Sep . 15, 2024 06:19 Back to list

brake drums and shoes for semi truck

Understanding Brake Drums and Shoes for Semi Trucks

When it comes to the safe operation of semi trucks, one of the most critical components is the brake system. Among the various parts that ensure a truck can stop effectively, brake drums and shoes play a pivotal role. Understanding how these components function and their significance in the overall brake system can help in maintaining the safety and performance of semi trucks.

What Are Brake Drums and Shoes?

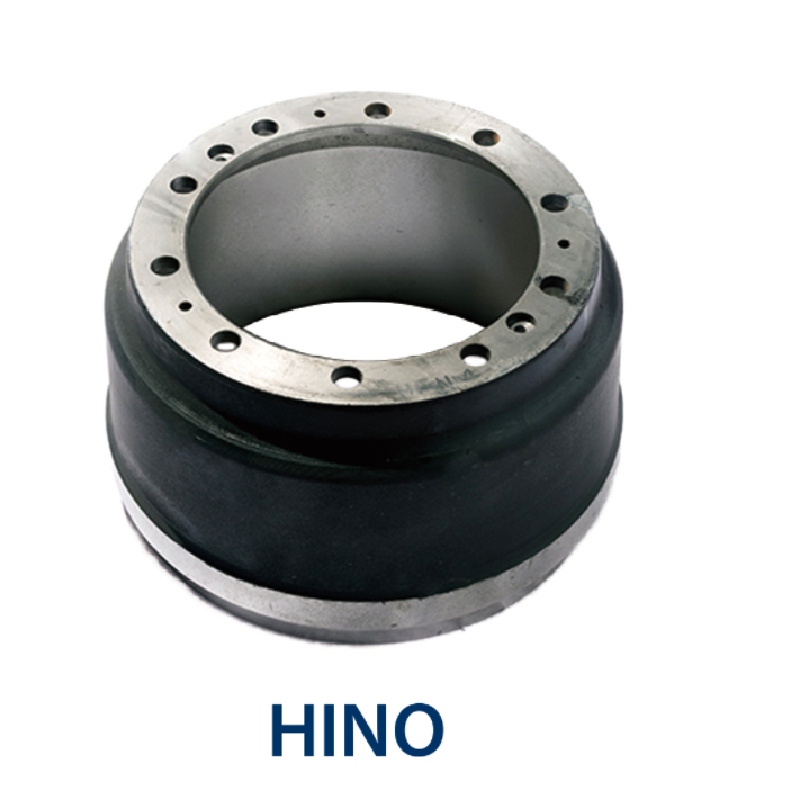

Brake drums are large, cylindrical components that are attached to the wheels of the semi truck. When the driver applies the brake pedal, the brake shoes are forced against the inner surface of the brake drum. This friction generates the necessary force to slow down or stop the vehicle. Brake drums are typically made of cast iron or steel, materials chosen for their durability and heat resistance.

Brake shoes, on the other hand, are the actual friction components in the system, lined with a material designed to resist wear and provide effective stopping power. They come in various designs tailored to fit specific brake drums and are essential for ensuring a proper fit and effective performance.

Importance of Brake Drums and Shoes

1. Safety The most crucial function of brake drums and shoes is to ensure the truck can stop safely. With heavy loads and high speeds, semi trucks require reliable brake systems. Worn or damaged drums and shoes can lead to diminished stopping power, increasing the risk of accidents.

2. Performance Properly functioning brake drums and shoes contribute to better overall performance of the truck. They help maintain traction and stability, particularly during challenging driving conditions, such as wet or icy roads. Regular inspection and replacement of these components help keep the brake system responsive.

brake drums and shoes for semi truck

3. Cost-Efficiency Well-maintained brake drums and shoes can save truck owners money in the long run. By avoiding premature wear and damage through regular checks, truck operators can prevent costly repairs or replacements. Furthermore, effective brakes improve fuel efficiency, as a truck that can stop smoothly and reliably often requires less energy to operate.

Maintenance Tips

To ensure that brake drums and shoes perform optimally, regular maintenance is essential. Here are some tips

- Routine Inspections Check brake drums and shoes for signs of wear, such as cracks or excessive scoring. Regularly inspecting these components can help catch issues before they become serious problems.

- Proper Adjustment Hydraulic and air brake systems need to be properly adjusted to ensure the brake shoes make adequate contact with the drums. Poor adjustment can lead to uneven wear and compromised stopping power.

- Environment Considerations If a truck operates in harsher conditions—like frequent stop-and-go traffic or rough terrains—inspect brakes more often. Dust, dirt, and moisture can significantly affect brake performance.

In conclusion, brake drums and shoes are vital components of a semi truck's braking system. Their maintenance and timely replacement are essential for ensuring safety and performance on the road. By understanding these components better, truck owners and operators can make informed decisions that contribute to their fleet's overall efficiency and longevity.

-

Scania Brake Drums: OEM Quality for Optimal Safety & Durability

NewsAug.16,2025

-

R.V.I: Advanced Remote Visual Inspection for Precision

NewsAug.15,2025

-

Discover HYUNDA: Innovative Vehicles, Equipment & Solutions

NewsAug.14,2025

-

R.V.I: Unlock Advanced Insights & Real-time Performance

NewsAug.13,2025

-

Kamaz Brake Drum: Durable & Reliable for Heavy Duty Trucks

NewsAug.12,2025

-

Heavy Duty Iveco Brake Drum - Premium Quality & Safety

NewsAug.11,2025