Dec . 19, 2024 10:32 Back to list

semi truck brake drums

Understanding Semi Truck Brake Drums A Critical Component for Safety and Performance

When it comes to heavy-duty vehicles, especially semi trucks, safety is paramount. One of the essential components that contribute to both the braking efficiency and overall safety of these massive machines is the brake drum. Understanding the role, function, and maintenance of semi truck brake drums is crucial for fleet managers, truck drivers, and anyone involved in the trucking industry.

What Are Brake Drums?

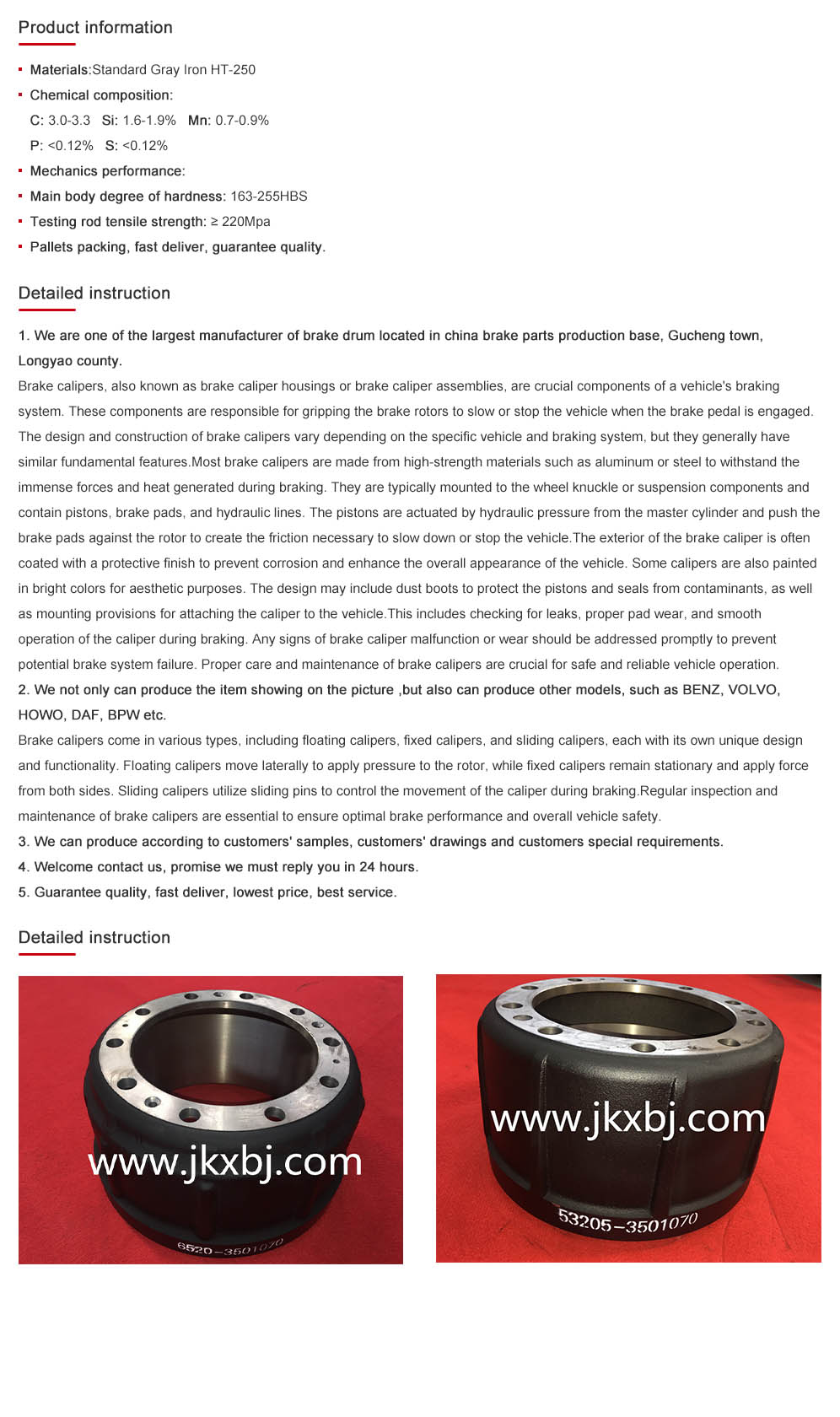

Brake drums are cylindrical components that play a vital role in a vehicle's brake system. They are typically made from cast iron or cast steel, capable of withstanding the high heat generated during braking. When a driver presses the brake pedal, brake shoes within the drum push outward against the inside surface of the drum, creating friction that slows down the vehicle.

Importance of Brake Drums in Semi Trucks

Semi trucks are designed to carry heavy loads, often exceeding several tons. Given their weight, the braking system must be robust and reliable. Brake drums are specifically engineered to handle the intense stress and heat generated during rapid stops. This is particularly important for semi trucks, which travel long distances and encounter various driving conditions, from steep hills to sudden stops in traffic.

One of the key advantages of drum brakes over disc brakes is their ability to dissipate heat effectively. This makes them a favored choice for the rear braking systems in many heavy-duty trucks. Brake drums can withstand wear and tear better under heavy load and provide reliable stopping power when it’s needed most.

Signs of Brake Drum Wear

Keeping an eye on brake drum condition is important for safety and vehicle performance. There are several signs that indicate a semi truck's brake drums may need inspection or replacement. These include

1. Vibration If a driver feels vibrations in the brake pedal or steering wheel, it could indicate uneven wear on the brake drums. 2. Unusual Noises Grinding, squealing, or scraping noises while braking can signal worn-out brake shoes or damaged brake drums.

