Oct . 20, 2024 15:57 Back to list

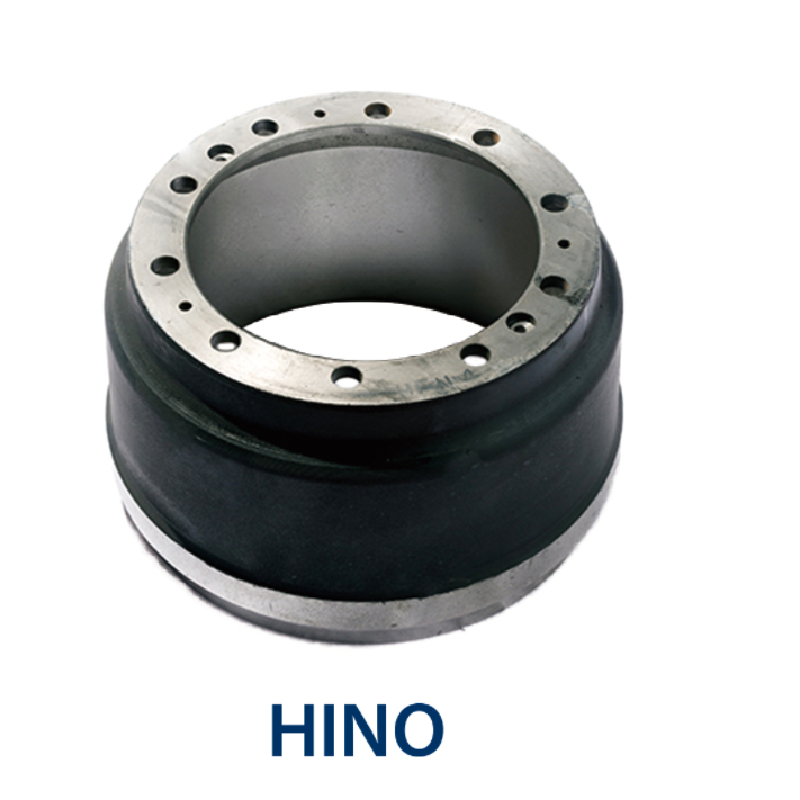

brake drum on truck

Understanding Brake Drums on Trucks Importance and Maintenance

When it comes to the safety and efficiency of heavy-duty trucks, the brake system is paramount. Central to this system is the brake drum, a critical component that plays a significant role in the vehicle's stopping power. This article aims to elucidate the importance of brake drums in trucks and provide insights into their maintenance.

What is a Brake Drum?

A brake drum is a cylindrical component of the drum brake system, which is commonly used in trucks, particularly those that transport heavy loads. When the driver applies the brakes, brake shoes press against the inside surface of the drum, creating friction that slows down or stops the vehicle. The design of brake drums allows them to dissipate heat effectively, improving performance and extending their lifespan compared to other brake systems.

Importance of Brake Drums

1. Safety The primary role of brake drums is to ensure the safety of the vehicle and its passengers. Trucks often travel at high speeds and carry significant weights, making powerful and reliable braking essential. If the brake drums are not functioning correctly, it can lead to increased stopping distances, reduced control, and a greater risk of accidents.

2. Durability Brake drums are designed to handle extreme conditions, including heavy loads and high temperatures. This durability is vital for trucks that frequently operate in tough environments, such as construction sites or long-haul interstate travel.

3. Cost-Effectiveness While the initial cost of maintenance may seem high, investing in quality brake drums can save money in the long run. Well-maintained brake drums can last longer and perform better, reducing the frequency of repairs and replacements.

Maintenance of Brake Drums

brake drum on truck

To ensure optimal performance and longevity of brake drums, regular maintenance is key. Here are some essential maintenance practices

1. Regular Inspections Truck drivers and fleet managers should conduct regular inspections of the brake system, focusing on the brake drums. This includes checking for wear and tear, cracks, or any signs of overheating. Ideally, inspections should occur every 6,000 to 10,000 miles or as recommended by the manufacturer.

2. Proper Adjustment Brake adjustment is crucial in maintaining the efficiency of the braking system. As brake shoes wear down, they need to be adjusted to ensure they remain in contact with the drum effectively. An improperly adjusted braking system can lead to uneven wear, reducing the lifespan of both the drums and shoes.

3. Replacement Brake drums do eventually wear out, and it's essential to replace them before they become too damaged. Signs that a brake drum needs replacement include excessive scoring, cracks, or a warped shape. Continuing to use defective brake drums can compromise braking performance and safety.

4. Heat Management Overheating can be a significant issue with brake drums, especially under heavy loads or during prolonged braking. Ensuring that the brakes are not overly engaged—such as during long descents—can help prevent overheating. Additionally, using a proper braking technique can mitigate excessive heat generation.

5. Use Quality Parts When replacing brake drums, opting for high-quality aftermarket or OEM (Original Equipment Manufacturer) parts can make a significant difference in performance and safety. Quality components are often more reliable and can withstand the rigors of heavy-duty use.

Conclusion

In conclusion, brake drums are a vital component of a truck's braking system, playing a crucial role in ensuring safety and reliability. Regular maintenance, including inspections, adjustments, and timely replacements, is essential for optimal brake performance. By prioritizing the health of the brake system, truck operators can enhance safety, reduce costs, and improve the overall efficiency of their vehicles. Keeping a close eye on brake drums not only protects the investment in the truck but also safeguards the lives of those on the road.

-

HINO Industrial Solutions - ¡Ң���ຽ��е��������˾ | Advanced Efficiency&Customization

NewsJul.13,2025

-

HINO Industrial Efficiency Solutions - ¡Ң���ຽ��е��������˾

NewsJul.13,2025

-

HINO Industrial Solutions - ¡Ң���ຽ��е��������˾ | Advanced Technology&Reliability

NewsJul.13,2025

-

HINO Industrial Efficiency-Jiangsu Hino Industrial|Productivity Optimization&Cost Reduction

NewsJul.12,2025

-

HINO-¡Ң���ຽ��е��������˾|Advanced Industrial Solutions&Energy Efficiency

NewsJul.12,2025

-

Premium Brake Drum Iveco – Durable Drum Brake Drum & Brake Shoe Solutions

NewsJul.08,2025