Nov . 08, 2024 21:12 Back to list

brake drum wheel cylinder

Understanding Brake Drum Wheel Cylinders A Comprehensive Overview

When it comes to vehicle braking systems, understanding the components that contribute to safety and efficiency is crucial. One of the key elements in many braking systems, especially in older vehicles and certain types of trucks, is the brake drum wheel cylinder. This component plays a vital role in ensuring that the vehicle can slow down or stop effectively. In this article, we will delve into the function and importance of brake drum wheel cylinders, how they work, and some common maintenance practices.

What is a Brake Drum Wheel Cylinder?

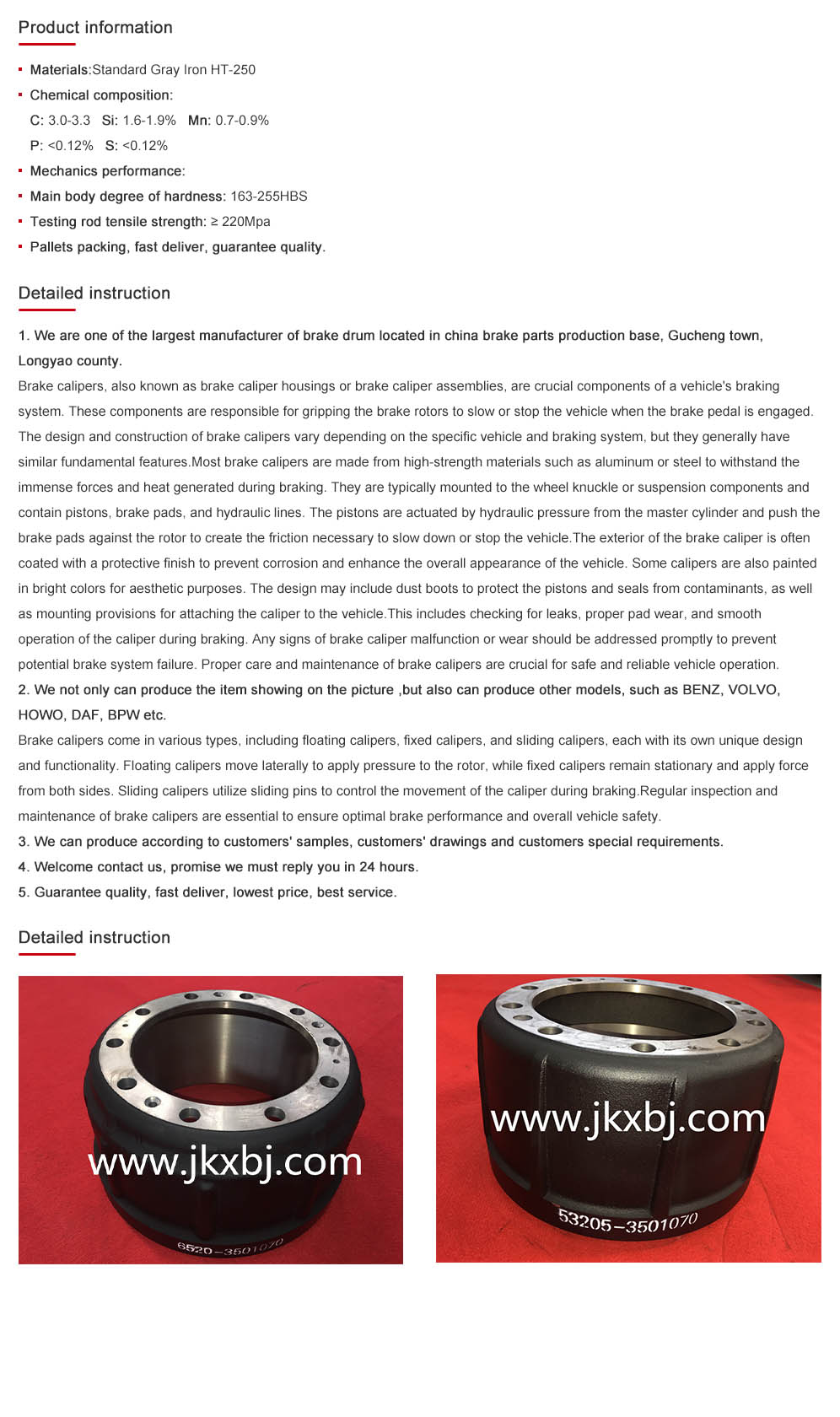

The brake drum wheel cylinder is part of the drum brake system, which operates using a drum and brake shoes. Located inside each brake drum, this cylinder is typically made of cast iron or aluminum and houses pistons that push the brake shoes against the drum to create friction, thereby slowing down or stopping the vehicle.

