Dec . 23, 2024 12:31 Back to list

Understanding the Importance of Brake Drums in Commercial Truck Safety and Performance

Understanding Commercial Truck Brake Drums Importance and Maintenance

Brake systems are paramount when it comes to ensuring the safety and reliability of commercial trucks. Among the various components that contribute to a truck's braking system, brake drums play a crucial role. This article will delve into the function, significance, and maintenance of commercial truck brake drums, providing insights for fleet owners and operators.

What Are Brake Drums?

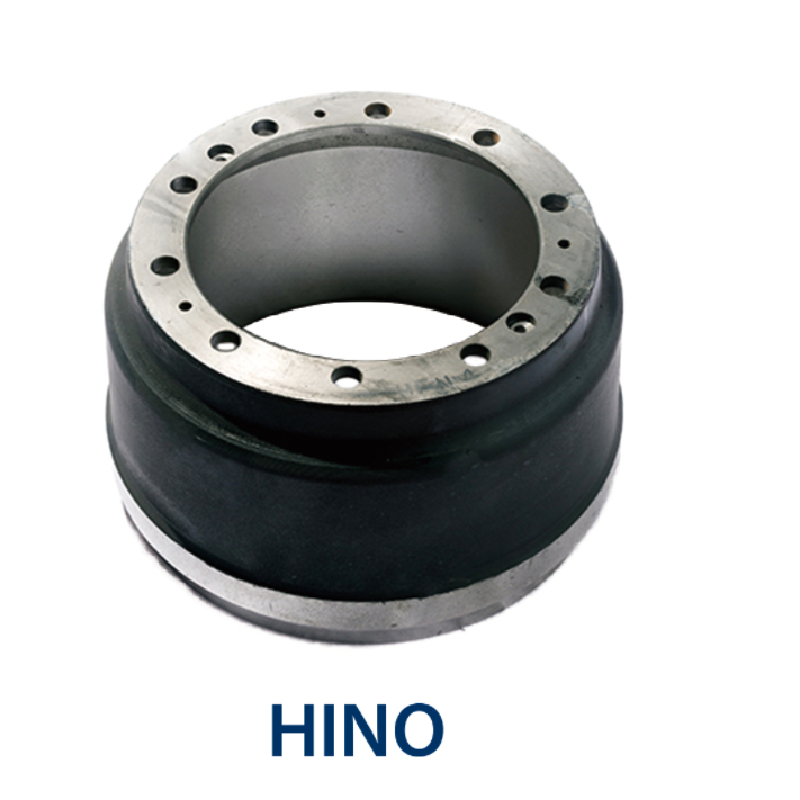

Brake drums are part of a drum brake system, which is one of the oldest types of braking systems in vehicles. When the brake pedal is pressed, brake shoes are forced against the inner surface of the drum, creating friction that slows down and stops the vehicle. This friction is generated through the contact between the brake shoes, which are lined with a friction material, and the brake drum, which is attached to the wheel hub.

The Importance of Brake Drums

1. Safety The primary function of brake drums is to safely decelerate the vehicle. In commercial trucks, which often carry heavy loads, effective braking is critical. Any failure in the braking system can lead to catastrophic accidents, making it essential that brake drums are in good condition.

2. Durability Brake drums made from durable materials can withstand the considerable heat generated during braking. High-quality materials maintain structural integrity, ensuring that the drum does not warp or crack under pressure. This is particularly vital for trucks operating under severe conditions, such as heavy hauling or continuous stop-and-go traffic.

3. Cost-Effectiveness Maintaining brake drums is often more economical than replacing them. Regular inspections can identify problems early, reducing the likelihood of catastrophic failure that could lead to more extensive repairs and downtime.

Signs of Worn or Damaged Brake Drums

Recognizing when brake drums need inspection or replacement is crucial

. Some signs of wear or damage includecommercial truck brake drums

- Vibration or Pulsation If the brake pedal pulsates when pressed, this may indicate that the drum is warped or unevenly worn. - Unusual Sounds Grinding or screeching noises during braking can signal that the brake lining has worn down, causing the shoes to make contact with the drum's metal surface. - Increased Stopping Distance If a truck takes longer to stop than usual, it might indicate that the brake drums need attention.

Maintenance of Brake Drums

Proper maintenance can significantly extend the lifespan of brake drums and ensure optimal performance. Here are some best practices

1. Regular Inspections Scheduled inspections should be conducted to check for wear, cracks, and other damage. Fleet managers should implement a routine maintenance schedule to ensure that brake components, including drums, are evaluated regularly.

2. Cleaning Dust and debris can accumulate within the brake drum area, affecting performance. Cleaning the drums and surrounding components as part of routine maintenance helps ensure smooth operation.

3. Monitor Brake Pad Wear The health of the brake pads directly affects the condition of the drum. Regularly replacing worn pads prevents excessive wear on the drum surface.

4. Professional Servicing While some maintenance tasks can be performed in-house, many require professional service. Brake systems are intricate, and certified mechanics should handle any repairs or replacements to ensure safety and compliance with industry standards.

Conclusion

In summary, commercial truck brake drums are an essential component of the braking system, directly impacting the safety and efficiency of heavy-duty vehicles. Understanding their function, recognizing signs of wear, and adhering to a regular maintenance schedule are vital steps for fleet owners and operators to ensure their vehicles operate safely and economically on the road. By prioritizing maintenance and being proactive about inspections, the lifespan of brake drums can be extended, resulting in improved safety and overall operational efficiency.

-

Volvo Brake Drum: OEM Quality, Optimal Safety

NewsAug.27,2025

-

Durable Brake Drum MAZ for Heavy Duty Trucks | High Performance

NewsAug.26,2025

-

FUWA: Premium Quality, Reliable Performance & Innovative Solutions

NewsAug.25,2025

-

Liza Brake Drum: Superior Quality & Performance for Safe Driving

NewsAug.24,2025

-

Iveco Brake Drum | Premium OE Quality for Daily & Eurocargo

NewsAug.22,2025

-

Your Brake Drum Man: Quality & Performance Parts

NewsAug.21,2025