Jan . 31, 2025 05:58 Back to list

Webb Drums

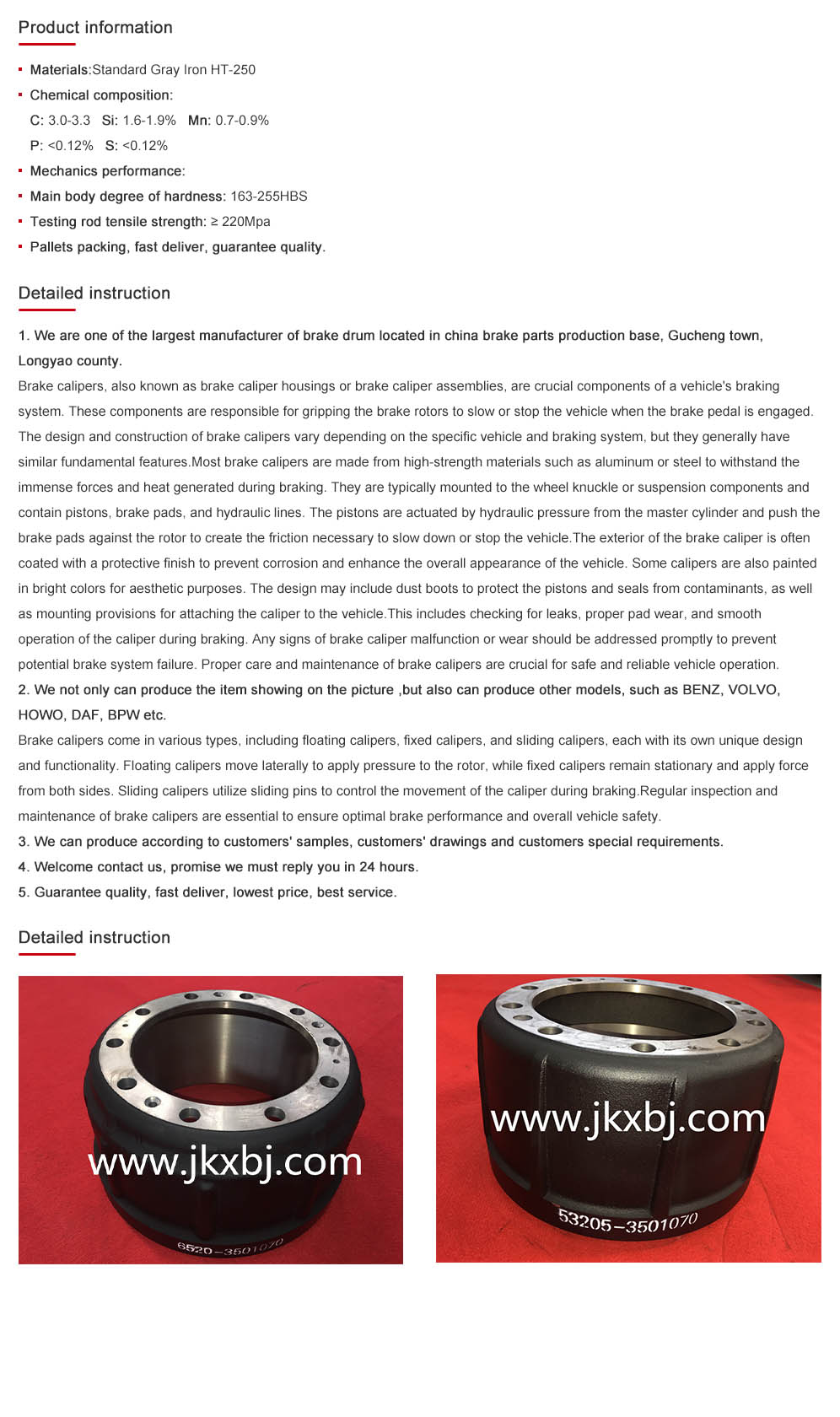

Understanding the intricate components of a brake drum system is crucial for any vehicle enthusiast or industry professional tasked with ensuring optimal vehicle performance and safety. The key to mastering this component lies in grasping its structure, functionality, and maintenance practices, ensuring it remains in peak condition while enhancing your credibility as an automotive expert.

For industry professionals and vehicle owners alike, understanding the limits and performance metrics of brake drums is vital. Heat dissipation is a major concern, as excessive heat can lead to brake fade – a temporary loss of braking power. Ensuring that drums are neither too thin from wear nor cracked from excessive heat is fundamental to vehicle safety. Incorporating a conceptual diagram can greatly enhance comprehension. Such a diagram provides a visual representation of how all components interrelate within the brake drum system. It depicts the arrangement of the brake shoes, the positioning of the hydraulic cylinder, and shows the forces at play during braking. To elevate your expertise further, staying abreast of innovations in brake drum technology is advisable. Advances in materials, such as composite drums, offer improved heat management and durability. Furthermore, innovations in friction material for brake shoes contribute to enhanced performance and longevity, addressing many historical pain points associated with traditional drum brakes. Ultimately, positioning yourself as an authoritative figure on brake drums requires a blend of theoretical knowledge and practical experience. Engaging in continued learning, leveraging high-quality, up-to-date technical diagrams, and adhering to rigorous maintenance standards ensures not only the brake system's reliability but also an enhancement of your professional reputation in the automotive field. This in-depth understanding of brake drums not only reinforces safety but also enhances vehicle performance, providing peace of mind to vehicle owners and professionals responsible for their upkeep.

For industry professionals and vehicle owners alike, understanding the limits and performance metrics of brake drums is vital. Heat dissipation is a major concern, as excessive heat can lead to brake fade – a temporary loss of braking power. Ensuring that drums are neither too thin from wear nor cracked from excessive heat is fundamental to vehicle safety. Incorporating a conceptual diagram can greatly enhance comprehension. Such a diagram provides a visual representation of how all components interrelate within the brake drum system. It depicts the arrangement of the brake shoes, the positioning of the hydraulic cylinder, and shows the forces at play during braking. To elevate your expertise further, staying abreast of innovations in brake drum technology is advisable. Advances in materials, such as composite drums, offer improved heat management and durability. Furthermore, innovations in friction material for brake shoes contribute to enhanced performance and longevity, addressing many historical pain points associated with traditional drum brakes. Ultimately, positioning yourself as an authoritative figure on brake drums requires a blend of theoretical knowledge and practical experience. Engaging in continued learning, leveraging high-quality, up-to-date technical diagrams, and adhering to rigorous maintenance standards ensures not only the brake system's reliability but also an enhancement of your professional reputation in the automotive field. This in-depth understanding of brake drums not only reinforces safety but also enhances vehicle performance, providing peace of mind to vehicle owners and professionals responsible for their upkeep.

Next:

Latest news

-

Scania Brake Drums: OEM Quality for Optimal Safety & Durability

NewsAug.16,2025

-

R.V.I: Advanced Remote Visual Inspection for Precision

NewsAug.15,2025

-

Discover HYUNDA: Innovative Vehicles, Equipment & Solutions

NewsAug.14,2025

-

R.V.I: Unlock Advanced Insights & Real-time Performance

NewsAug.13,2025

-

Kamaz Brake Drum: Durable & Reliable for Heavy Duty Trucks

NewsAug.12,2025

-

Heavy Duty Iveco Brake Drum - Premium Quality & Safety

NewsAug.11,2025