Jun . 28, 2024 12:20 Back to list

Gunite Brake Drum Assembly Uncovering the Cross Reference

The Intersection of Gunite, Brake Drums, and Cross Innovation

In the world of automotive engineering, the fusion of diverse materials and technologies often leads to groundbreaking innovations. One such intriguing intersection lies at the crossroads of gunite, brake drums, and cross design principles. This unique blend not only pushes the boundaries of conventional thinking but also redefines the performance and durability standards in the automotive industry.

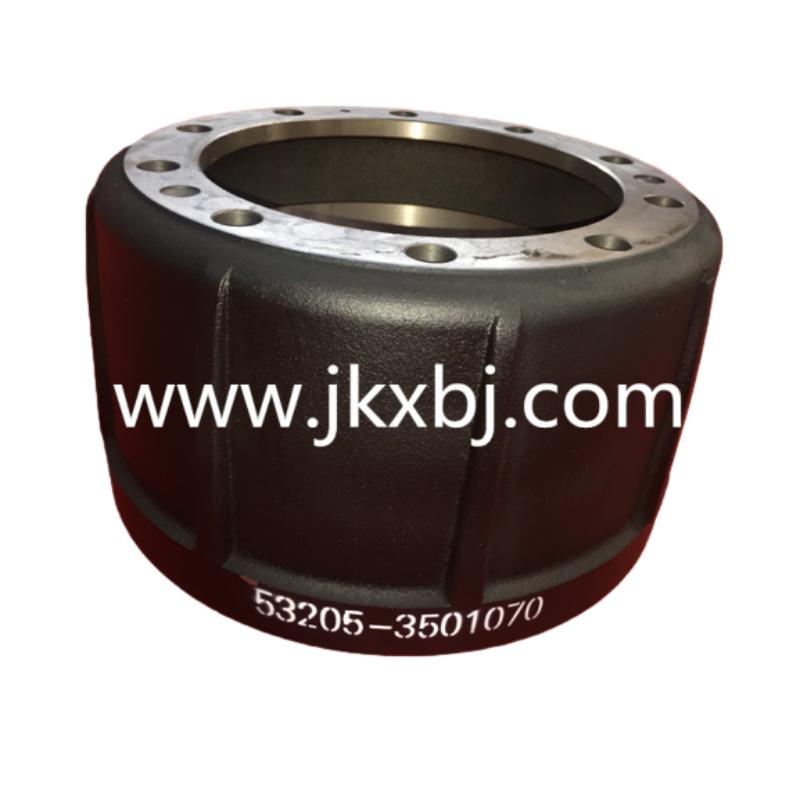

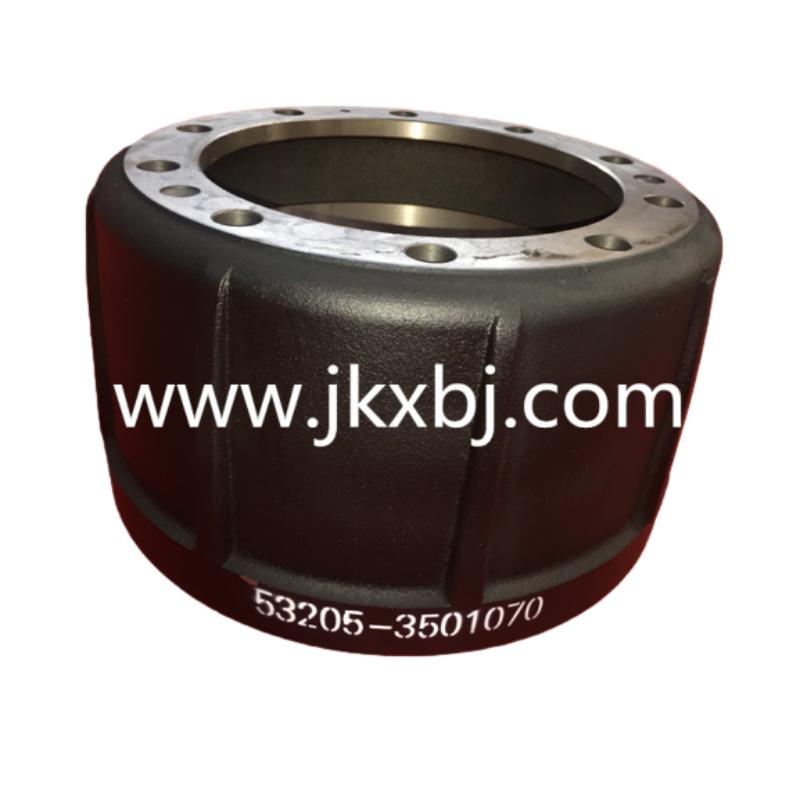

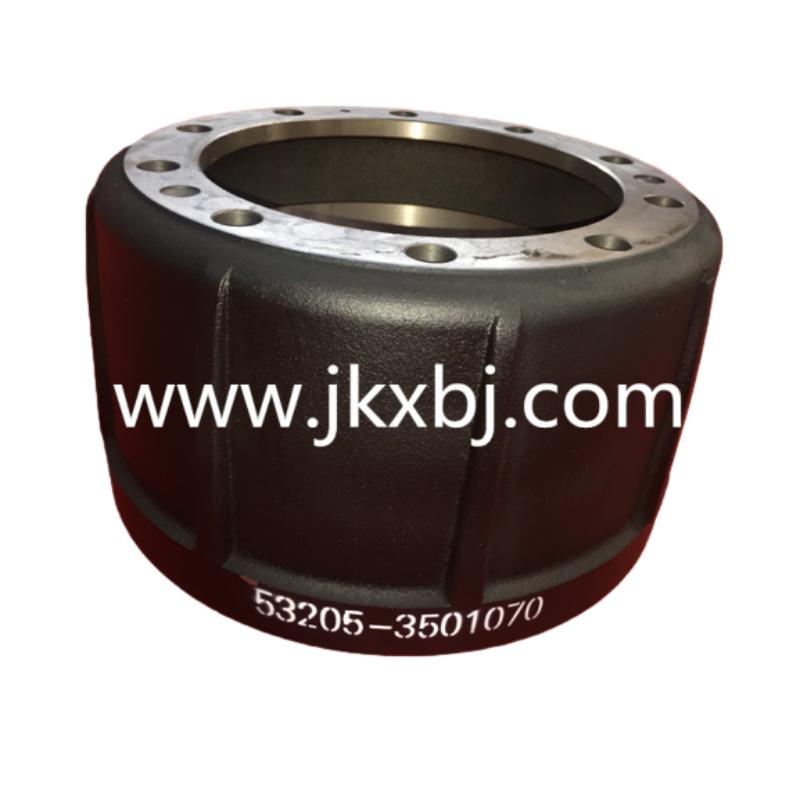

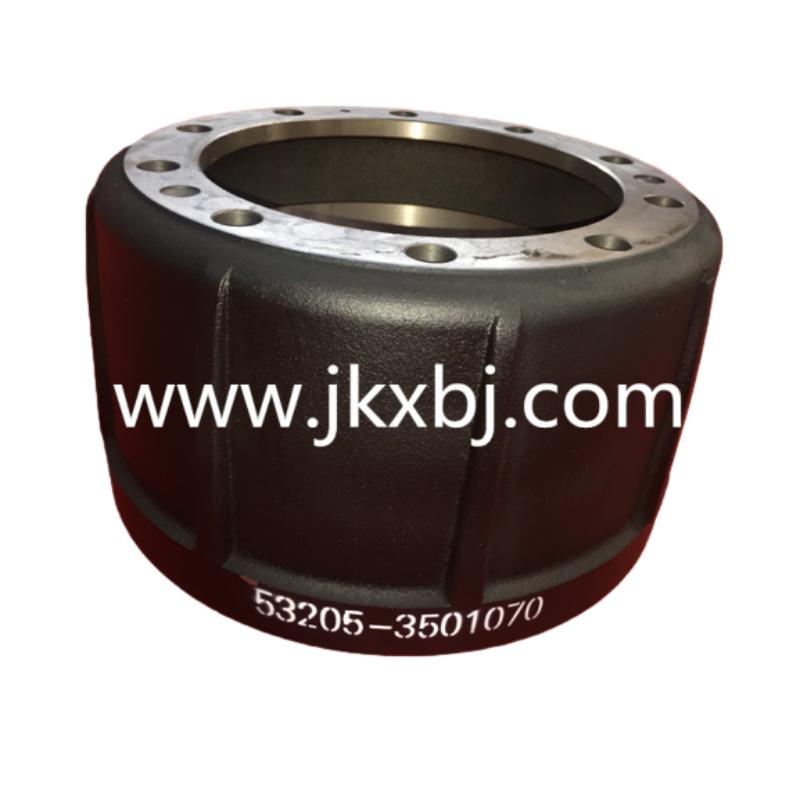

Gunite, a process originally developed for concrete construction, involves shooting a mixture of cement and aggregate through a hose with compressed air, creating a hard, durable surface. Its application has expanded beyond its original purpose, finding its way into the manufacturing of brake drums due to its inherent strength and resistance to wear. Brake drums, integral components in the braking system of vehicles, are responsible for converting kinetic energy into heat when brakes are applied, necessitating robust materials that can withstand high temperatures and friction.

The introduction of gunite in brake drum production has resulted in a significant improvement in the durability and heat dissipation capabilities. The gunite coating, with its dense and uniform structure, enhances the drum's ability to resist cracking and distortion under intense heat, thus ensuring consistent and reliable braking performance over time.

Furthermore, the concept of cross design comes into play here, referring to the integration of multiple disciplines or technologies to create a more efficient and optimized product

Furthermore, the concept of cross design comes into play here, referring to the integration of multiple disciplines or technologies to create a more efficient and optimized product Furthermore, the concept of cross design comes into play here, referring to the integration of multiple disciplines or technologies to create a more efficient and optimized product

Furthermore, the concept of cross design comes into play here, referring to the integration of multiple disciplines or technologies to create a more efficient and optimized product

Furthermore, the concept of cross design comes into play here, referring to the integration of multiple disciplines or technologies to create a more efficient and optimized product

Furthermore, the concept of cross design comes into play here, referring to the integration of multiple disciplines or technologies to create a more efficient and optimized product gunite brake drum cross. In the context of gunite brake drums, this could mean incorporating advanced cooling channels within the drum's cross-section, designed to enhance heat dissipation. These channels, strategically placed, improve the brake drum's thermal efficiency, reducing the risk of brake fade and prolonging the life of the brake lining.

