Dec . 13, 2024 11:51 Back to list

Understanding the Importance of a 16.62% Brake Drum for Vehicle Safety

The Importance of 16.62% Brake Drum in Automotive Engineering

In the landscape of automotive engineering, safety is paramount. Among the myriad of components that contribute to the effectiveness of vehicle operation, the brake drum is one of the most critical elements. An often underrated component, the brake drum is essential for ensuring the vehicle's braking system operates smoothly and efficiently. The analysis of brake drums often includes various statistical evaluations, and in this context, a figure of 16.62% emerges as a pivotal point of discussion.

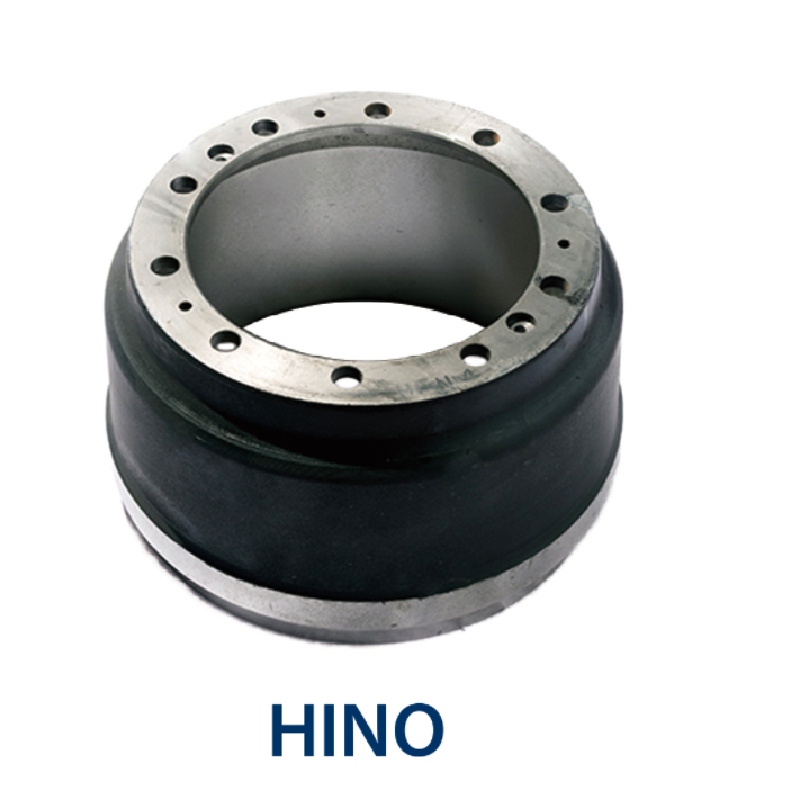

Understanding Brake Drums

A brake drum is a cylindrical component that houses the brake shoes, which press against its internal surface to create friction. This friction slows down or stops the rotation of the vehicle's wheels. Unlike disc brakes, which are more commonly used in modern vehicles, drum brakes have unique benefits, particularly in specific applications like trucks and older automobile models. Their design allows for better braking performance under certain conditions, such as in heavier vehicles or those carrying significant loads, where a larger braking surface is beneficial.

The Significance of 16.62% Measurement

The figure of 16.62% can be related to several aspects of brake drum functionality and performance. This measurement could represent various data points, such as

1. Effectiveness in Braking Performance This percentage could indicate the effectiveness of the brake drum in converting hydraulic pressure into mechanical energy, allowing for better stopping power. A brake drum that can achieve a high percentage of effective braking force is generally seen as superior, providing enhanced safety for the vehicle.

2. Wear and Tear Analysis Another interpretation of this figure might relate to the average wear experienced over time. Brake components naturally deteriorate due to friction and heat, and realizing that a brake drum typically exhibits about 16.62% wear after a significant mileage can guide maintenance schedules. Understanding this percentage helps in planning for replacements and ensuring optimal performance.

16.62 brake drum

3. Manufacturing Tolerances and Quality Control In manufacturing, maintaining consistency is vital. If a production line demonstrates a 16.62% variance in brake drum dimensions or weight, it indicates potential quality control issues that need addressing. Ensuring that brake drums fit precisely within their specifications is critical for overall brake system reliability.

4. Market Share Analysis From a business perspective, this percentage may depict the market share held by a particular manufacturer in the brake drum industry. Knowing that a specific company's brake drums account for 16.62% of sales can inform competitive strategies and marketing plans, highlighting the importance of brand reputation and product quality in the automotive sector.

The Role of Technology in Enhancing Brake Drum Performance

With advancements in technology, the design and materials used in manufacturing brake drums have considerably evolved. The introduction of lightweight alloys and composite materials helps reduce the unsprung weight of vehicles, enhancing suspension performance while maintaining robust braking capabilities. Furthermore, computer-aided engineering (CAE) has allowed for more precise modeling of stress distribution and heat dissipation within the brake drum, aiming to optimize its performance and longevity.

Conclusion

In conclusion, while a statistic like 16.62% might seem trivial at first glance, it can hold multiple layers of significance within the realm of automotive brake drum engineering. Whether it is a reflection of performance efficiency, wear metrics, manufacturing quality, or market dynamics, such data points enable engineers and manufacturers to enhance vehicle safety and reliability.

As we move forward in an industry increasingly focused on innovation and safety, understanding the nuances behind such figures will be crucial for automotive professionals. The brake drum may be a small component, but its role in vehicle operation is vital, highlighting the importance of diligent engineering and continuous improvement in the automotive field.

-

ROR Web Development: Build Fast, Scalable, Secure Apps

NewsAug.17,2025

-

Scania Brake Drums: OEM Quality for Optimal Safety & Durability

NewsAug.16,2025

-

R.V.I: Advanced Remote Visual Inspection for Precision

NewsAug.15,2025

-

Discover HYUNDA: Innovative Vehicles, Equipment & Solutions

NewsAug.14,2025

-

R.V.I: Unlock Advanced Insights & Real-time Performance

NewsAug.13,2025

-

Kamaz Brake Drum: Durable & Reliable for Heavy Duty Trucks

NewsAug.12,2025