Feb . 04, 2025 04:15 Back to list

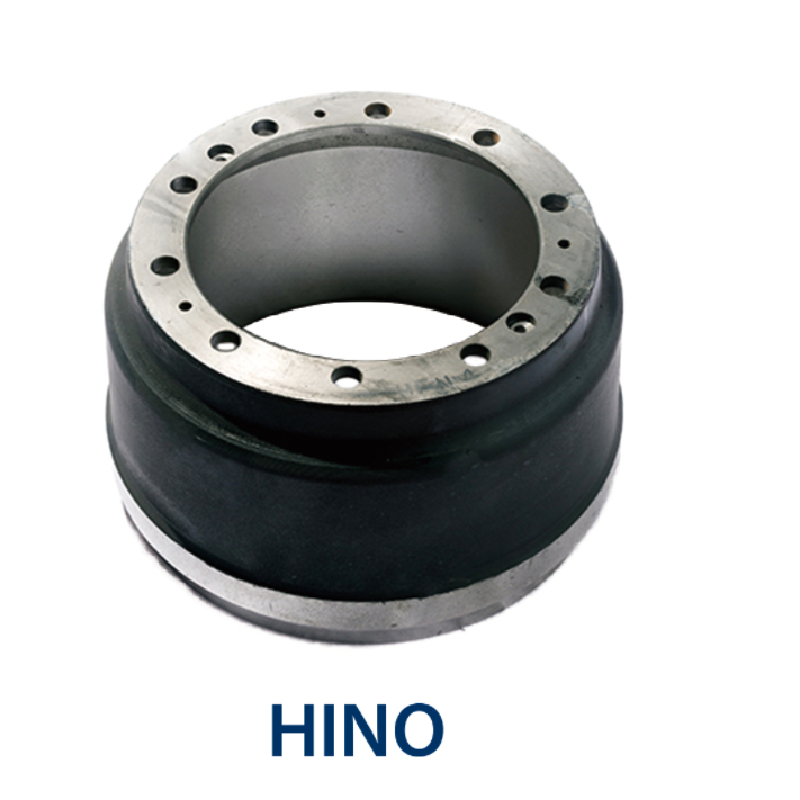

webb brake drum

The weight of an 18-wheeler brake drum is a critical factor affecting not only the performance and safety of the vehicle but also operational efficiency that impacts the bottom line of trucking operations. When selecting brake drums for an 18-wheeler, understanding the nuances of weight specifications aides in making informed purchasing decisions that optimize both safety and cost-effectiveness.

From an expert's viewpoint, conducting a detailed cost-benefit analysis when selecting drum materials is encouraged. Engaging with reputable suppliers who uphold stringent manufacturing standards ensures that any trade-offs in weight reduction do not come at the expense of safety. The application of advanced manufacturing techniques and quality control during production enhances the reliability and longevity of lighter drums, fostering trust in their use across extensive fleet operations. Authoritative sources in truck manufacturing underline compliance with federal and state regulations that specify performance standards for brake components. Adhering to these standards while optimizing drum weight is crucial to ensuring each vehicle's operational safety and legality. Seasoned logistics managers often turn to controlled field testing to gauge how variations in brake drum weight impact operational metrics like stopping distance, brake temperature stability, and component longevity. Findings from these tests provide actionable insights, informing procurement strategies that align with specific route demands, typical cargo weights, and climatic conditions experienced along service routes. Building trustworthiness with fleet operators involves transparent discussion surrounding the trade-offs associated with different drum weights. Good practices recommend comprehensive education for drivers and maintenance crews to ensure optimal utilization and servicing of brake systems relative to chosen configurations. To sum up, when examining 18-wheeler brake drum weight, experts recommend a balanced, data-driven approach encompassing material innovation, regulatory compliance, and cost-efficiency considerations. This holistic view not only safeguards the safety and reliability of the vehicle but also contributes to enhanced operational performance and profitability. Informed decisions regarding brake drum weight can significantly bolster both the competitive edge and service quality of trucking enterprises.

From an expert's viewpoint, conducting a detailed cost-benefit analysis when selecting drum materials is encouraged. Engaging with reputable suppliers who uphold stringent manufacturing standards ensures that any trade-offs in weight reduction do not come at the expense of safety. The application of advanced manufacturing techniques and quality control during production enhances the reliability and longevity of lighter drums, fostering trust in their use across extensive fleet operations. Authoritative sources in truck manufacturing underline compliance with federal and state regulations that specify performance standards for brake components. Adhering to these standards while optimizing drum weight is crucial to ensuring each vehicle's operational safety and legality. Seasoned logistics managers often turn to controlled field testing to gauge how variations in brake drum weight impact operational metrics like stopping distance, brake temperature stability, and component longevity. Findings from these tests provide actionable insights, informing procurement strategies that align with specific route demands, typical cargo weights, and climatic conditions experienced along service routes. Building trustworthiness with fleet operators involves transparent discussion surrounding the trade-offs associated with different drum weights. Good practices recommend comprehensive education for drivers and maintenance crews to ensure optimal utilization and servicing of brake systems relative to chosen configurations. To sum up, when examining 18-wheeler brake drum weight, experts recommend a balanced, data-driven approach encompassing material innovation, regulatory compliance, and cost-efficiency considerations. This holistic view not only safeguards the safety and reliability of the vehicle but also contributes to enhanced operational performance and profitability. Informed decisions regarding brake drum weight can significantly bolster both the competitive edge and service quality of trucking enterprises.

Next:

Latest news

-

Scania Brake Drums: OEM Quality for Optimal Safety & Durability

NewsAug.16,2025

-

R.V.I: Advanced Remote Visual Inspection for Precision

NewsAug.15,2025

-

Discover HYUNDA: Innovative Vehicles, Equipment & Solutions

NewsAug.14,2025

-

R.V.I: Unlock Advanced Insights & Real-time Performance

NewsAug.13,2025

-

Kamaz Brake Drum: Durable & Reliable for Heavy Duty Trucks

NewsAug.12,2025

-

Heavy Duty Iveco Brake Drum - Premium Quality & Safety

NewsAug.11,2025