Dec . 18, 2024 20:08 Back to list

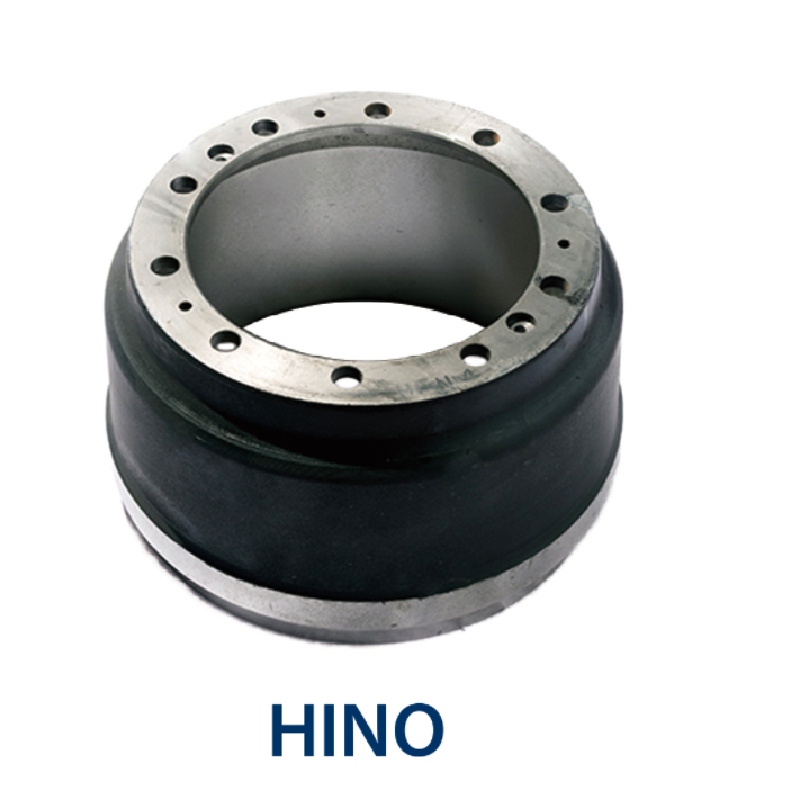

tractor brake drum

Understanding the Tractor Brake Drum A Key Component of Agricultural Machinery

Agricultural machinery plays a vital role in modern farming, enhancing productivity and efficiency across various tasks. Among the critical components of these machines, the brake system, particularly the brake drum, stands out for its significance in ensuring safety and performance. The tractor brake drum is an essential part of the braking system, and understanding its function, maintenance, and impact on operational efficiency is crucial for farmers and equipment operators alike.

Function of the Brake Drum

The primary function of the brake drum is to provide a surface against which brake shoes press in order to slow down or stop the rotation of the wheels. When the operator engages the brakes, hydraulic pressure forces the brake shoes against the inner surface of the drum. This contact generates friction, which converts the kinetic energy of the moving tractor into heat, thereby slowing down the machine.

Brake drums are typically made from cast iron or other durable materials that can withstand high temperatures and stress. The design of the brake drum is essential; its diameter and surface area influence the overall braking efficiency. Larger drums can dissipate heat better and offer increased stopping power, making them effective for heavy-duty tractors that perform demanding tasks.

Types of Brake Drums

Tractors may utilize various types of braking mechanisms, including conventional drum brakes and more advanced systems such as disc brakes. Conventional brake drums are more common in older models or specific applications. They offer a reliable and cost-effective solution for agricultural machinery, particularly for tasks requiring substantial stopping power over rugged terrain.

On the other hand, disc brake systems have gained popularity in modern tractor designs due to their superior heat dissipation and reduced fading under heavy use. While disc brakes are often more expensive and complex than drum brakes, their performance advantages make them a preferred choice for high-efficiency farming operations.

Maintenance of Brake Drums

tractor brake drum

Maintaining the brake drum is vital for the safety and efficiency of the tractor. Regular inspections should be conducted to check for wear and tear, as worn brake shoes can lead to reduced braking performance and increased stopping distances. Signs of damage or excessive wear on the brake drum itself, such as deep grooves, cracks, or overheating, should prompt immediate attention.

Cleaning the drum and brake assembly is also an essential aspect of maintenance. Accumulated debris, mud, or debris can hinder braking efficiency and lead to uneven wear on the components. A thorough cleaning regimen can prolong the life of the brake system and ensure consistent performance.

Moreover, it is crucial to replace brake shoes when they become worn and to recondition or replace the brake drums as necessary. Most manufacturers provide specifications for minimum thickness and wear limits, which should guide maintenance schedules.

The Impact of Brake Drum Performance on Operations

The performance of the brake drum has a direct impact on the operational efficiency of the tractor. An effective braking system enhances safety, allowing operators to execute tasks with confidence, even in challenging conditions. Additionally, tractors equipped with well-maintained brake systems can reduce wear on other components, such as tires and transmissions, ultimately lowering the cost of maintenance and repair over time.

Moreover, in agricultural settings, where tractors often navigate uneven terrain and perform various tasks, reliable braking performance becomes essential. Whether plowing fields, hauling loads, or executing precise maneuvers, a responsive brake system provides operators with the control and safety necessary to avoid accidents and mishaps.

Conclusion

The tractor brake drum may appear to be a simple component, but its role in agricultural machinery is far more significant than it meets the eye. By understanding its function, types, and maintenance, farmers and equipment operators can ensure their machinery operates efficiently and safely. As the farming industry continues to evolve with advancements in technology, maintaining the integrity of critical components like the brake drum will remain essential in maximizing both productivity and safety on the field. Whether using older models or cutting-edge tractors, attention to the braking system will contribute to smoother, more efficient farming operations.

-

Durable Brake Drum MAZ for Heavy Duty Trucks | High Performance

NewsAug.26,2025

-

FUWA: Premium Quality, Reliable Performance & Innovative Solutions

NewsAug.25,2025

-

Liza Brake Drum: Superior Quality & Performance for Safe Driving

NewsAug.24,2025

-

Iveco Brake Drum | Premium OE Quality for Daily & Eurocargo

NewsAug.22,2025

-

Your Brake Drum Man: Quality & Performance Parts

NewsAug.21,2025

-

Explore Japan: Ultimate Travel Guide & Authentic Experiences

NewsAug.19,2025