Dec . 05, 2024 18:30 Back to list

Understanding the Importance of 90865 Brake Drum in Vehicle Performance and Safety

Exploring the 90865 Brake Drum Significance and Applications

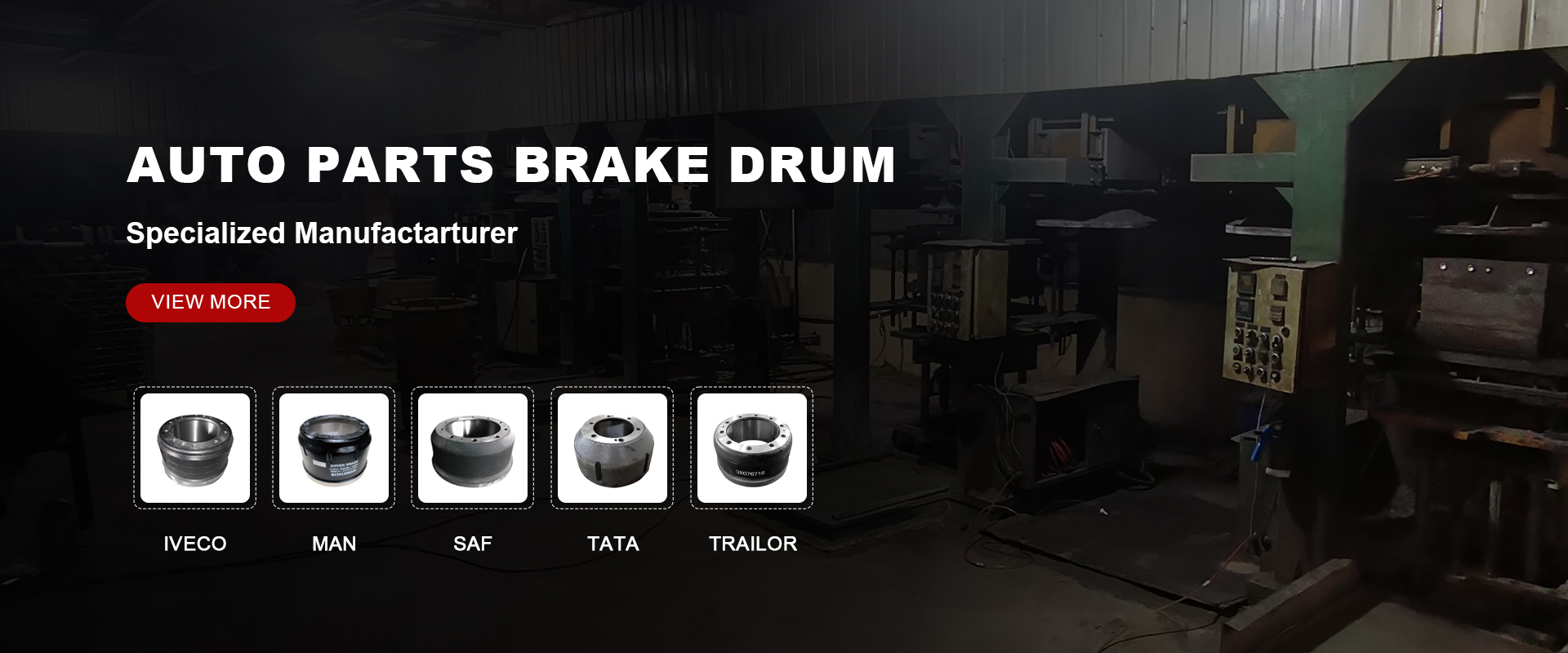

In the world of automotive engineering, the brake drum plays a crucial role in ensuring the safety and effectiveness of a vehicle's braking system. Among numerous brake drum designs, the 90865 brake drum has gained prominence for its reliability and performance characteristics. This article will delve into the engineering behind the 90865 brake drum, its applications, and the importance of maintaining brake components in optimal condition.

Understanding Brake Drums

Brake drums are essential components in drum braking systems, wherein friction is created by brake shoes pressing against the inner surface of the drum. When the driver applies the brakes, hydraulic pressure forces the brake shoes outward against the drum, generating the friction required to slow down or stop the vehicle. The efficacy of this braking action is largely dependent on the quality and design of the brake drum.

The 90865 Brake Drum Key Features

The 90865 brake drum is renowned for its robust construction and intricate engineering. Typically made from cast iron or aluminum, which provides a balance of strength and weight, this brake drum is designed to withstand the heat and stress generated during the braking process. Some key features of the 90865 brake drum include

1. Material Strength The use of high-quality materials ensures that the brake drum can endure the intense pressure and heat generated during braking, contributing to the longevity of the component.

3. Precision Engineering The inner surface of the drum is machined to precise specifications, ensuring a perfect fit with the brake shoes. This precision enhances the overall braking performance and minimizes uneven wear.

90865 brake drum

4. Compatibility The 90865 brake drum is engineered to be compatible with various vehicle models, making it a versatile choice for both manufacturers and aftermarket suppliers.

Applications of the 90865 Brake Drum

The 90865 brake drum is primarily used in various types of vehicles, including passenger cars, trucks, and certain heavy-duty applications. Its robust design makes it suitable for demanding environments, from city driving with frequent stops to highway cruising where sustained braking is necessary. Furthermore, it is often employed in vehicles that require reliable braking performance under heavy loads, such as delivery trucks and buses.

Importance of Regular Maintenance

While the 90865 brake drum is engineered for durability, regular maintenance of braking systems is essential to ensure safety and performance. Over time, brake drums can experience wear and tear, leading to issues such as

- Warping Due to excessive heat, the drum can warp, leading to uneven braking and potential vehicle instability. - Cracks Prolonged use can result in cracks, compromising the structural integrity of the drum. - Corrosion Environmental factors can cause surface rust, affecting the braking surface and overall efficiency.

To maintain optimal performance, it is recommended to conduct routine inspections of the braking system, including checking the brake drums for signs of wear. Regular replacements of brake shoes and drums, based on manufacturer recommendations and driving conditions, can significantly enhance the vehicle’s braking performance.

Conclusion

The 90865 brake drum exemplifies the intersection of engineering precision and reliability in automotive safety systems. As an essential component in the braking system, it ensures that a vehicle can safely navigate various driving conditions. Understanding its design, applications, and the importance of maintenance can help vehicle owners appreciate the critical role that brake drums play in their daily transportation. Ultimately, proactive care and timely replacements can lead to safer driving experiences and prolonged vehicle life, safeguarding not just the driver but also the occupants and others on the road.

-

HINO Industrial Solutions - ¡Ң���ຽ��е��������˾ | Advanced Technology&Reliability

NewsJul.13,2025

-

HINO Industrial Efficiency-Jiangsu Hino Industrial|Productivity Optimization&Cost Reduction

NewsJul.12,2025

-

HINO-¡Ң���ຽ��е��������˾|Advanced Industrial Solutions&Energy Efficiency

NewsJul.12,2025

-

Premium Brake Drum Iveco – Durable Drum Brake Drum & Brake Shoe Solutions

NewsJul.08,2025

-

High-Performance Brake Drum Liza for Enhanced Safety Reliable Drum Brake Drum & Brake Shoe Solutions

NewsJul.08,2025

-

High-Quality Brake Drum MAZ – Durable Drum Brake Drum & Brake Drum and Brake Shoe for Optimal Performance

NewsJul.07,2025