The brake drum itself is a circular metal component that rotates along with the wheel, while the brake shoes are curved pieces of material lined with friction material. When the driver presses the brake pedal, hydraulic fluid is sent to the wheel cylinder, causing the pistons to move outward. This action forces the brake shoes against the inner surface of the brake drum, creating the necessary friction to halt the wheel's movement.

The Importance of Brake Drum Wheel Cylinders

One of the primary reasons brake drum wheel cylinders are significant is their reliability and effectiveness in generating braking force. Compared to disc brakes, drum brakes offer a larger surface area for friction, which can be advantageous in certain applications, particularly for heavy-duty vehicles. Furthermore, brake drum systems are generally simpler and can be more cost-effective in terms of initial installation.

However, it is essential to note that drum brakes can be prone to overheating and fading under excessive use, such as during heavy braking or prolonged descents. The design of the brake drum wheel cylinder allows it to handle significant hydraulic pressure, providing vital braking assistance even under demanding conditions.

brake drum wheel cylinder

How Do Brake Drum Wheel Cylinders Work?

The operation of a brake drum wheel cylinder is based on the principles of hydraulics. When the brake pedal is pressed, a master cylinder generates hydraulic pressure that moves hydraulic fluid through the brake lines toward the wheel cylinders. Each wheel cylinder contains one or two pistons that are pushed outward by this pressure when the fluid enters the cylinder.

As the pistons extend, they push the brake shoes against the inner surface of the brake drum. The friction generated by this contact slows the wheel's rotation. The wheel cylinder must move the shoes a specific distance to ensure effective braking. After the brake pedal is released, the hydraulic pressure decreases, allowing the springs inside the assembly to retract the shoes away from the drum, thus allowing the wheels to turn freely again.

Maintenance and Common Issues

Proper maintenance of brake drum wheel cylinders is essential for ensuring safe vehicle operation. Regular inspection of the braking system allows for detection of any issues, such as leaking brake fluid, corroded components, or worn-out brake shoes. Common symptoms of malfunctioning wheel cylinders include diminished braking performance, spongy brake pedals, and visible brake fluid leaks around the drums.

During maintenance, it is advisable to check the brake fluid level and quality regularly. Old or contaminated fluid can lead to internal corrosion and failure of the wheel cylinder, so it’s crucial to replace it as needed. Additionally, when replacing brake shoes or drums, it’s wise to inspect the wheel cylinders to ensure they are in good condition and functioning properly.

Conclusion

The brake drum wheel cylinder may be a small component within the larger braking system, but its role is immeasurable when it comes to vehicle safety. Understanding how it operates, recognizing the signs of wear, and performing routine maintenance can go a long way in ensuring a safe driving experience. Whether you drive a classic car, a heavy-duty truck, or a more modern vehicle equipped with a drum brake system, appreciating the significance of this component is key to proactive vehicle management. By ensuring that your brake drum wheel cylinders are in optimal condition, you can contribute to both your safety and that of others on the road.

-

Scania Brake Drums: OEM Quality for Optimal Safety & Durability

NewsAug.16,2025

-

R.V.I: Advanced Remote Visual Inspection for Precision

NewsAug.15,2025

-

Discover HYUNDA: Innovative Vehicles, Equipment & Solutions

NewsAug.14,2025

-

R.V.I: Unlock Advanced Insights & Real-time Performance

NewsAug.13,2025

-

Kamaz Brake Drum: Durable & Reliable for Heavy Duty Trucks

NewsAug.12,2025

-

Heavy Duty Iveco Brake Drum - Premium Quality & Safety

NewsAug.11,2025