Sep . 23, 2024 01:13 Back to list

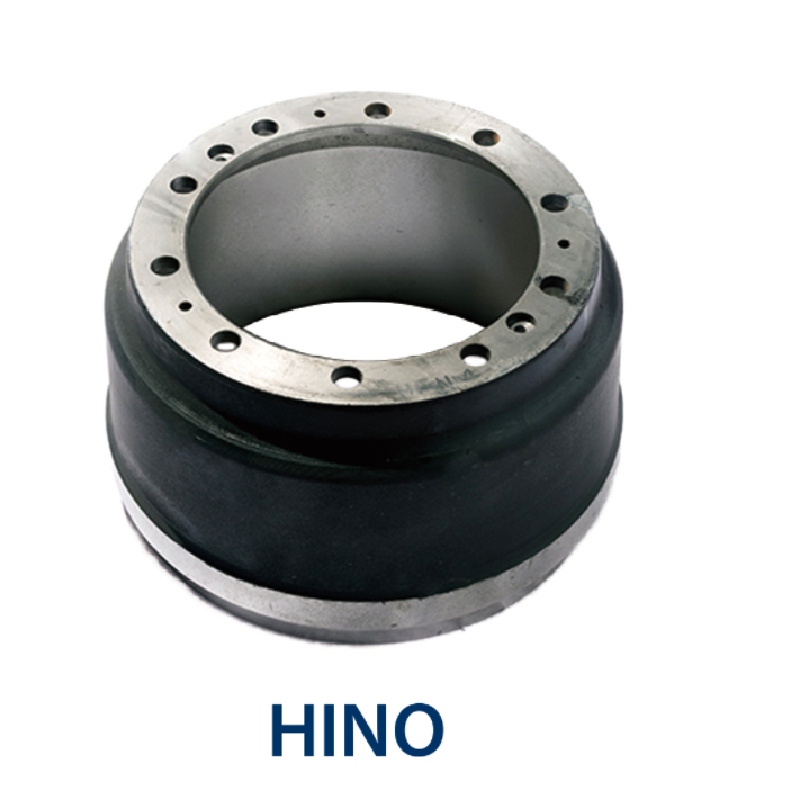

coated brake drums

The Importance of Coated Brake Drums in Automotive Engineering

In the world of automotive engineering, safety and performance are paramount. One often overlooked component that plays a significant role in both areas is the brake drum. Traditionally, brake drums have been made from cast iron, which, while sturdy, can have a range of issues related to corrosion, wear, and heat dissipation. To address these challenges, manufacturers have increasingly turned to coated brake drums, which offer a host of benefits that improve both the lifespan and functionality of braking systems.

Coated brake drums are typically manufactured with a surface layer that protects the underlying material from various environmental factors. This coating can be composed of materials such as ceramic, polymer, or other advanced composites, which provide substantial advantages over traditional materials. One of the primary benefits of using coated brake drums is enhanced corrosion resistance. In damp or corrosive environments, traditional iron drums can rust, leading to compromised braking performance and potentially hazardous situations. Coating the brake drum helps to prevent not only rust but also the degradation that comes with exposure to road salts and other corrosive agents.

Another significant advantage of coated brake drums is improved thermal management. During braking, friction generates heat, which can lead to brake fade—a condition where brakes lose their effectiveness due to overheating. Coatings with high thermal conductivity can help dissipate this heat more efficiently than standard materials, maintaining optimal braking performance even under strenuous conditions. This property is particularly essential for heavy-duty vehicles and those frequently subjected to high-stress braking, such as trucks, buses, and emergency response vehicles.

coated brake drums

Moreover, the friction coefficient of coated brake drums can be optimized through various formulations of the coating material. Enhanced friction equals improved stopping power, which translates to safer driving experiences. Additionally, these coatings can significantly reduce the amount of brake dust generated during normal operations, leading to cleaner wheels and less environmental impact. This reduction in brake dust can also lead to lower maintenance costs for vehicle owners, as they may not need to clean their wheels as often or replace brakes due to excessive wear caused by dust accumulation.

From a manufacturing perspective, the application of coatings to brake drums can lead to improved production techniques. Advanced coating technologies often allow for more uniform application and can be applied in a way that makes them more resilient to wear, thus prolonging the component's lifespan. This durability translates into economics for vehicle manufacturers and consumers alike, as coated brake drums can reduce the frequency of replacements and repairs.

Finally, the trend toward coated brake drums aligns with broader environmental sustainability goals. As emissions regulations become stricter and the automotive industry aims to reduce its carbon footprint, coated brake systems represent a step toward greener technology. By improving efficiency and longevity, these components help to decrease waste and resource consumption in vehicle manufacturing and maintenance.

In conclusion, coated brake drums are a critical advancement in automotive technology that enhance performance, increase safety, and contribute to environmental sustainability. As the automotive landscape continues to evolve, it is clear that innovations such as these will play a vital role in shaping the future of vehicle design and functionality. As consumers become more aware of these options, the demand for coated brake drums is likely to increase, driving further advancements and fostering a safer driving experience for all.

-

Your Brake Drum Man: Premium & Reliable Brake Drums for Sale

NewsAug.18,2025

-

ROR Web Development: Build Fast, Scalable, Secure Apps

NewsAug.17,2025

-

Scania Brake Drums: OEM Quality for Optimal Safety & Durability

NewsAug.16,2025

-

R.V.I: Advanced Remote Visual Inspection for Precision

NewsAug.15,2025

-

Discover HYUNDA: Innovative Vehicles, Equipment & Solutions

NewsAug.14,2025

-

R.V.I: Unlock Advanced Insights & Real-time Performance

NewsAug.13,2025