Jun . 27, 2024 08:05 Back to list

Determining the Ideal Size for Semi-Truck Brake Drums A Comprehensive Guide

Understanding Semi-Truck Brake Drum Sizes A Comprehensive Guide

In the world of commercial transportation, safety is paramount, and one critical component that ensures this is the braking system. A semi-truck, also known as a tractor-trailer, carries immense weight and requires powerful brakes to bring it to a halt safely. The brake drum, an essential part of this system, plays a vital role in decelerating and stopping these massive vehicles. This article will delve into the details of semi-truck brake drum sizes and their significance.

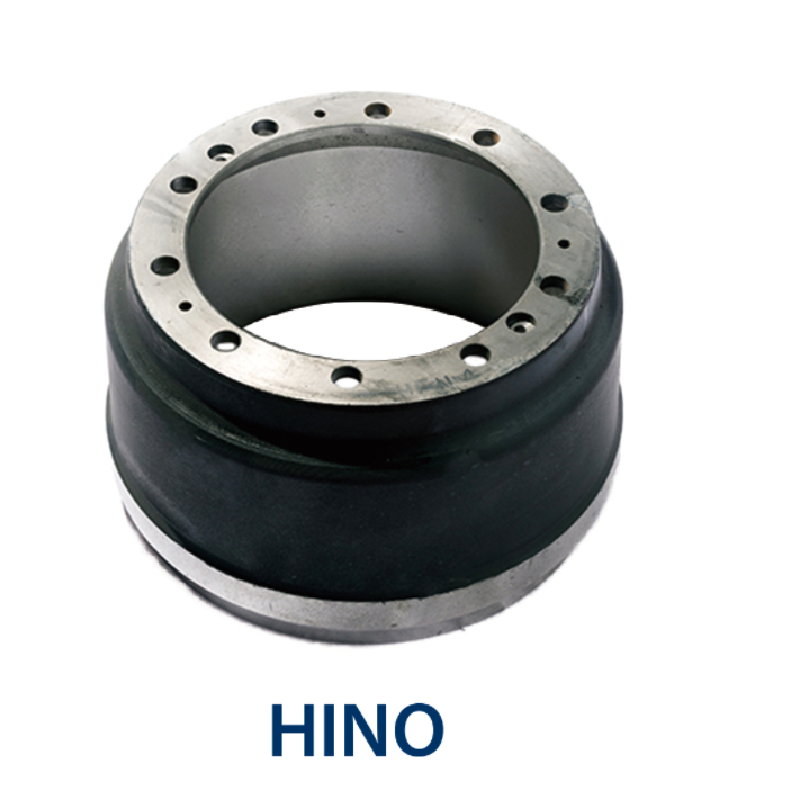

A brake drum, essentially a hollow cylinder, houses the brake shoes or pads that press against the inner surface when the brakes are applied, generating friction and slowing down the vehicle. In a semi-truck, the brake drums are larger due to the increased stopping power required. Typically, they range from 16 to 24 inches in diameter, with some even reaching 28 inches for heavy-duty applications. The size directly correlates with the vehicle's weight capacity and the force needed to slow down or stop it efficiently.

The size selection is not arbitrary but is based on various factors. First and foremost, the Gross Vehicle Weight Rating (GVWR) of the truck determines the drum size. The GVWR is the maximum operating weight specified by the manufacturer, including the vehicle, passengers, and cargo. Heavier loads necessitate larger drums to provide the necessary friction surface area.

Moreover, the brake drum's material and construction also influence its effectiveness. Generally made from cast iron, these drums must withstand high temperatures and mechanical stress Generally made from cast iron, these drums must withstand high temperatures and mechanical stress Generally made from cast iron, these drums must withstand high temperatures and mechanical stress Generally made from cast iron, these drums must withstand high temperatures and mechanical stress

Generally made from cast iron, these drums must withstand high temperatures and mechanical stress Generally made from cast iron, these drums must withstand high temperatures and mechanical stress semi truck brake drum size. Larger drums can dissipate heat more effectively, reducing the risk of brake fade - a condition where brakes lose effectiveness due to excessive heat.

Another factor to consider is the drum's ability to accommodate the brake lining wear. As the lining wears down, the brake shoes need to maintain contact with the drum's entire surface. Larger drums ensure a wider contact area even with worn linings, maintaining consistent braking performance.

