Oct . 11, 2024 14:18 Back to list

Brake Drum Machining Equipment for Precision Metalworking and Efficient Performance

Understanding the Brake Drum Turning Machine A Vital Tool in Automotive Maintenance

In the arena of automotive repair and maintenance, the brake system plays a crucial role in ensuring vehicle safety and performance. Among the essential components of this system are the brake drums, which require regular inspection and maintenance to function effectively. An important tool that aids in this maintenance is the brake drum turning machine. This machine is designed specifically to restore the surface of worn or damaged brake drums, ensuring they perform optimally.

The Importance of Brake Drum Maintenance

Brake drums can experience wear over time due to friction between the drum and brake shoes. This wear can lead to several issues, including reduced braking efficiency, noise, and vibrations while braking. In more severe cases, uneven wear can result in brake failure, posing serious risks to driver safety. To prevent these issues, automotive technicians often turn to brake drum turning machines to refurbish these critical components.

How Brake Drum Turning Machines Work

A brake drum turning machine works by grinding away a thin layer of material from the surface of the drum, effectively creating a smooth and even surface. The process begins with the technician carefully mounting the brake drum onto the machine. Once secured, the machine spins the drum at a controlled speed while a cutting tool removes the worn material. This operation not only improves the surface finish but also restores the drum’s original dimensions, ensuring an optimal fit with the brake shoes.

Most modern drum turning machines are equipped with advanced features, including digital readouts and adjustable speed controls, allowing for precise operation. Some machines even feature automatic feed systems, which enhance efficiency and reduce the risk of operator error.

brake drum turning machine

Advantages of Using a Brake Drum Turning Machine

1. Enhanced Safety Regularly turning brake drums can significantly improve vehicle safety by ensuring that brakes function reliably. A smooth drum surface allows for better contact with the brake shoes, leading to increased stopping power and reduced stopping distances.

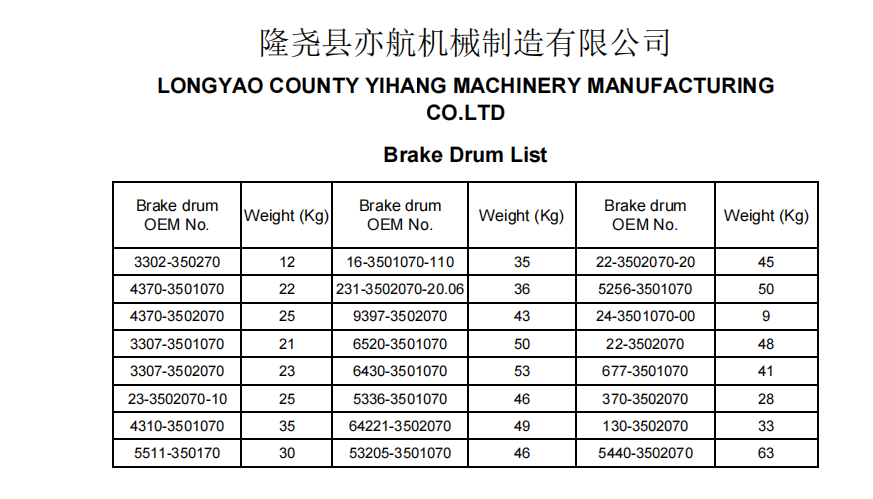

2. Cost-Effectiveness Refurbishing brake drums with a turning machine can be more economical than replacing them entirely. This is particularly beneficial for older vehicles where original equipment manufacturer (OEM) parts may be difficult to procure.

3. Environmental Benefits By extending the life of existing brake drums, turning machines contribute to reducing waste. Fewer parts need to be manufactured and discarded, aligning with sustainable practices in automotive maintenance.

4. Improved Vehicle Performance A well-maintained brake system enhances overall vehicle performance. By ensuring that brake drums are in optimal condition, drivers can experience smoother and more responsive braking.

Conclusion

In conclusion, the brake drum turning machine is a vital piece of equipment in the automotive industry, serving to restore one of the most critical components of a vehicle's braking system. With safety, cost-effectiveness, and performance benefits, this machine plays an essential role in vehicle maintenance. As technology continues to advance, we can expect further innovations in brake drum refurbishment techniques, allowing for even more efficient and effective solutions for automotive professionals. By prioritizing regular maintenance and using the right tools, such as the brake drum turning machine, technicians can ensure that vehicles remain safe and reliable for all road users.

-

Scania Brake Drums: OEM Quality for Optimal Safety & Durability

NewsAug.16,2025

-

R.V.I: Advanced Remote Visual Inspection for Precision

NewsAug.15,2025

-

Discover HYUNDA: Innovative Vehicles, Equipment & Solutions

NewsAug.14,2025

-

R.V.I: Unlock Advanced Insights & Real-time Performance

NewsAug.13,2025

-

Kamaz Brake Drum: Durable & Reliable for Heavy Duty Trucks

NewsAug.12,2025

-

Heavy Duty Iveco Brake Drum - Premium Quality & Safety

NewsAug.11,2025