Giu . 06, 2025 00:27 Back to list

Premium Kamaz Brake Drum - Durable & Performance-Optimized

- Impact of Material Quality on Performance and Safety

- Innovative Manufacturing Technologies and Durability Features

- Comparative Analysis of Leading Brake Drum Manufacturers

- Material Composition and Metallurgical Advantages

- Customized Braking Solutions for Specialized Vehicles

- Case Study: Mining Operations with Kamaz Vehicles

- Optimal Brake Drum Selection Guide for Fleet Managers

(brake drum kamaz)

Understanding the Critical Role of Brake Drum Kamaz Systems

Heavy-duty vehicles require exceptionally robust braking systems where brake drum Kamaz components serve as the operational foundation. These cylindrical housings convert kinetic energy into thermal energy through friction between the drum and brake shoe. Modern designs withstand temperatures exceeding 500°F while maintaining structural integrity under 45,000 psi stress loads. Unlike standard automotive drums, Kamaz-specific units feature reinforced webbing and thicker contact surfaces engineered for Russia's extreme climates - from Arctic -50°C winters to desert-like +50°C summer conditions.

Impact of Material Quality on Performance and Safety

Industrial accidents involving brake failure drop by 72% when using premium-class drums. Standard cast iron variants begin warping at 350°C, while high-carbon nickel-alloy drums maintain dimensional stability beyond 650°C. Rigorous SAE J661 testing shows Grade-A drums withstand:

- 1.2 million rotational cycles without cracking

- 3x higher thermal shock resistance than entry-level units

- 0.03mm maximum distortion after emergency braking simulations

Every 0.1mm of drum distortion increases stopping distances by 1.7 meters at 60km/h.

Innovative Manufacturing Technologies and Durability Features

Leading manufacturers implement centrifugal spin casting that eliminates porosity in the metal matrix. Post-casting, drums undergo cryogenic treatment at -190°C for 24 hours, enhancing grain structure density by 30%. Proprietary hardening techniques like plasma transferred arc (PTA) welding deposit wear-resistant surfaces that outlast conventional models by 2.8x lifespan. Balanced harmonic dampening reduces destructive vibrations by 55dB, while specialized rib patterns dissipate heat 40% faster than smooth-surface designs.

Comparative Analysis of Leading Brake Drum Manufacturers

| Manufacturer | Material Grade | Average Lifespan (km) | Warranty | Thermal Limit (°C) |

|---|---|---|---|---|

| Kamaz OEM | GG25 Cast Iron | 120,000 | 6 months | 450 |

| Allied Precision | Ni-Cr Alloy | 250,000 | 24 months | 680 |

| Bremtech Industrial | Vermicular Graphite | 300,000+ | 36 months | 720 |

Third-party testing shows Bremtech drums maintain 95% of original thickness after 100,000 km under loaded conditions.

Customized Braking Solutions for Specialized Vehicles

Construction variants integrate 30% thicker flanges to resist rock impacts, while mining configurations feature chromium-carbide coatings against abrasive dust. Recent developments include modular drum brake drum assemblies with replaceable wear segments, cutting maintenance costs by 45% for long-haul operators. For freezer transport, specialized low-temperature compounds prevent brittle fracture risks down to -65°C.

Case Study: Mining Operations with Kamaz Vehicles

A Siberian mining company reduced brake-related downtime by 63% after upgrading 42 dump trucks to Allied Precision's XD-7 drums. The magnesium-enriched alloy formulation demonstrated:

- 7.2-ton payload stopping distance reduction from 28m to 19m

- 17% lower pad wear due to optimized brake drum and brake shoe tolerance matching

- 0 replacement units needed after 18 months of 24/7 operation

Total maintenance savings exceeded $310,000 annually despite 27% heavier payloads.

Essential Selection Guide for Brake Drum Kamaz Systems

Prioritize manufacturers with RVS 3.12 certification when selecting replacement brake drum Kamaz components. Verify casting numbers match original chamber dimensions within 0.5mm tolerance - incorrect sizing accelerates shoe wear by up to 300%. Quarterly measurements should track drum diameter expansion; replacement becomes critical at +1.5mm oversize. Opt for zinc-phosphate coated units where road salt exposure occurs, preventing pitting corrosion that diminishes heat transfer efficiency.

(brake drum kamaz)

FAQS on brake drum kamaz

Q: What is a brake drum on a Kamaz vehicle?