Regular maintenance and inspection are crucial for semi-truck brake drums. Over time, drums can warp or crack, compromising their performance. Regular inspections help identify such issues early, allowing for timely repairs or replacements.

In conclusion, the semi-truck brake drum size is a critical determinant of the vehicle's safety and operational efficiency. It's a balance between providing adequate stopping power, managing heat dissipation, and accommodating wear. Understanding these aspects is vital for fleet managers, mechanics, and drivers alike, ensuring that these giants of the road can be safely maneuvered in all conditions. Remember, bigger isn't always better; it's about finding the right fit for the job at hand.

semi truck brake drum size. Larger drums can dissipate heat more effectively, reducing the risk of brake fade - a condition where brakes lose effectiveness due to excessive heat.

Another factor to consider is the drum's ability to accommodate the brake lining wear. As the lining wears down, the brake shoes need to maintain contact with the drum's entire surface. Larger drums ensure a wider contact area even with worn linings, maintaining consistent braking performance.

Regular maintenance and inspection are crucial for semi-truck brake drums. Over time, drums can warp or crack, compromising their performance. Regular inspections help identify such issues early, allowing for timely repairs or replacements.

In conclusion, the semi-truck brake drum size is a critical determinant of the vehicle's safety and operational efficiency. It's a balance between providing adequate stopping power, managing heat dissipation, and accommodating wear. Understanding these aspects is vital for fleet managers, mechanics, and drivers alike, ensuring that these giants of the road can be safely maneuvered in all conditions. Remember, bigger isn't always better; it's about finding the right fit for the job at hand.

Generally made from cast iron, these drums must withstand high temperatures and mechanical stress Generally made from cast iron, these drums must withstand high temperatures and mechanical stress

Generally made from cast iron, these drums must withstand high temperatures and mechanical stress Generally made from cast iron, these drums must withstand high temperatures and mechanical stress semi truck brake drum size. Larger drums can dissipate heat more effectively, reducing the risk of brake fade - a condition where brakes lose effectiveness due to excessive heat.

Another factor to consider is the drum's ability to accommodate the brake lining wear. As the lining wears down, the brake shoes need to maintain contact with the drum's entire surface. Larger drums ensure a wider contact area even with worn linings, maintaining consistent braking performance.

Regular maintenance and inspection are crucial for semi-truck brake drums. Over time, drums can warp or crack, compromising their performance. Regular inspections help identify such issues early, allowing for timely repairs or replacements.

In conclusion, the semi-truck brake drum size is a critical determinant of the vehicle's safety and operational efficiency. It's a balance between providing adequate stopping power, managing heat dissipation, and accommodating wear. Understanding these aspects is vital for fleet managers, mechanics, and drivers alike, ensuring that these giants of the road can be safely maneuvered in all conditions. Remember, bigger isn't always better; it's about finding the right fit for the job at hand.

semi truck brake drum size. Larger drums can dissipate heat more effectively, reducing the risk of brake fade - a condition where brakes lose effectiveness due to excessive heat.

Another factor to consider is the drum's ability to accommodate the brake lining wear. As the lining wears down, the brake shoes need to maintain contact with the drum's entire surface. Larger drums ensure a wider contact area even with worn linings, maintaining consistent braking performance.

Regular maintenance and inspection are crucial for semi-truck brake drums. Over time, drums can warp or crack, compromising their performance. Regular inspections help identify such issues early, allowing for timely repairs or replacements.

In conclusion, the semi-truck brake drum size is a critical determinant of the vehicle's safety and operational efficiency. It's a balance between providing adequate stopping power, managing heat dissipation, and accommodating wear. Understanding these aspects is vital for fleet managers, mechanics, and drivers alike, ensuring that these giants of the road can be safely maneuvered in all conditions. Remember, bigger isn't always better; it's about finding the right fit for the job at hand. Latest news

-

ROR Web Development: Build Fast, Scalable, Secure Apps

NewsAug.17,2025

-

Scania Brake Drums: OEM Quality for Optimal Safety & Durability

NewsAug.16,2025

-

R.V.I: Advanced Remote Visual Inspection for Precision

NewsAug.15,2025

-

Discover HYUNDA: Innovative Vehicles, Equipment & Solutions

NewsAug.14,2025

-

R.V.I: Unlock Advanced Insights & Real-time Performance

NewsAug.13,2025

-

Kamaz Brake Drum: Durable & Reliable for Heavy Duty Trucks

NewsAug.12,2025