semi truck brake drums

3. Increased Stopping Distance If the truck takes longer to stop than usual, it could be a warning sign of brake drum failure.

Regular inspections are essential to maintaining brake systems

. Truck operators should closely monitor the condition of their brake drums during routine maintenance checks or before long trips.Maintenance Best Practices

To ensure semi truck brake drums remain in optimal working condition, it’s essential to follow best maintenance practices

- Regular Inspections Conducting thorough inspections of the brake system, including drums, shoes, and other components, can catch issues early.

- Proper Adjustment Brake systems should be properly adjusted to ensure that brake shoes make adequate contact with the drum.

- Replacement of Worn Components Once the brake drums reach their wear limit, they must be replaced to maintain braking efficiency and safety.

- Heat Management After heavy braking, it’s advisable to allow the brake drums to cool down. Overheating can warp the drums, leading to premature failure.

Conclusion

In conclusion, semi truck brake drums are a critical component of a truck’s braking system, ensuring safety and performance in the transport industry. By understanding their function, recognizing signs of wear, and adhering to maintenance best practices, truck operators can significantly enhance their vehicles' safety and reliability. As the trucking industry continues to grow, investing in the knowledge and maintenance of crucial components like brake drums will remain vital in keeping our roads safe for all users.

-

HINO Industrial Solutions - ¡Ң���ຽ��е��������˾ | Advanced Efficiency&Customization

NewsJul.13,2025

-

HINO Industrial Efficiency Solutions - ¡Ң���ຽ��е��������˾

NewsJul.13,2025

-

HINO Industrial Solutions - ¡Ң���ຽ��е��������˾ | Advanced Technology&Reliability

NewsJul.13,2025

-

HINO Industrial Efficiency-Jiangsu Hino Industrial|Productivity Optimization&Cost Reduction

NewsJul.12,2025

-

HINO-¡Ң���ຽ��е��������˾|Advanced Industrial Solutions&Energy Efficiency

NewsJul.12,2025

-

Premium Brake Drum Iveco – Durable Drum Brake Drum & Brake Shoe Solutions

NewsJul.08,2025