Moreover, the cross design may also involve optimizing the weight distribution of the brake drum, enhancing vehicle stability and fuel efficiency. By using gunite to create a thinner yet stronger drum, engineers can achieve a lighter yet robust component, striking a perfect balance between performance and economy.

In conclusion, the fusion of gunite technology with the traditional brake drum and the principles of cross design exemplifies the relentless pursuit of innovation in the automotive sector. It underscores the importance of interdisciplinary collaboration and the willingness to explore unconventional solutions to age-old problems. As we continue to push the limits of what is possible, the marriage of gunite, brake drums, and cross design opens up new avenues for safer, more efficient, and enduring vehicles, shaping the future of transportation.

gunite brake drum cross. In the context of gunite brake drums, this could mean incorporating advanced cooling channels within the drum's cross-section, designed to enhance heat dissipation. These channels, strategically placed, improve the brake drum's thermal efficiency, reducing the risk of brake fade and prolonging the life of the brake lining.

Moreover, the cross design may also involve optimizing the weight distribution of the brake drum, enhancing vehicle stability and fuel efficiency. By using gunite to create a thinner yet stronger drum, engineers can achieve a lighter yet robust component, striking a perfect balance between performance and economy.

In conclusion, the fusion of gunite technology with the traditional brake drum and the principles of cross design exemplifies the relentless pursuit of innovation in the automotive sector. It underscores the importance of interdisciplinary collaboration and the willingness to explore unconventional solutions to age-old problems. As we continue to push the limits of what is possible, the marriage of gunite, brake drums, and cross design opens up new avenues for safer, more efficient, and enduring vehicles, shaping the future of transportation.

Furthermore, the concept of cross design comes into play here, referring to the integration of multiple disciplines or technologies to create a more efficient and optimized product

Furthermore, the concept of cross design comes into play here, referring to the integration of multiple disciplines or technologies to create a more efficient and optimized product

Furthermore, the concept of cross design comes into play here, referring to the integration of multiple disciplines or technologies to create a more efficient and optimized product

Furthermore, the concept of cross design comes into play here, referring to the integration of multiple disciplines or technologies to create a more efficient and optimized product gunite brake drum cross. In the context of gunite brake drums, this could mean incorporating advanced cooling channels within the drum's cross-section, designed to enhance heat dissipation. These channels, strategically placed, improve the brake drum's thermal efficiency, reducing the risk of brake fade and prolonging the life of the brake lining.

Moreover, the cross design may also involve optimizing the weight distribution of the brake drum, enhancing vehicle stability and fuel efficiency. By using gunite to create a thinner yet stronger drum, engineers can achieve a lighter yet robust component, striking a perfect balance between performance and economy.

In conclusion, the fusion of gunite technology with the traditional brake drum and the principles of cross design exemplifies the relentless pursuit of innovation in the automotive sector. It underscores the importance of interdisciplinary collaboration and the willingness to explore unconventional solutions to age-old problems. As we continue to push the limits of what is possible, the marriage of gunite, brake drums, and cross design opens up new avenues for safer, more efficient, and enduring vehicles, shaping the future of transportation.

gunite brake drum cross. In the context of gunite brake drums, this could mean incorporating advanced cooling channels within the drum's cross-section, designed to enhance heat dissipation. These channels, strategically placed, improve the brake drum's thermal efficiency, reducing the risk of brake fade and prolonging the life of the brake lining.

Moreover, the cross design may also involve optimizing the weight distribution of the brake drum, enhancing vehicle stability and fuel efficiency. By using gunite to create a thinner yet stronger drum, engineers can achieve a lighter yet robust component, striking a perfect balance between performance and economy.

In conclusion, the fusion of gunite technology with the traditional brake drum and the principles of cross design exemplifies the relentless pursuit of innovation in the automotive sector. It underscores the importance of interdisciplinary collaboration and the willingness to explore unconventional solutions to age-old problems. As we continue to push the limits of what is possible, the marriage of gunite, brake drums, and cross design opens up new avenues for safer, more efficient, and enduring vehicles, shaping the future of transportation. Latest news

-

Scania Brake Drums: OEM Quality for Optimal Safety & Durability

NewsAug.16,2025

-

R.V.I: Advanced Remote Visual Inspection for Precision

NewsAug.15,2025

-

Discover HYUNDA: Innovative Vehicles, Equipment & Solutions

NewsAug.14,2025

-

R.V.I: Unlock Advanced Insights & Real-time Performance

NewsAug.13,2025

-

Kamaz Brake Drum: Durable & Reliable for Heavy Duty Trucks

NewsAug.12,2025

-

Heavy Duty Iveco Brake Drum - Premium Quality & Safety

NewsAug.11,2025