Nov . 25, 2024 23:08 Back to list

Understanding Commercial Brake Drums and Their Importance in Vehicle Safety and Performance

Understanding Commercial Brake Drums Importance, Functionality, and Maintenance

When it comes to heavy-duty vehicles, safety and reliability are paramount. Among the critical components ensuring safety on the road are brake systems, and at the heart of these systems often lie the brake drums. This article delves into the essential aspects of commercial brake drums, including their design, functionality, and maintenance, highlighting their importance in various vehicles.

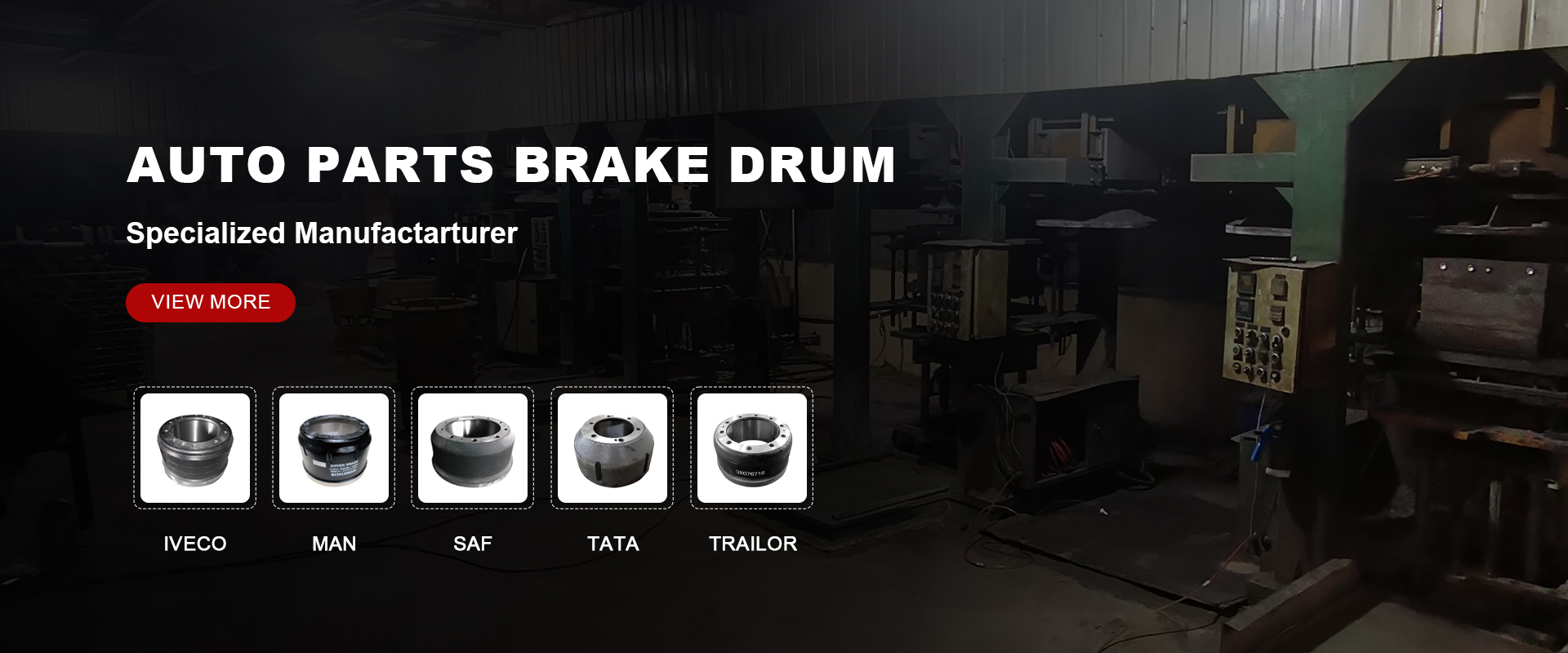

What are Commercial Brake Drums?

