Sep . 22, 2024 12:46 Back to list

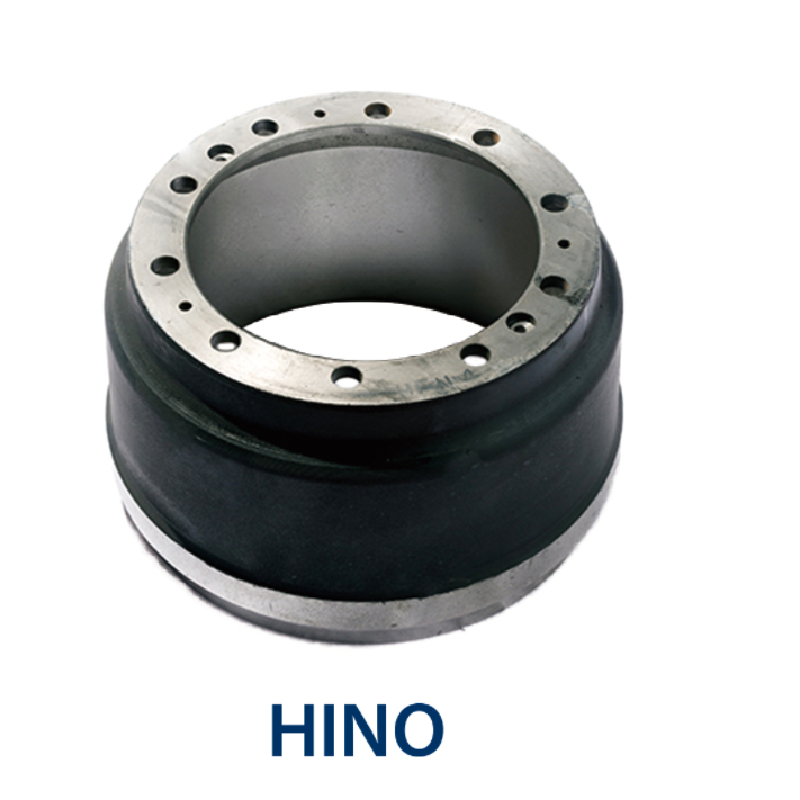

11x2 brake drums

Understanding 11x2 Brake Drums Essential Components for Safety and Performance

When it comes to vehicle safety and performance, the importance of effective braking systems cannot be overstated. Among the various components that contribute to this critical function, the 11x2 brake drums play a pivotal role, especially in older vehicles and certain types of trucks and trailers. This piece aims to illuminate the significance of these brake drums, their application, and maintenance practices to ensure optimal performance.

Firstly, it’s essential to understand what the term 11x2 brake drum signifies. The 11 refers to the diameter of the drum, which is 11 inches, while the 2 denotes the width, which is 2 inches. This specific size is commonly utilized in many light to medium-duty vehicles, providing a balance between stopping power and effective heat dissipation. The design allows for efficient contact with the brake shoes, which are crucial for generating friction when the brakes are applied.

Brake drums operate on the drum brake system, a design that has been in use for many decades. They consist of a cylindrical drum that rotates with the wheel. When the driver presses the brake pedal, hydraulic force activates the brake shoes, pressing them against the inner surface of the drum. The resulting friction slows down the vehicle. This mechanism is particularly valued for its simplicity and robustness, making it a reliable choice for many applications.

11x2 brake drums

One of the significant advantages of 11x2 brake drums is their ability to handle high levels of heat generated during braking. Continuous use can cause substantial thermal buildup, which, if not managed, can lead to brake fade—where the brakes become less effective due to overheating. The size and material composition of 11x2 brake drums allow for effective heat management, thereby maintaining brake responsiveness and extending the lifespan of the brake components.

However, like all vehicle parts, brake drums require regular maintenance to ensure their longevity and effectiveness. It’s advisable for vehicle owners to regularly inspect the brake drums for signs of wear, such as cracks or uneven surfaces. Over time, the inner surface of the drum can become grooved or hardened, which reduces contact efficiency and ultimately affects braking performance. Should any wear be detected, it may necessitate either resurfacing the drum or replacing it altogether.

Installing quality brake drums is equally important for maintaining safety and performance. Inferior drums may compromise braking efficiency and lead to premature wear. Therefore, sourcing quality parts from reputable suppliers is crucial. It's also essential for vehicle owners to adhere to the manufacturer's specifications during installation to avoid any compatibility issues that could jeopardize safety.

In summary, 11x2 brake drums serve a vital role in the braking system of various vehicles. Their design and materials are engineered to provide effective stopping power while managing heat generated during operation. Regular inspection and maintenance are paramount to ensure these components function effectively, thus enhancing both vehicle safety and performance. As automotive technology continues to evolve, the fundamental principles governing brake drum operation remain crucial for the safe and efficient operation of vehicles on the road.

-

ROR Web Development: Build Fast, Scalable, Secure Apps

NewsAug.17,2025

-

Scania Brake Drums: OEM Quality for Optimal Safety & Durability

NewsAug.16,2025

-

R.V.I: Advanced Remote Visual Inspection for Precision

NewsAug.15,2025

-

Discover HYUNDA: Innovative Vehicles, Equipment & Solutions

NewsAug.14,2025

-

R.V.I: Unlock Advanced Insights & Real-time Performance

NewsAug.13,2025

-

Kamaz Brake Drum: Durable & Reliable for Heavy Duty Trucks

NewsAug.12,2025