Apr . 10, 2024 11:37 Back to list

What Maintenance Do Drum Brakes Need?

Postponing the maintenance of your drum brakes is a disaster waiting to happen.

By caring for your breaks with regular maintenance, you are caring for your machinery and the safety of those operating it.

It’s important to keep in mind that brakes simply don’t fail on their own. Brake failure is a direct result of negligence and improper maintenance.

So to ensure your drum brake are operating at their optimum, here’s what you need to know about their maintenance.

A Simple Guide to Drum Brake Maintenance

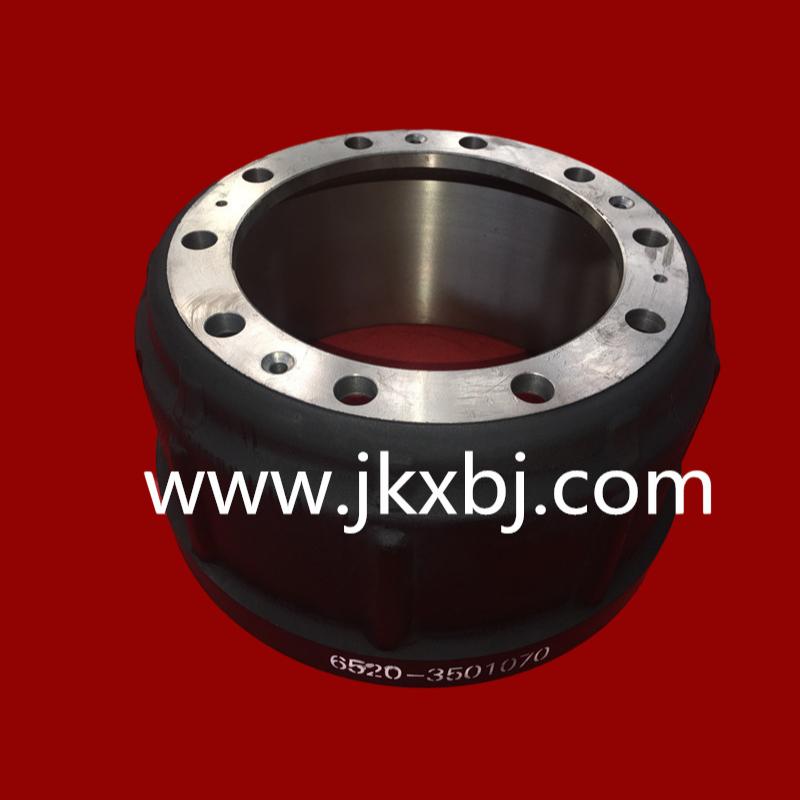

Drum brakes are comprised of a number of moving parts, so it’s essential to ensure all these parts are well-maintained.

Just some of these include hydraulic or magnetic actuators, brake drums, brake shoes, thrusters, coils, controllers and other spare parts.

To add to this, there are a number of drum brake varieties on the market, so depending on the variety, the maintenance may differ:

- DC magnetic drum brakes

- Thruster drum brakes

- DC solenoid magnetic drum brakes

- Three phase magnetic AC drum brakes

- Hydraulic drum/shoe brakes

- Handwheel drum brakes

When undergoing maintenance, you may notice that brakes require complete replacing.

In this case, remember to consider the required braking torque and correct size and model for adequate stopping power.

Wondering how to determine the torque factor of the drum brakes you need?

The drive-factor usually determines torque. Crane travel usually requires 75-100%, while 150-200% for crane hoists and overhauling loads is the norm.

The Importance of Regular Maintenance

Even if the brakes on your machinery show no visible signs of wear and tear or failure, routine maintenance every 6-months is a must.

As mentioned, waiting for brakes to fail is a disaster in the making and can put lives at risk and cost you unnecessary time and money.

Preventative maintenance is a smart move because in the long-term you will be saving yourself money while extending the life cycle of your machinery.

For these above reasons, it’s 100% necessary to incorporate drum brake maintenance into your standard operating procedures (SOP).

This way, you can educate both engineers and machine operators on the signs to look for when it comes to wear and tear and when maintenance is required.

How to Safely Replace Drum Brakes

When it comes time for drum brake maintenance, ensure your employees wear the necessary protective equipment, including an asbestos respirator.

You’ll need to ensure they are aware of all the potential hazards and how to avoid them before they begin. This is where SOP training comes in!

A simple step-by-step guide on how to replace drum brakes is as follows:

- Follow the directions to remove the machinery’s tires – this must be done before replacing drum brakes

- Make sure to double-check the brake adjuster and its screws- remove or replace as needs be

- Pull the drum brake off by holding firmly with two hands and slowly wiggling it off

- Do a thorough inspection of the drum brake before replacing with a new one

- Make sure to take a photo of the drum brake for its disassembled

- If brake shoes need replacing, make sure a comparable pair is used, i.e., they must be the same width as the previous pair

- After this, dismantle and inspect all brake components

- Replace brake pads and any faulty springs, then reassemble everything

It’s important to note that if you had to replace brake cylinders, make sure to bleed the system before the machine is used in full function again.

Looking for Specialized Industrial Parts?

Kor-Pak is a well-renowned OEM and distributor of industrial products.

We supply a range of products including heavy duty drum brakes, industrial braking systems, customized machine parts and more.

No matter the part, Kor-Pak is sure to supply it! Get in touch today to learn more about our services.

-

HINO Industrial Solutions - ¡Ң���ຽ��е��������˾ | Advanced Efficiency&Customization

NewsJul.13,2025

-

HINO Industrial Efficiency Solutions - ¡Ң���ຽ��е��������˾

NewsJul.13,2025

-

HINO Industrial Solutions - ¡Ң���ຽ��е��������˾ | Advanced Technology&Reliability

NewsJul.13,2025

-

HINO Industrial Efficiency-Jiangsu Hino Industrial|Productivity Optimization&Cost Reduction

NewsJul.12,2025

-

HINO-¡Ң���ຽ��е��������˾|Advanced Industrial Solutions&Energy Efficiency

NewsJul.12,2025

-

Premium Brake Drum Iveco – Durable Drum Brake Drum & Brake Shoe Solutions

NewsJul.08,2025