Jan . 25, 2025 02:20 Back to list

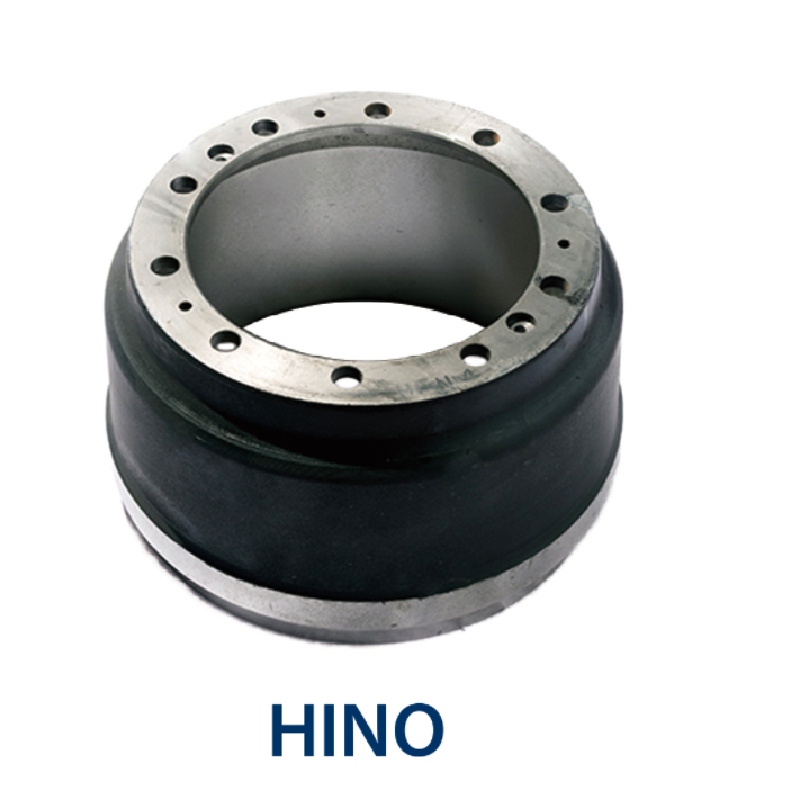

truck brake drum

When it comes to ensuring the safety and reliability of heavy-duty vehicles, the centerpiece that often demands attention is the truck brake drum. As an integral component of the braking system, the brake drum not only plays a critical role but also occasionally finds itself surrounded by a cloud of mystery regarding its proper selection, use, and maintenance. This article unveils the nuances of truck brake drums, emphasizing the importance of optimizing safety and performance.

Installation and maintenance practices further impact the effectiveness of the brake drum. Expert installers understand that precision is key. Ensuring that the drum is fitted correctly and inspected regularly can prevent common issues such as brake fade or uneven wear patterns, which ultimately affect braking efficiency and safety. In this regard, a well-maintained brake drum not only enhances trust in the vehicle but also affirms the reliability of the entire fleet. When it comes to brake drum replacement, trusting authoritative guidance is essential. Mechanics and technicians with expertise in truck maintenance can provide invaluable advice based on real-world experiences and thorough understanding of brake dynamics. This translates into selecting drums that align perfectly with vehicular needs — from the everyday delivery truck to the long-haul freight carrier. Furthermore, advancements in technology offer new solutions and insights into optimizing brake drum usage. Trusted manufacturers are now integrating innovative materials and designs aimed at reducing weight without sacrificing strength, thereby enhancing fuel efficiency and reducing overall operational costs. Additionally, digital platforms provide real-time monitoring of brake components, allowing for timely interventions and preemptive maintenance actions. In conclusion, the truck brake drum is more than a mere component; it's a linchpin for vehicular safety and efficiency. Through informed selection, expert installation, and authoritative maintenance practices, truck operators can bank on their brake systems' trustworthiness and performance, ultimately ensuring a smoother and safer journey. With the right blend of expertise and experience, truck brake drums become a testament to the reliability and integrity of heavy-duty vehicles on every road they tread.

Installation and maintenance practices further impact the effectiveness of the brake drum. Expert installers understand that precision is key. Ensuring that the drum is fitted correctly and inspected regularly can prevent common issues such as brake fade or uneven wear patterns, which ultimately affect braking efficiency and safety. In this regard, a well-maintained brake drum not only enhances trust in the vehicle but also affirms the reliability of the entire fleet. When it comes to brake drum replacement, trusting authoritative guidance is essential. Mechanics and technicians with expertise in truck maintenance can provide invaluable advice based on real-world experiences and thorough understanding of brake dynamics. This translates into selecting drums that align perfectly with vehicular needs — from the everyday delivery truck to the long-haul freight carrier. Furthermore, advancements in technology offer new solutions and insights into optimizing brake drum usage. Trusted manufacturers are now integrating innovative materials and designs aimed at reducing weight without sacrificing strength, thereby enhancing fuel efficiency and reducing overall operational costs. Additionally, digital platforms provide real-time monitoring of brake components, allowing for timely interventions and preemptive maintenance actions. In conclusion, the truck brake drum is more than a mere component; it's a linchpin for vehicular safety and efficiency. Through informed selection, expert installation, and authoritative maintenance practices, truck operators can bank on their brake systems' trustworthiness and performance, ultimately ensuring a smoother and safer journey. With the right blend of expertise and experience, truck brake drums become a testament to the reliability and integrity of heavy-duty vehicles on every road they tread.

Next:

Latest news

-

HINO Industrial Solutions - ¡Ң���ຽ��е��������˾ | Advanced Efficiency&Customization

NewsJul.13,2025

-

HINO Industrial Efficiency Solutions - ¡Ң���ຽ��е��������˾

NewsJul.13,2025

-

HINO Industrial Solutions - ¡Ң���ຽ��е��������˾ | Advanced Technology&Reliability

NewsJul.13,2025

-

HINO Industrial Efficiency-Jiangsu Hino Industrial|Productivity Optimization&Cost Reduction

NewsJul.12,2025

-

HINO-¡Ң���ຽ��е��������˾|Advanced Industrial Solutions&Energy Efficiency

NewsJul.12,2025

-

Premium Brake Drum Iveco – Durable Drum Brake Drum & Brake Shoe Solutions

NewsJul.08,2025