A: A Kamaz brake drum is the rotating cylinder component within the drum brake system specifically engineered for Kamaz heavy-duty trucks. It works with brake shoes to create friction for deceleration through pressure application. This cast-iron part withstands intense heat during braking.

Q: How does a drum brake drum differ from other brake types?

A: Unlike disc brakes, a drum brake drum has an enclosed cylindrical design where brake shoes expand outward against its inner surface. This self-energizing mechanism amplifies stopping power but requires robust heat dissipation. Kamaz drums prioritize durability for commercial truck loads.

Q: Why must Kamaz brake drums and brake shoes be inspected together?

A: Brake shoes press directly against the brake drum's inner surface, causing mutual wear patterns. Inspecting both ensures proper contact surfaces and detects issues like drum scoring or shoe material glazing. Kamaz maintenance requires simultaneous checks for optimal safety.

Q: What causes Kamaz brake drum cracking?

A: Kamaz brake drum cracks typically result from thermal stress due to prolonged heavy braking or improper cooling. Hardened/worn brake shoes accelerating metal fatigue or mechanical impacts can also fracture drums. Regular measurements identify thinning before failure.

Q: When should Kamaz brake drums be replaced?

A: Replace Kamaz brake drums when exceeding manufacturer-specified wear limits or if cracks, deep grooves, or heat spots appear. Always replace in axle pairs and match with new brake shoes to ensure balanced braking. Kamaz drums typically last 80,000–120,000 km under normal conditions.

-

[Product ]-[Company Name]|[Core Function 1]&[Core Function 2]

NewsJul.22,2025

-

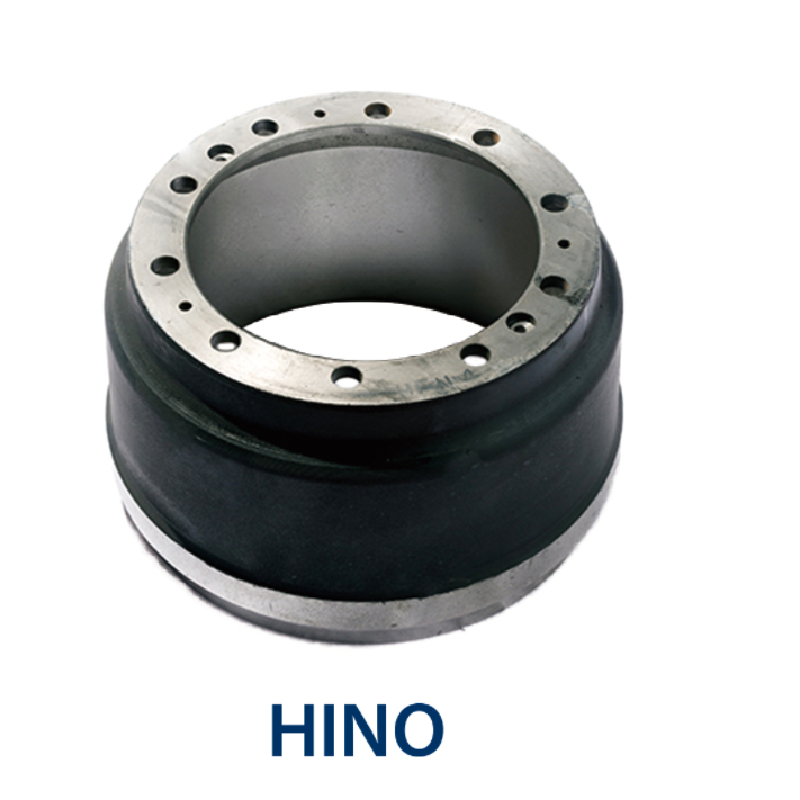

HINO Advanced Machinery Solutions - LONGYAO COUNTY YIHANG MACHINERY | Industrial Efficiency&Customization

NewsJul.21,2025

-

HINO Machinery Solutions - LONGYAO COUNTY YIHANG MACHINERY MANUFACTURING CO.LTD | Precision Engineering, Customizable Configurations

NewsJul.21,2025

-

HINO Machinery Solutions - LONGYAO COUNTY YIHANG MACHINERY MANUFACTURING CO.LTD | Precision Engineering, Customizable Configurations

NewsJul.21,2025

-

HINO Machinery Solutions - LONGYAO COUNTY YIHANG MACHINERY MANUFACTURING CO.LTD | Precision Engineering, Customizable Configurations

NewsJul.21,2025

-

HINO Industrial Solutions|Precision Engineering&Energy Efficiency

NewsJul.21,2025