Jul . 29, 2024 22:31 Back to list

Exploring the Mechanics and Performance of Turn Brake Drums in Modern Vehicles

Understanding Turn Brake Drums A Critical Component of Vehicle Safety

In the realm of automotive engineering, the intricacies of vehicle braking systems are fundamental to ensuring safety and performance. One such critical element within these systems is the brake drum, particularly the turn brake drums used in various applications. Understanding how turn brake drums function and their significance can illuminate the crucial role they play in vehicle safety and efficiency.

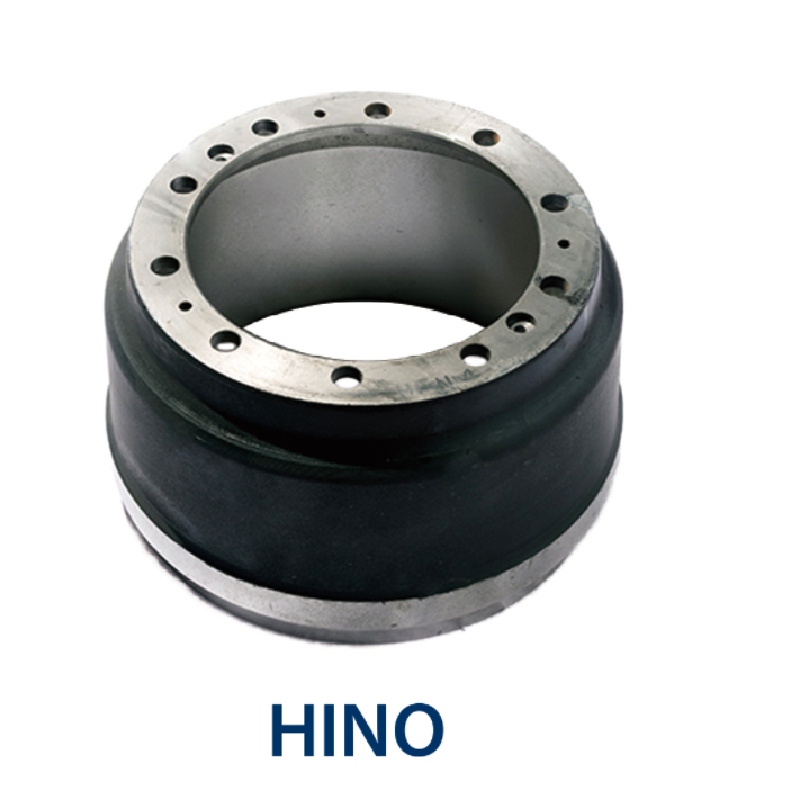

A brake drum is a cylindrical component that rotates along with the wheel of a vehicle. It is part of a drum brake system, which employs friction to slow down or stop the motion of the vehicle. In contrast to disc brakes, where the brake pads clamp onto a flat disc, drum brakes utilize shoes that press against the inner surface of the drum. This design takes advantage of the rotational movement, allowing for effective braking even under substantial load or stress.

Turn brake drums are specialized variants primarily used in applications requiring enhanced braking performance during turning maneuvers. This is particularly relevant in vehicles like trucks, buses, and certain industrial machinery, where stability and control are paramount. The engineering behind turn brake drums allows them to manage not just the linear deceleration of a vehicle, but also the lateral forces experienced during turns.

One of the significant advantages of turn brake drums is their ability to provide a larger surface area for braking compared to disc brakes. This can lead to improved heat dissipation and reduced brake fade, which is the reduction in stopping power due to overheating. The construction of turn brake drums often involves materials that can withstand high temperatures and resist wear, ensuring long-term reliability and performance.

turn brake drums

However, like all components of a vehicle, turn brake drums require regular maintenance to function optimally. Over time, they may become warped due to excessive heat or wear and tear, leading to reduced braking efficiency. Common signs of issues with brake drums include a pulsating brake pedal, noises during braking, or uneven brake wear. Routine inspections and timely replacements are essential to maintain the effectiveness of the braking system.

In many cases, the selection of the right turn brake drum goes beyond just size and material; it involves considering the specific needs of the vehicle and its intended use. For example, heavier vehicles that often carry substantial loads require more robust brake drums to ensure safe stopping distances. Additionally, advances in technology have led to the development of lightweight materials that do not compromise strength, thereby enhancing overall vehicle performance.

Furthermore, regulatory standards mandate that manufacturers adhere to stringent guidelines regarding the performance and safety of braking systems. As a result, the industry continuously innovates to enhance the designs and materials used in turn brake drums. This evolution is crucial, especially with the rise of electric and autonomous vehicles, which may employ different braking technologies.

In conclusion, turn brake drums are a vital component of vehicle braking systems, playing an essential role in ensuring safety during both straight-line and turning maneuvers. Their effective design, coupled with the need for regular maintenance, illustrates the delicate balance between engineering excellence and operational reliability. As automotive technologies advance, the continued focus on improving braking systems, including turn brake drums, remains paramount. This will not only enhance vehicle performance but ultimately contribute to safer roads for all.

-

Explore Japan: Ultimate Travel Guide & Authentic Experiences

NewsAug.19,2025

-

Your Brake Drum Man: Premium & Reliable Brake Drums for Sale

NewsAug.18,2025

-

ROR Web Development: Build Fast, Scalable, Secure Apps

NewsAug.17,2025

-

Scania Brake Drums: OEM Quality for Optimal Safety & Durability

NewsAug.16,2025

-

R.V.I: Advanced Remote Visual Inspection for Precision

NewsAug.15,2025

-

Discover HYUNDA: Innovative Vehicles, Equipment & Solutions

NewsAug.14,2025