Oct . 31, 2024 23:19 Back to list

Guidelines for Accurate Measurement of Brake Drum Dimensions and Specifications

Brake Drum Measurement Ensuring Safety and Performance in Vehicles

Brake drums are a critical component of a vehicle's braking system, particularly in older or heavier vehicles. Understanding how to measure brake drums accurately is essential for both maintaining safety and enhancing the performance of the braking system. This article will delve into the importance of brake drum measurement, the tools required, and the steps involved in the process.

Brake drums function by providing a friction surface where brake shoes press against them to slow down or stop the vehicle. Over time, these drums can wear down due to constant friction, heat, and the accumulation of dust and debris, which may lead to reduced braking efficiency and safety hazards. Therefore, regular measurement is vital to ensure they remain within manufacturer specifications and function correctly.

To measure brake drums, you will need a few essential tools a micrometer or caliper, a dial gauge, and a brake drum gauge. Each tool serves its purpose, allowing for precise measurements of the drum's diameter, wall thickness, and overall condition.

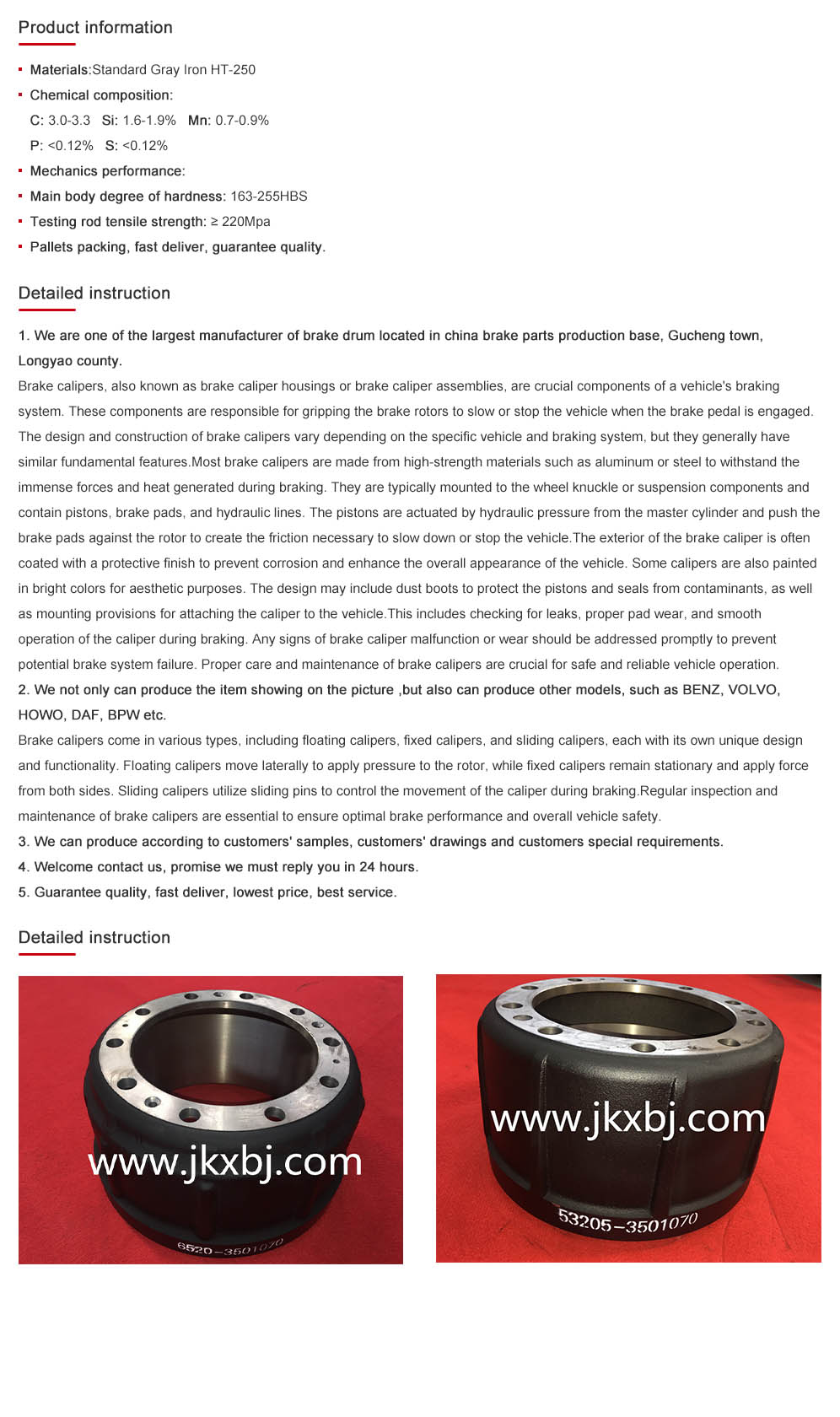

brake drum measurement

The first step in measuring a brake drum is to clean the surface thoroughly to remove any dirt or debris. This ensures that your measurements will be accurate. Next, using a micrometer or caliper, measure the diameter of the brake drum at several points around its circumference. This is important as drums can wear unevenly, and taking multiple measurements helps identify any areas that are excessively worn or out of round.

Once the diameter is established, measuring the wall thickness using a brake drum gauge is beneficial. The minimum wall thickness is specified by the manufacturer, and it is crucial to ensure that the drum has not worn below this limit. If the drum is found to be too thin, it may need to be replaced to maintain optimal braking performance.

Another important measurement is checking for any signs of warping. This can be done by attaching a dial gauge to the drum and rotating it. Any significant deviation in measurement indicates that the drum is warped and should either be resurfaced if within specifications or replaced.

In conclusion, accurate brake drum measurement is imperative for vehicle safety and optimal braking performance. Regular checks and maintenance can help prevent costly repairs and ensure that vehicles operate efficiently. By using the right tools and following proper procedures, automotive technicians can ensure that brake drums remain in good condition, providing peace of mind for drivers on the road. Proper measurement and maintenance not only enhance vehicle reliability but also contribute to overall road safety.

-

Your Brake Drum Man: Premium & Reliable Brake Drums for Sale

NewsAug.18,2025

-

ROR Web Development: Build Fast, Scalable, Secure Apps

NewsAug.17,2025

-

Scania Brake Drums: OEM Quality for Optimal Safety & Durability

NewsAug.16,2025

-

R.V.I: Advanced Remote Visual Inspection for Precision

NewsAug.15,2025

-

Discover HYUNDA: Innovative Vehicles, Equipment & Solutions

NewsAug.14,2025

-

R.V.I: Unlock Advanced Insights & Real-time Performance

NewsAug.13,2025