Oct . 05, 2024 03:02 Back to list

Exploring the Features and Benefits of Commercial Brake Drums for Heavy-Duty Vehicles

Understanding Commercial Brake Drums Importance and Functionality

In the realm of transportation and heavy vehicles, safety and efficiency are paramount. One of the crucial components that contribute to these ideals is the commercial brake drum. Brake drums are an essential part of the braking system, particularly in large trucks, buses, and trailers, where they play a significant role in ensuring smooth and reliable stopping power.

A brake drum is a cylindrical component that rotates with the wheel and works in conjunction with the brake shoes. When the driver presses the brake pedal, hydraulic pressure pushes the brake shoes outward against the inner surface of the drum. This friction generates the necessary force to slow down or stop the vehicle. The effectiveness of this system lies in the material and design of the brake drum, which is typically made from cast iron or steel for enhanced durability and heat resistance.

One of the key characteristics of commercial brake drums is their ability to dissipate heat. During heavy braking, especially under load, the temperature of the drum can rise significantly. If the drums can’t effectively manage this heat, it may lead to brake fade, where the braking power diminishes, causing dangerously long stopping distances. To combat this, many modern brake drums are designed with ventilation features or constructed using composite materials that can withstand higher temperatures without compromising structural integrity.

commercial brake drums

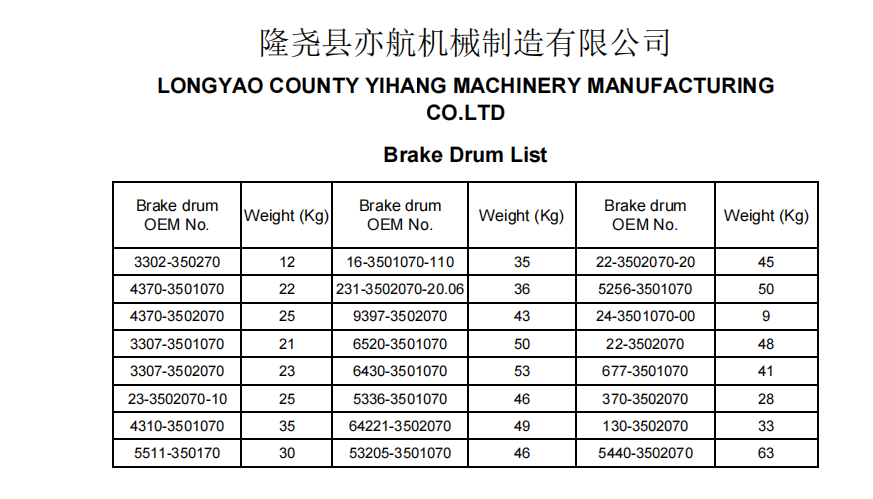

Another important factor in the performance of brake drums is their size. Larger drums can provide more surface area for brake shoes to make contact, resulting in increased friction and, consequently, more stopping power. This is particularly vital for commercial vehicles that carry heavy loads, as they require robust braking systems to manage the dynamics involved. Manufacturers often provide various sizes and specifications, allowing fleets to choose the appropriate drum to match their vehicle's needs.

Maintenance is another critical aspect of commercial brake drums. Regular inspections can help identify wear and tear, such as cracks, warping, or excessive scoring of the drum surface. It is recommended to replace brake drums in conjunction with brake shoes to ensure optimal performance. Ignoring signs of wear can jeopardize not only the vehicle's stopping ability but also the safety of its occupants and other road users.

In recent years, there has been a push towards incorporating advanced materials and technologies in the manufacturing of brake drums. Innovations such as lighter composite materials aim to improve fuel efficiency while maintaining high standards of safety. Moreover, the introduction of smart technologies, like sensors that monitor the condition of brake components in real time, is paving the way for safer and more reliable braking systems.

In conclusion, commercial brake drums are vital components that ensure the safety and efficiency of heavy vehicles. Their design, material composition, and maintenance are fundamental aspects that dictate their performance. As the transportation industry continues to evolve, ongoing innovations in brake drum technology will play an essential role in enhancing vehicle safety and reliability, thus safeguarding lives on the road.

-

Scania Brake Drums: OEM Quality for Optimal Safety & Durability

NewsAug.16,2025

-

R.V.I: Advanced Remote Visual Inspection for Precision

NewsAug.15,2025

-

Discover HYUNDA: Innovative Vehicles, Equipment & Solutions

NewsAug.14,2025

-

R.V.I: Unlock Advanced Insights & Real-time Performance

NewsAug.13,2025

-

Kamaz Brake Drum: Durable & Reliable for Heavy Duty Trucks

NewsAug.12,2025

-

Heavy Duty Iveco Brake Drum - Premium Quality & Safety

NewsAug.11,2025