ਨਵੰ. . 05, 2024 02:17 Back to list

semi truck brake drum thickness

Understanding Semi-Truck Brake Drum Thickness Importance and Maintenance

Semi-trucks, the backbone of the freight transportation industry, are equipped with robust braking systems that ensure safety and efficiency on our roads. Among the critical components of these braking systems are the brake drums, which play a vital role in slowing down and stopping the vehicle. One crucial aspect that fleet managers and truck operators must monitor is the thickness of the brake drums. This article will explore the importance of brake drum thickness, the consequences of neglecting it, and best practices for maintenance.

The Role of Brake Drums

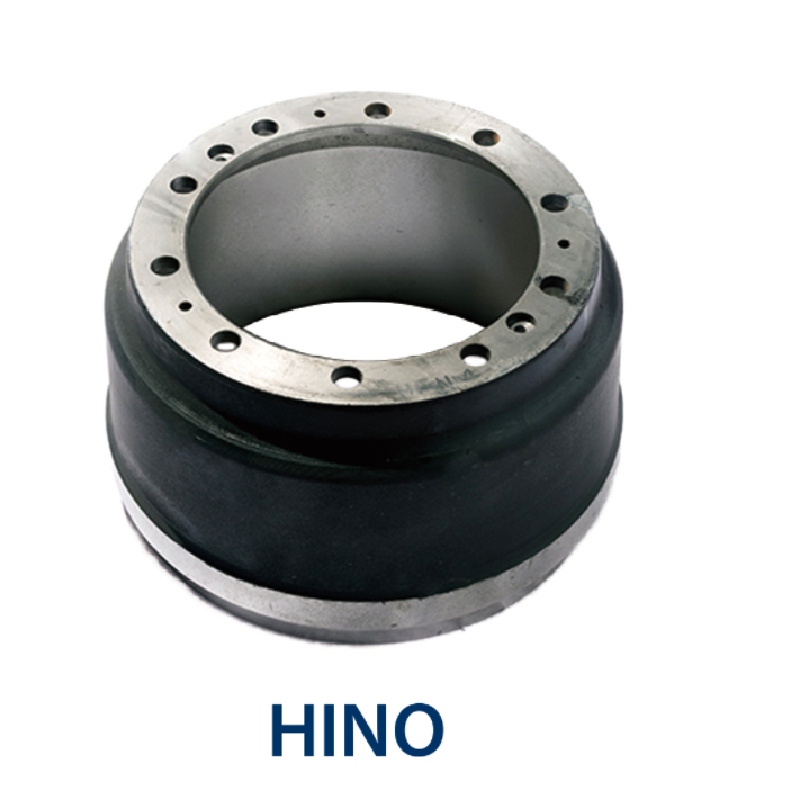

Before delving into the specifics of thickness, it’s essential to understand what brake drums are and their function. Brake drums are cylindrical components that house the brake shoes. When the brake pedal is engaged, the brake shoes expand against the inside surface of the drum, creating friction that slows down the wheel's rotation. This process is fundamental to a truck’s ability to stop quickly and safely.

Importance of Brake Drum Thickness

Brake drum thickness is a critical measurement for maintaining effective braking performance. Manufacturers specify certain thicknesses for their drums based on safety and performance parameters. When measuring the thickness, it’s important to note that the drum will wear over time due to continuous friction. As the material wears away, it can lead to several issues, including

1. Reduced Braking Efficiency Thinner drums can result in diminished friction capabilities, leading to longer stopping distances. This not only compromises the safety of the driver but also endangers other road users.

2. Heat Buildup As the drums wear down, they become less effective at dissipating heat generated during braking. Excessive heat can lead to brake fade, which significantly reduces braking power and can even lead to brake failure.

3. Drum Cracking or Warping When the thickness drops below the manufacturer’s recommended level, the risk of cracking or warping increases. This can further lead to more severe complications and costly repairs, requiring drum replacement.

4. Increased Maintenance Costs When drum thickness is not monitored, it can lead to cascading problems within the braking system. This increases maintenance costs and downtime, which can affect overall operational efficiency.

Measuring Brake Drum Thickness

semi truck brake drum thickness

To effectively monitor brake drum thickness, fleet managers and drivers should adopt a regular inspection routine. Using a micrometer or caliper, technicians can measure the inner diameter of the drum. Manufacturers typically provide a minimum thickness specification that must not be exceeded. Maintaining records of these measurements can help anticipate when drums will need to be replaced.

Best Practices for Maintenance

To extend the life of brake drums and maintain optimal thickness, consider the following best practices

1. Regular Inspections Schedule routine checks to assess wear and discoloration. Look for signs of heat damage, cracks, or excessive wear. Inspections should be part of any pre-trip vehicle check.

2. Proper Brake Adjustment Ensure that brake systems are regularly adjusted and well-maintained. Imbalances in braking force can lead to uneven wear on the drums and shoes.

3. Use Quality Parts When replacing brake drums, invest in quality parts that meet or exceed manufacturer specifications. High-quality materials typically provide better wear resistance.

4. Driving Habits Encourage drivers to adopt smooth braking techniques. Sudden and aggressive braking can exponentially reduce brake component lifespan.

5. Monitor Loads Ensure that trucks are loaded within their weight limits. Overloading can place extra strain on the braking system, leading to premature wear.

Conclusion

In the realm of semi-truck maintenance, brake drum thickness is a critical parameter that should never be overlooked. By ensuring that brake drums remain within safe thickness limits, fleets can maintain safety, improve efficiency, and reduce long-term costs associated with brake system failures. Regular inspections, maintenance, and driver education play vital roles in preserving the integrity of a truck's braking systems, ultimately contributing to safer roads and more reliable transport operations. As the demand for freight transport continues to grow, the importance of maintaining brake drum thickness cannot be overstated.

-

Volvo Brake Drum: OEM Quality, Optimal Safety

NewsAug.27,2025

-

Durable Brake Drum MAZ for Heavy Duty Trucks | High Performance

NewsAug.26,2025

-

FUWA: Premium Quality, Reliable Performance & Innovative Solutions

NewsAug.25,2025

-

Liza Brake Drum: Superior Quality & Performance for Safe Driving

NewsAug.24,2025

-

Iveco Brake Drum | Premium OE Quality for Daily & Eurocargo

NewsAug.22,2025

-

Your Brake Drum Man: Quality & Performance Parts

NewsAug.21,2025