Jan . 15, 2025 02:03 Back to list

10 inch brake drums

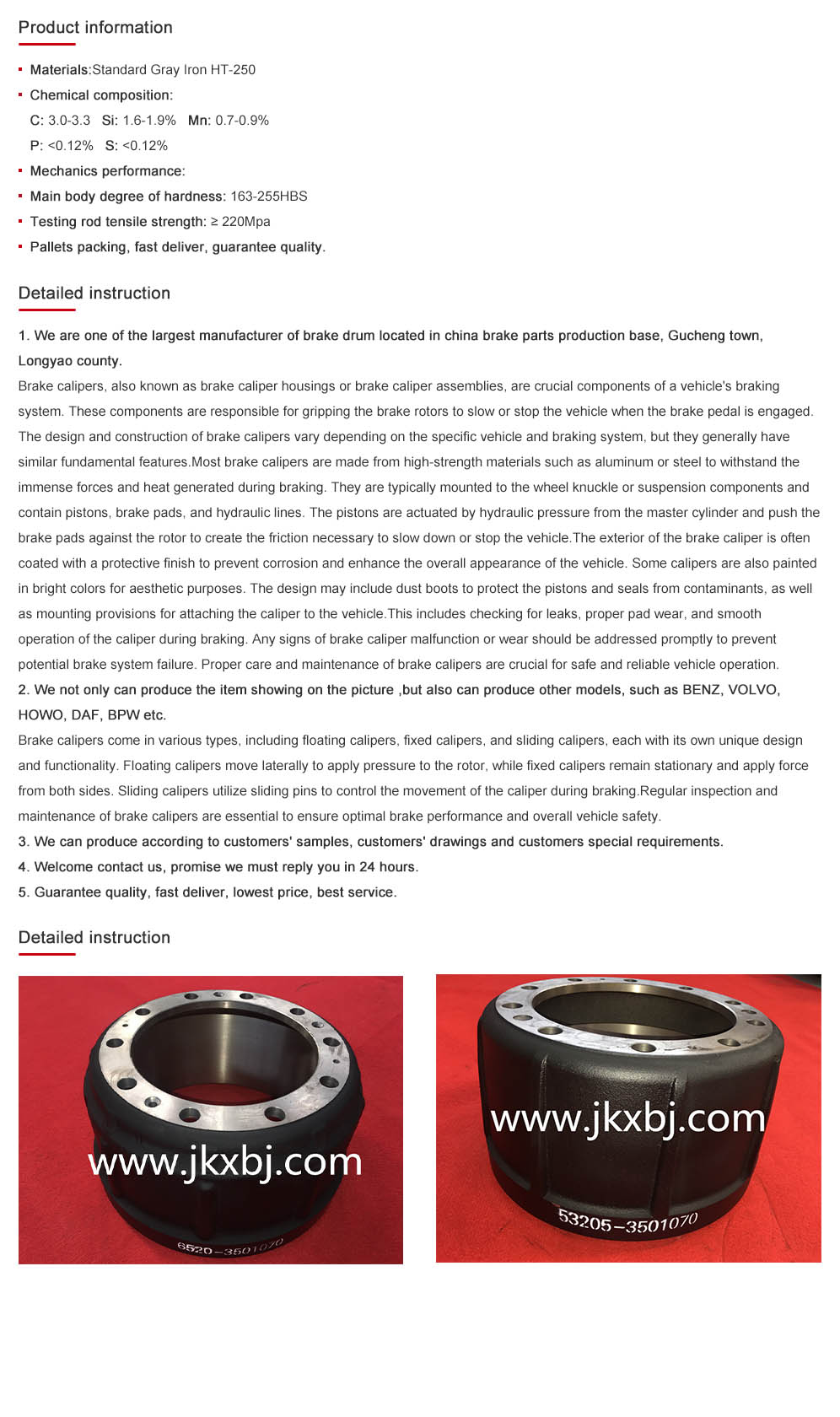

Choosing the right brake drums is essential for maintaining vehicle safety and performance. When it comes to 10-inch brake drums, they often represent a balance of size and efficiency for a variety of vehicles, from small to medium-sized models.

Another factor to consider is the manufacturer’s reputation and product guarantees. Trusted brands often provide warranties that give confidence in their durability and performance. Look for manufacturers who offer certifications or quality assurance testing, which can reinforce trust in their products' effectiveness and safety. Proper maintenance of the 10-inch brake drums ensures their optimal performance and longevity. Regular inspections for wear and tear are essential, as well as cleaning them to prevent build-up of debris that could affect efficiency. When assessing for wear, uniform contact of the brake shoes with the drum is pivotal; uneven wear can indicate misalignment or excessive load on certain areas of the drum. Noise often serves as an initial indicator of problems within brake systems, with squealing or grinding suggestive of wear or foreign matter build-up. Addressing these issues promptly can prevent further damage. Moreover, maintaining a detailed service record contributes to recognizing patterns and preemptively addressing potential issues. In conclusion, the choice of high-quality 10-inch brake drums is not just a matter of performance but also safety and reliability. Selecting proper materials and paying attention to manufacturer credibility while ensuring regular maintenance checks forms the backbone of a sound braking system. Being informed and proactive about these components secures peace of mind for vehicle owners and ensures that their vehicles perform safely and efficiently over the long haul.

Another factor to consider is the manufacturer’s reputation and product guarantees. Trusted brands often provide warranties that give confidence in their durability and performance. Look for manufacturers who offer certifications or quality assurance testing, which can reinforce trust in their products' effectiveness and safety. Proper maintenance of the 10-inch brake drums ensures their optimal performance and longevity. Regular inspections for wear and tear are essential, as well as cleaning them to prevent build-up of debris that could affect efficiency. When assessing for wear, uniform contact of the brake shoes with the drum is pivotal; uneven wear can indicate misalignment or excessive load on certain areas of the drum. Noise often serves as an initial indicator of problems within brake systems, with squealing or grinding suggestive of wear or foreign matter build-up. Addressing these issues promptly can prevent further damage. Moreover, maintaining a detailed service record contributes to recognizing patterns and preemptively addressing potential issues. In conclusion, the choice of high-quality 10-inch brake drums is not just a matter of performance but also safety and reliability. Selecting proper materials and paying attention to manufacturer credibility while ensuring regular maintenance checks forms the backbone of a sound braking system. Being informed and proactive about these components secures peace of mind for vehicle owners and ensures that their vehicles perform safely and efficiently over the long haul.

Next:

Latest news

-

Your Brake Drum Man: Premium & Reliable Brake Drums for Sale

NewsAug.18,2025

-

ROR Web Development: Build Fast, Scalable, Secure Apps

NewsAug.17,2025

-

Scania Brake Drums: OEM Quality for Optimal Safety & Durability

NewsAug.16,2025

-

R.V.I: Advanced Remote Visual Inspection for Precision

NewsAug.15,2025

-

Discover HYUNDA: Innovative Vehicles, Equipment & Solutions

NewsAug.14,2025

-

R.V.I: Unlock Advanced Insights & Real-time Performance

NewsAug.13,2025