanic to assess and rectify the issue. The evolution of brake technology is continuous, and while newer vehicles are being equipped predominantly with disc brakes due to their superior performance and reliability, brake drums still hold a place in the braking systems of certain vehicle types. Their mechanical simplicity and cost-effectiveness in certain applications make them a valuable component for specific vehicles, particularly where high-torque braking is needed. From an expert standpoint, the choice between drum and disc brakes often hinges on the application requirements of the vehicle, cost considerations, and environmental conditions in which the vehicle is primarily operated. For heavy-duty applications, where the primary need may be robust stopping power over long durations, drum brakes can be particularly advantageous, despite their downsides concerning heat management. For those looking for longevity in their brake drum systems, using high-quality replacement parts can make a considerable difference. Premium materials and precise manufacturing processes aid in creating brake components that resist wear and deliver more consistent performance. Choosing a reliable brand can help mitigate risks associated with brake wear and ensure driver safety. In sum, brake drums may not have the modern appeal and efficiency of disc brakes, yet they remain a testament to the reliable engineering solutions suitable for specific automotive needs. Whether for maintaining vintage vehicles or serving specific braking functions in modern ones, brake drums are an enduring piece of automotive technology. Understanding their working mechanism is crucial for anyone interested in automotive dynamics, offering insights into the engineering choices that continue to shape our vehicles’ braking systems.

Latest news

-

High-Quality Trailers for Towing Needs | Shop Now

NewsJul.25,2025

-

Premium MAN Shaving Kit for Effortless Comfort

NewsJul.25,2025

-

HINO Advanced Machinery Solutions - LONGYAO COUNTY YIHANG MACHINERY | Industrial Efficiency&Customization

NewsJul.21,2025

-

HINO Machinery Solutions - LONGYAO COUNTY YIHANG MACHINERY MANUFACTURING CO.LTD | Precision Engineering, Customizable Configurations

NewsJul.21,2025

-

HINO Machinery Solutions - LONGYAO COUNTY YIHANG MACHINERY MANUFACTURING CO.LTD | Precision Engineering, Customizable Configurations

NewsJul.21,2025

-

HINO Machinery Solutions - LONGYAO COUNTY YIHANG MACHINERY MANUFACTURING CO.LTD | Precision Engineering, Customizable Configurations

NewsJul.21,2025