Jan . 14, 2025 10:10 Back to list

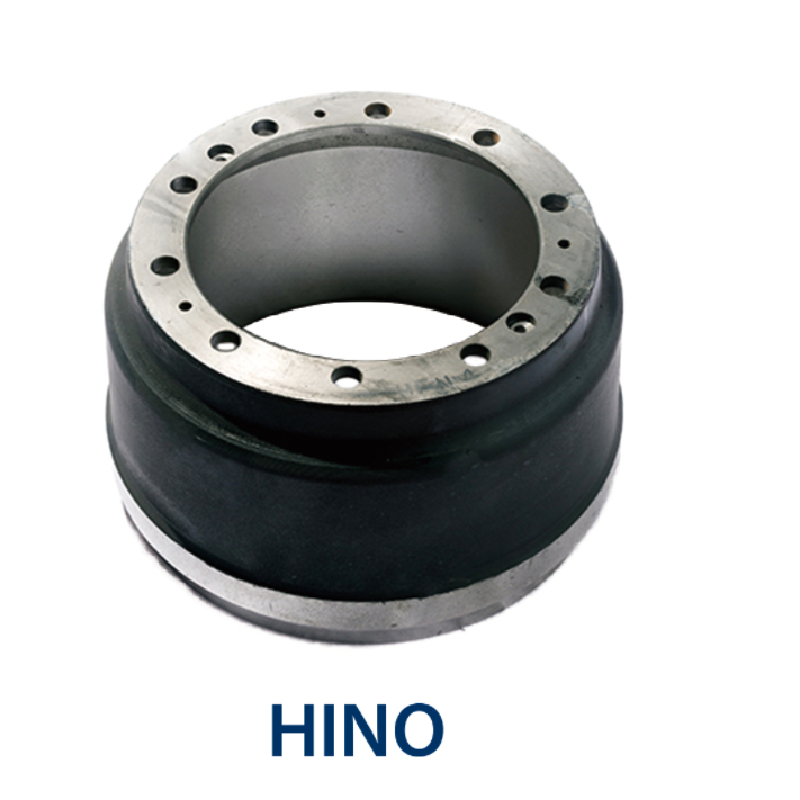

webb brake drum

Lorry brake drums are critical components for heavy equipment, ensuring safe and effective braking performance. When considering the purchase or maintenance of lorry brake drums, understanding their function, selection criteria, and the benefits of high-quality products is essential. Here, we delve into these aspects, ensuring that fleet managers and vehicle operators are informed and confident in their lorry brake drum choices.

Regular maintenance and inspection of lorry brake drums are crucial in extending their lifespan and ensuring safety. Operators should routinely check for signs of wear, such as scoring or cracking, and ensure that the drums are not warped. Warped brake drums can cause vibrations and noise, compromising the vehicle's braking efficiency. The cost-effectiveness of lorry brake drums is another consideration. While high-quality parts might come with a higher initial price tag, their durability can result in long-term savings by reducing the frequency of replacements and the risk of accidents. Understanding the balance between upfront costs and long-term value is key to making an informed purchasing decision. Trustworthy suppliers will offer warranties and customer support, which further attests to their confidence in the product reliability. A supplier's willingness to stand by their product with comprehensive support and return policies is a testament to their commitment to quality and customer satisfaction. In sum, selecting the right lorry brake drum involves understanding its material composition, precise specifications, and quality assurance. With attention to these factors, along with consideration for maintenance practices and cost-effectiveness, vehicle operators can ensure that they are equipped with safe and reliable brake drums. Such meticulous selection not only enhances driving safety but also upholds the efficiency and reputation of the fleet. By investing in high-quality lorry brake drums, operators secure peace of mind and promote the longevity and reliability of their heavy-duty vehicles.

Regular maintenance and inspection of lorry brake drums are crucial in extending their lifespan and ensuring safety. Operators should routinely check for signs of wear, such as scoring or cracking, and ensure that the drums are not warped. Warped brake drums can cause vibrations and noise, compromising the vehicle's braking efficiency. The cost-effectiveness of lorry brake drums is another consideration. While high-quality parts might come with a higher initial price tag, their durability can result in long-term savings by reducing the frequency of replacements and the risk of accidents. Understanding the balance between upfront costs and long-term value is key to making an informed purchasing decision. Trustworthy suppliers will offer warranties and customer support, which further attests to their confidence in the product reliability. A supplier's willingness to stand by their product with comprehensive support and return policies is a testament to their commitment to quality and customer satisfaction. In sum, selecting the right lorry brake drum involves understanding its material composition, precise specifications, and quality assurance. With attention to these factors, along with consideration for maintenance practices and cost-effectiveness, vehicle operators can ensure that they are equipped with safe and reliable brake drums. Such meticulous selection not only enhances driving safety but also upholds the efficiency and reputation of the fleet. By investing in high-quality lorry brake drums, operators secure peace of mind and promote the longevity and reliability of their heavy-duty vehicles.

Next:

Latest news

-

YORK GPT-4 Turbo: Fast AI for Enhanced Efficiency

NewsAug.04,2025

-

High-Performance Nissan Brake Drum | Durable Braking

NewsAug.03,2025

-

FRUEHAUF AI Trailers with GPT-4 Turbo Innovation

NewsAug.02,2025

-

TATRA: Supercharge AI with GPT-4 Turbo Technology

NewsAug.01,2025

-

2014 Mitsubishi Mirage Rear Brake Drums | Durable & Precise

NewsJul.31,2025

-

High-Quality Trailers for Towing Needs | Shop Now

NewsJul.25,2025