Jan . 25, 2025 04:18 Back to list

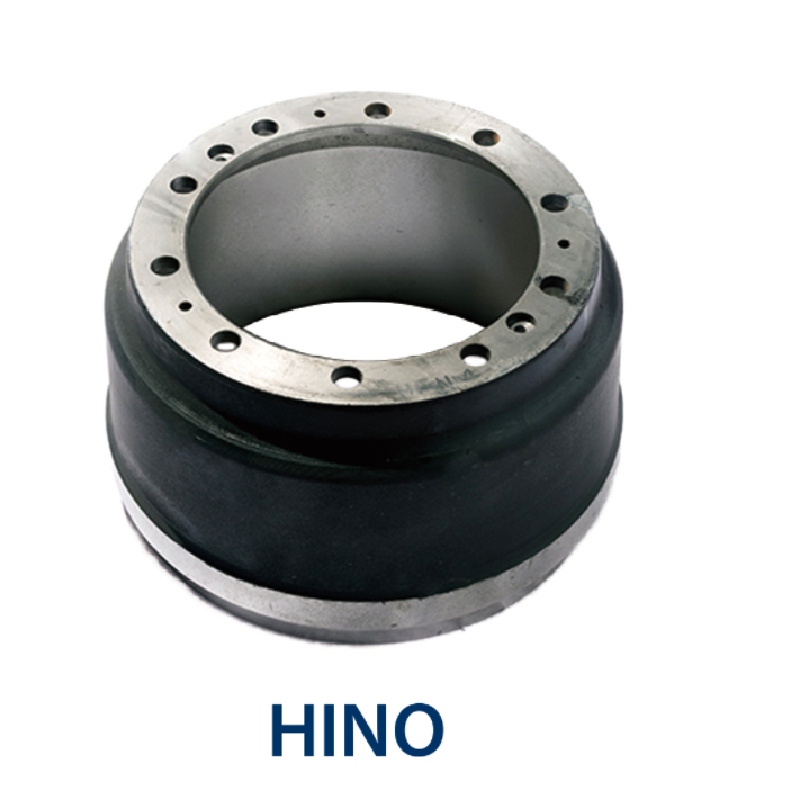

webb brake drums

In the intricate realm of automotive components, vehicle brake drums hold a pivotal position, often underappreciated yet critical to a vehicle's safety and performance. Our exploration delves deep into the multifaceted world of brake drums, unraveling their significance, functionality, and the nuanced expertise required for their maintenance and selection.

A deeper dive into the science of friction and braking dynamics reveals that brake drums are not isolated components. Their performance is intertwined with that of the brake shoes. Thus, a comprehensive maintenance regimen involves the simultaneous evaluation of both components. Ensuring that brake shoes are of high quality and compatible with the drums enhances the overall efficacy of the braking system. Beyond technical specifications and maintenance practices, the choice of supplier also influences the quality of brake drums. Reputable manufacturers adhere to stringent quality control protocols that include rigorous testing under various stress scenarios. This adherence to high standards not only guarantees product reliability but also reinforces trust in the brand. Finally, the future of brake drums is being shaped by emerging technologies and environmental considerations. The quest for sustainable and eco-friendly components has prompted research into alternative materials and production methods. The integration of smart technologies promises to revolutionize brake systems, with sensors monitoring real-time wear and performance metrics, thereby preempting failures and optimizing replacement cycles. In conclusion, the world of vehicle brake drums is one of precision, expertise, and continual evolution. Their role in vehicle safety is non-negotiable, necessitating a comprehensive understanding of their functionalities and maintenance requirements. As advancements continue to unfold, staying informed and updated with the latest developments ensures not only the optimal performance of brake drums but also the safety and reliability of the vehicles they serve. The synergy between expert knowledge, authoritative supplier relationships, and trustworthy maintenance practices forms the foundation from which superior brake drum performance is achieved and sustained.

A deeper dive into the science of friction and braking dynamics reveals that brake drums are not isolated components. Their performance is intertwined with that of the brake shoes. Thus, a comprehensive maintenance regimen involves the simultaneous evaluation of both components. Ensuring that brake shoes are of high quality and compatible with the drums enhances the overall efficacy of the braking system. Beyond technical specifications and maintenance practices, the choice of supplier also influences the quality of brake drums. Reputable manufacturers adhere to stringent quality control protocols that include rigorous testing under various stress scenarios. This adherence to high standards not only guarantees product reliability but also reinforces trust in the brand. Finally, the future of brake drums is being shaped by emerging technologies and environmental considerations. The quest for sustainable and eco-friendly components has prompted research into alternative materials and production methods. The integration of smart technologies promises to revolutionize brake systems, with sensors monitoring real-time wear and performance metrics, thereby preempting failures and optimizing replacement cycles. In conclusion, the world of vehicle brake drums is one of precision, expertise, and continual evolution. Their role in vehicle safety is non-negotiable, necessitating a comprehensive understanding of their functionalities and maintenance requirements. As advancements continue to unfold, staying informed and updated with the latest developments ensures not only the optimal performance of brake drums but also the safety and reliability of the vehicles they serve. The synergy between expert knowledge, authoritative supplier relationships, and trustworthy maintenance practices forms the foundation from which superior brake drum performance is achieved and sustained.

Next:

Latest news

-

HINO Industrial Solutions - ¡Ң���ຽ��е��������˾ | Advanced Efficiency&Customization

NewsJul.13,2025

-

HINO Industrial Efficiency Solutions - ¡Ң���ຽ��е��������˾

NewsJul.13,2025

-

HINO Industrial Solutions - ¡Ң���ຽ��е��������˾ | Advanced Technology&Reliability

NewsJul.13,2025

-

HINO Industrial Efficiency-Jiangsu Hino Industrial|Productivity Optimization&Cost Reduction

NewsJul.12,2025

-

HINO-¡Ң���ຽ��е��������˾|Advanced Industrial Solutions&Energy Efficiency

NewsJul.12,2025

-

Premium Brake Drum Iveco – Durable Drum Brake Drum & Brake Shoe Solutions

NewsJul.08,2025