Dec . 22, 2024 10:30 Back to list

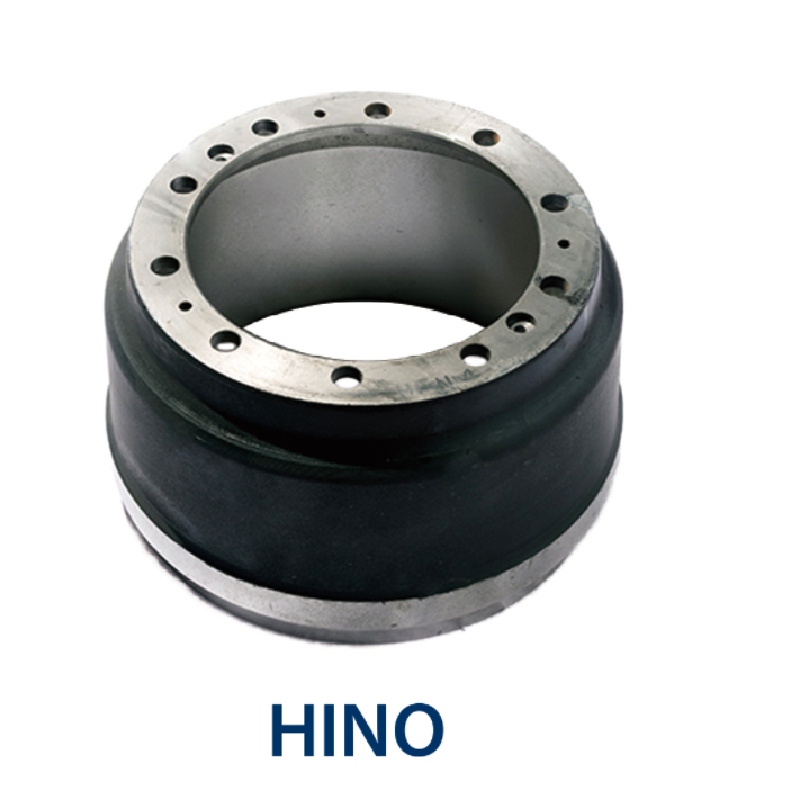

semi trailer brake drum

Understanding the Importance of Semi-Trailer Brake Drums

When it comes to heavy-duty trucking and transport, safety and efficiency are at the forefront of any operation. One crucial component that plays a vital role in the braking system of semi-trailers is the brake drum. These components are essential for ensuring that trucks can slow down and stop safely, contributing significantly to road safety.

What is a Brake Drum?

A brake drum is a cylindrical part of a drum brake system, and in the case of semi-trailers, it works alongside brake shoes and hydraulic or pneumatic force to create the necessary friction to halt the vehicle. When the driver engages the brakes, the brake shoes expand against the inner surface of the brake drum, creating a force that slows down the rotation of the wheels.

The Functionality of Brake Drums

The fundamental purpose of the brake drum is to convert kinetic energy into heat through friction. This heat is dissipated over the surface of the drum and the surrounding air. Brake drums are typically made from cast iron or aluminum, materials selected for their reliability under high temperatures.

Drum brakes have certain advantages over disc brakes, including higher tolerance for heat and better performance under heavy loads. For semi-trailers, which often carry significant loads, the use of brake drums is common because they can handle the increased demands placed on braking systems.

Maintenance of Brake Drums

Regular maintenance of brake drums is essential for ensuring they operate effectively. Wear and tear can affect their performance, leading to possible malfunction or failure. Critical maintenance steps include checking for cracks, scoring, and other signs of wear. It’s also important to inspect the brake shoes for wear, as they are one of the components that interact directly with the brake drum.

Common Issues with Brake Drums

semi trailer brake drum

Like any mechanical system, brake drums can encounter problems. Common issues include

1. Warping Overheating can lead to warping, which affects the drum's ability to create friction. 2. Cracking Excessive heat and stress can cause cracking, leading to potential brake failure.

3. Corrosion Brake drums can corrode due to exposure to moisture and road salt, which can compromise their structural integrity.

To avoid these issues, regular inspection and prompt replacement when needed are vital to maintaining road safety.

The Impact of Technology

Advances in technology have led to improved brake drum designs that enhance performance and durability. Manufacturers are now producing composite brake drums that are lighter and provide better heat dissipation. Additionally, some new technologies have been developed to allow for easier inspection and maintenance of brake drums, reducing downtime for trucking operations.

Regulations and Compliance

In many regions, brake systems, including brake drums, are subject to stringent regulations to ensure safety on the roads. These regulations may dictate minimum performance standards, required maintenance intervals, and the materials that can be used in brake systems. Trucking companies must stay informed about these regulations to ensure compliance and prioritize safety.

Conclusion

In conclusion, semi-trailer brake drums are a fundamental part of any heavy-duty trucking operation. They ensure that vehicles can stop effectively, contributing to the overall safety on the roads. Regular maintenance is necessary to prevent issues that could lead to brake failure, and technological advancements continue to improve the reliability of these crucial components. Understanding the function and importance of brake drums can help trucking companies optimize their operations while maintaining the highest safety standards.

-

Explore Japan: Ultimate Travel Guide & Authentic Experiences

NewsAug.19,2025

-

Your Brake Drum Man: Premium & Reliable Brake Drums for Sale

NewsAug.18,2025

-

ROR Web Development: Build Fast, Scalable, Secure Apps

NewsAug.17,2025

-

Scania Brake Drums: OEM Quality for Optimal Safety & Durability

NewsAug.16,2025

-

R.V.I: Advanced Remote Visual Inspection for Precision

NewsAug.15,2025

-

Discover HYUNDA: Innovative Vehicles, Equipment & Solutions

NewsAug.14,2025