Aug . 17, 2024 15:56 Back to list

Understanding Brake Drum Shoes and Their Importance in Vehicle Safety

Understanding Brake Drum Shoes Function, Importance, and Maintenance

Brake drum shoes play a crucial role in the braking system of many vehicles, particularly in older models and some light trucks. The effectiveness of the braking system is paramount for safety on the road, and understanding how brake drum shoes function can illuminate their importance.

What Are Brake Drum Shoes?

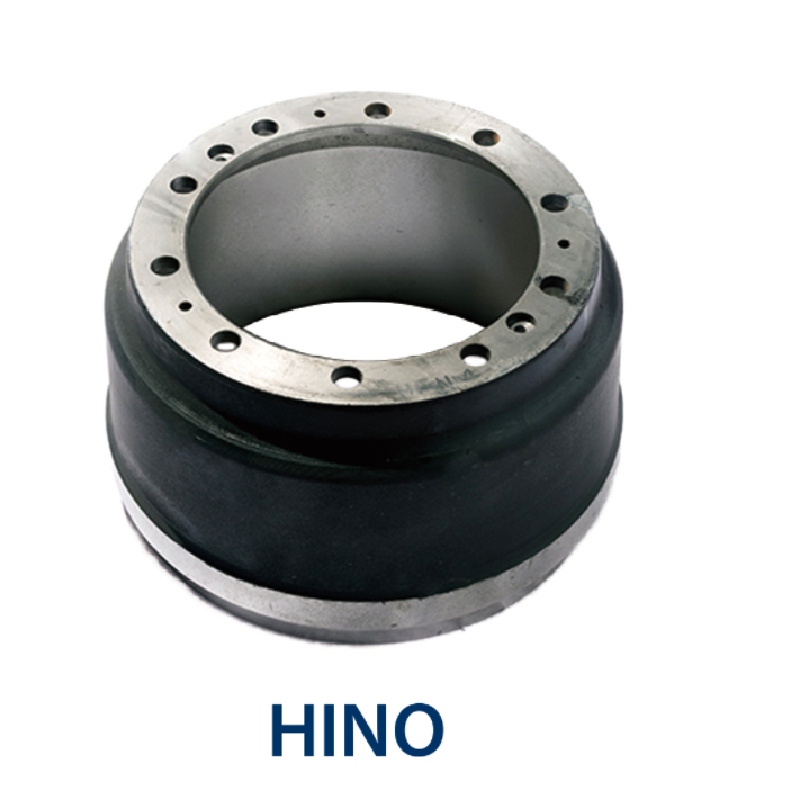

Brake drum shoes are curved friction components that press against the inside surface of a brake drum to create the friction necessary for stopping a vehicle. When the brake pedal is pressed, hydraulic pressure is generated, pushing the shoes outward against the drum. This frictional force slows down the vehicle by converting kinetic energy into heat.

Components of Brake Drum Shoes

Brake drum shoes are made of several materials, including a base plate, friction material, and a lining. The base plate provides structural integrity, while the friction material is designed to withstand high temperatures and wear from friction. Over the years, manufacturers have developed various types of friction materials, such as organic, semi-metallic, and ceramics, each with their unique properties suitable for different driving needs and environments.

The Importance of Brake Drum Shoes

The primary function of brake drum shoes is to ensure effective braking. Properly functioning drum shoes can significantly enhance a vehicle's stopping power, contributing to overall safety. They are particularly beneficial in applications requiring heavy and continuous braking, such as in trucks and buses.

Furthermore, drum brakes are known for their self-energizing effect, which means that they can apply additional force to the drum; this feature makes them particularly effective compared to disc brakes in certain conditions.

Another advantage of brake drum shoes is that they are generally less susceptible to water and dirt effects compared to disc brakes, leading to more reliable performance in wet or harsh conditions

.brake drum shoes

Signs of Worn or Damaged Brake Drum Shoes

Understanding the indicators of worn or damaged brake drum shoes is vital for vehicle maintenance. Common signs include

1. Squeaking or Squealing Noises A high-pitched noise when braking can indicate that the friction material is worn down. 2. Grinding Sounds If the shoes have worn down significantly, the backing plate may start to grind against the drum, which requires immediate attention.

3. Reduced Braking Efficiency If you notice longer stopping distances or a spongy pedal feel, it may be time to inspect the brake drum shoes.

4. Pulling to One Side If your vehicle pulls to one side while braking, this could indicate uneven wear on the drum shoes.

Maintenance and Replacement

Regular maintenance of brake drum shoes is essential for safe operation. Inspecting the brake system regularly allows for early detection of wear. Most mechanics recommend checking the brake shoes every 20,000 to 30,000 miles, although this can vary depending on driving conditions and vehicle usage.

When replacing brake drum shoes, it’s vital to choose high-quality parts that meet or exceed manufacturer specifications. Proper installation is equally crucial to ensure even wear and effective braking performance.

In conclusion, brake drum shoes are an integral component of a vehicle's braking system. Understanding their functionality, maintaining them properly, and recognizing signs of wear can lead to increased safety and better vehicle performance. Regular inspections and timely replacements not only ensure functionality but also help drivers maintain control on the road, ultimately protecting lives.

-

Scania Brake Drums: OEM Quality for Optimal Safety & Durability

NewsAug.16,2025

-

R.V.I: Advanced Remote Visual Inspection for Precision

NewsAug.15,2025

-

Discover HYUNDA: Innovative Vehicles, Equipment & Solutions

NewsAug.14,2025

-

R.V.I: Unlock Advanced Insights & Real-time Performance

NewsAug.13,2025

-

Kamaz Brake Drum: Durable & Reliable for Heavy Duty Trucks

NewsAug.12,2025

-

Heavy Duty Iveco Brake Drum - Premium Quality & Safety

NewsAug.11,2025