Feb . 17, 2025 14:59 Back to list

Mitsubishi Lancer Rear Drum Brakes

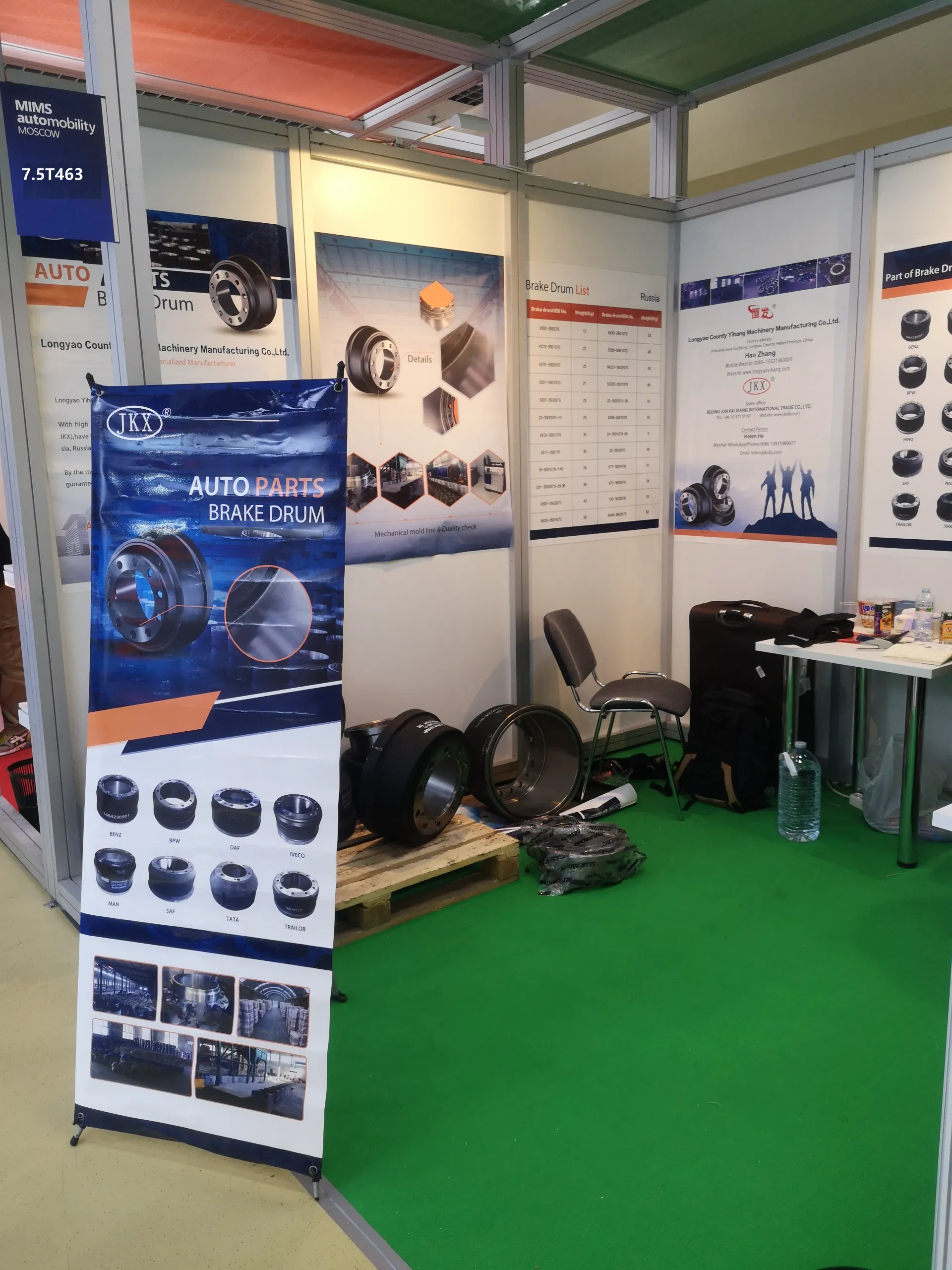

Trucks are the lifeline of many industries, acting as the crucial connectors between suppliers and consumers. Within these mechanical giants, the brake drum constitutes an essential component that directly influences both performance and safety. In the world of heavy-duty trucking, understanding the nuances of brake drums and their function is vital for operators and fleet managers aiming for reliability and efficiency.

Selecting the right brake drum for a truck involves consideration of several factors load capacity, type of cargo, typical routes, and even climate conditions. For instance, fleets operating in mountainous regions might prioritize drums with superior heat tolerance due to frequent braking, whereas trucks with long highway routes might prioritize weight to maximize fuel efficiency. Reputable manufacturers provide comprehensive data sheets detailing the mechanical properties, compatibility, and specific applications of their brake drums, underscoring the importance of sourcing parts from trusted suppliers. Industry certifications also play a crucial role; parts adhering to recognizable standards such as the Society of Automotive Engineers (SAE) or the American Society for Testing and Materials (ASTM) offer an assurance of quality and reliability. Trustworthiness in a brake drum vendor extends beyond product quality to customer service and support. Responsive, knowledgeable support teams and clear return policies build trust, ensuring operators can get back on the road with minimal downtime should complications arise. In conclusion, brake drums for trucks are not mere mechanical components but integral pieces of a larger safety and efficiency puzzle. Through informed material selection, rigorous maintenance, and reliance on reputable manufacturers, fleet operators can ensure that their braking systems remain reliable and responsive across countless miles and diverse terrains. As the trucking industry continues to evolve, those who align their practices with expertise, authority, and trustworthiness will drive both their vehicles and their ventures toward success.

Selecting the right brake drum for a truck involves consideration of several factors load capacity, type of cargo, typical routes, and even climate conditions. For instance, fleets operating in mountainous regions might prioritize drums with superior heat tolerance due to frequent braking, whereas trucks with long highway routes might prioritize weight to maximize fuel efficiency. Reputable manufacturers provide comprehensive data sheets detailing the mechanical properties, compatibility, and specific applications of their brake drums, underscoring the importance of sourcing parts from trusted suppliers. Industry certifications also play a crucial role; parts adhering to recognizable standards such as the Society of Automotive Engineers (SAE) or the American Society for Testing and Materials (ASTM) offer an assurance of quality and reliability. Trustworthiness in a brake drum vendor extends beyond product quality to customer service and support. Responsive, knowledgeable support teams and clear return policies build trust, ensuring operators can get back on the road with minimal downtime should complications arise. In conclusion, brake drums for trucks are not mere mechanical components but integral pieces of a larger safety and efficiency puzzle. Through informed material selection, rigorous maintenance, and reliance on reputable manufacturers, fleet operators can ensure that their braking systems remain reliable and responsive across countless miles and diverse terrains. As the trucking industry continues to evolve, those who align their practices with expertise, authority, and trustworthiness will drive both their vehicles and their ventures toward success.

Latest news

-

Scania Brake Drums: OEM Quality for Optimal Safety & Durability

NewsAug.16,2025

-

R.V.I: Advanced Remote Visual Inspection for Precision

NewsAug.15,2025

-

Discover HYUNDA: Innovative Vehicles, Equipment & Solutions

NewsAug.14,2025

-

R.V.I: Unlock Advanced Insights & Real-time Performance

NewsAug.13,2025

-

Kamaz Brake Drum: Durable & Reliable for Heavy Duty Trucks

NewsAug.12,2025

-

Heavy Duty Iveco Brake Drum - Premium Quality & Safety

NewsAug.11,2025