Brake drums are cylindrical components that are crucial in the drum brake system, a common type of braking mechanism used in heavy-duty vehicles, such as trucks and buses. In essence, brake drums are responsible for housing the brake shoes and facilitating the accumulation of friction that ultimately brings the vehicle to a halt. When the driver applies the brakes, hydraulic force pushes the brake shoes against the inner surface of the drum, creating friction that stops the vehicle.

Importance of Brake Drums in Commercial Vehicles

1. Safety Brake drums play a vital role in the safety of commercial vehicles. Given that these vehicles often carry heavy loads and travel long distances, efficient braking is essential to prevent accidents. The quality and performance of brake drums directly impact the stopping distance and overall safety of the vehicle.

2. Durability Made from robust materials like cast iron or aluminum alloy, commercial brake drums are designed to withstand high temperatures and wear. Their resilience ensures that they can handle the rigors of frequent stops and the stress of heavy payloads, making them ideal for commercial applications.

3. Cost-effectiveness Utilizing brake drums can be more cost-effective for fleet operators compared to disc brakes. While disc brake systems may offer enhanced performance, brake drums typically incur lower replacement costs and require less frequent servicing under normal conditions.

Functionality of Brake Drums

The operational principle of brake drums is relatively straightforward. When the brake pedal is pressed, the hydraulic system activates the brake shoes, pressing them outward against the interior surface of the drum. This contact creates friction, which converts kinetic energy into thermal energy, effectively slowing down or stopping the vehicle.

commercial brake drums

An essential feature of brake drums is their ability to disperse heat. As friction generates heat, the drum must efficiently dissipate this heat to prevent deformation or failure. In heavy-duty applications, the drum’s design incorporates features such as venting holes to enhance airflow and cooling, thus maintaining optimal performance.

Maintenance of Brake Drums

Proper maintenance of brake drums is crucial in ensuring their longevity and reliable performance. Fleet operators should adhere to the following routines

1. Regular Inspections Routine inspections of brake drums are essential. Technicians should check for signs of wear, including cracks, grooves, or excessive heating. If the brake drum shows significant wear, it may need to be replaced to maintain effective braking performance.

2. Brake Shoe Replacement Brake shoes should be regularly checked and replaced when worn down. As the shoes wear, they can cause uneven wear on the drum, leading to reduced efficiency and potential failure.

3. Cleaning and Adjustment Dust and debris can accumulate in the drum area over time, which may hinder performance. Regular cleaning can help maintain optimal braking efficiency. Additionally, ensuring that the brakes are properly adjusted will maximize the contact area between the shoes and drums, enhancing braking effectiveness.

4. Heat Management As mentioned, brake drums are subjected to significant heat during operation. Using high-quality materials and ensuring adequate cooling can prevent long-term damage. Operators should be mindful of the drum temperature during intense braking situations to avoid thermal failure.

Conclusion

Commercial brake drums are a pivotal component in the braking systems of heavy-duty vehicles, contributing significantly to safety and reliability on the road. Understanding their functionality, importance, and maintenance can help fleet operators and vehicle owners ensure their vehicles operate safely and efficiently. Regular inspections and proper care will not only prolong the life of brake drums but also contribute to the overall safety of all road users.

-

Scania Brake Drums: OEM Quality for Optimal Safety & Durability

NewsAug.16,2025

-

R.V.I: Advanced Remote Visual Inspection for Precision

NewsAug.15,2025

-

Discover HYUNDA: Innovative Vehicles, Equipment & Solutions

NewsAug.14,2025

-

R.V.I: Unlock Advanced Insights & Real-time Performance

NewsAug.13,2025

-

Kamaz Brake Drum: Durable & Reliable for Heavy Duty Trucks

NewsAug.12,2025

-

Heavy Duty Iveco Brake Drum - Premium Quality & Safety

NewsAug.11,2025