Oct . 17, 2024 03:36 Back to list

semi truck brake drum size

Understanding Semi Truck Brake Drum Sizes

Semi trucks, also known as tractor-trailers or big rigs, are massive vehicles that transport goods across long distances. A critical component of their safety and performance is the brake system, particularly the brake drums. Brake drums are crucial for slowing down and stopping the vehicle, making it essential for drivers and fleet owners to understand their sizes and specifications.

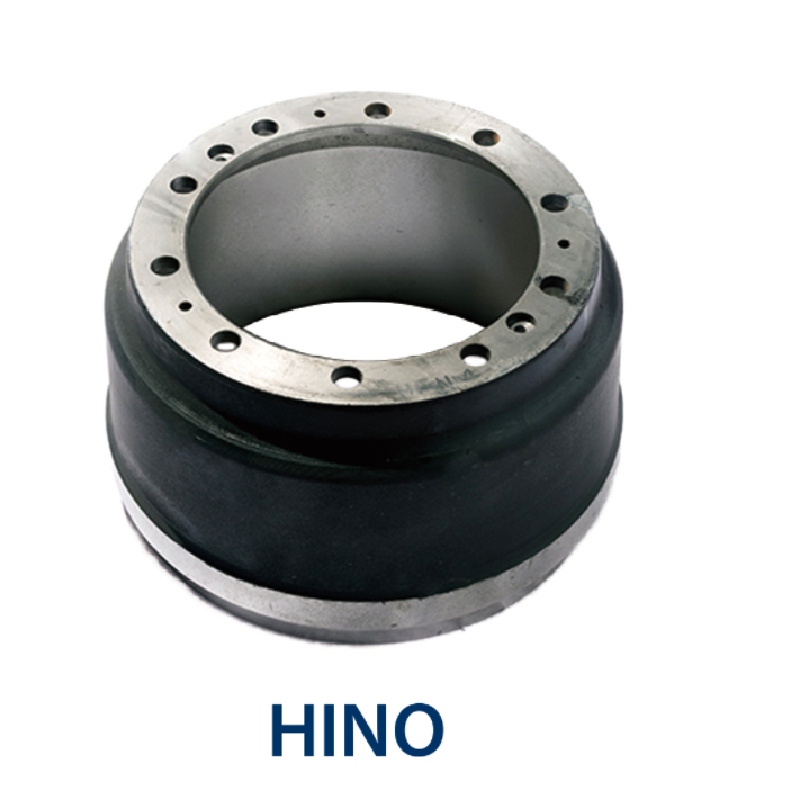

What Are Brake Drums?

Brake drums are round metal housings that encase the brake shoes in drum brake systems. When the driver applies the brakes, the brake shoes expand against the inside of the drum, creating friction that slows the vehicle down. Given the sheer size and weight of semi trucks—often exceeding 80,000 pounds when fully loaded—the brake drums must be robust and specifically designed to handle significant stress.

Common Brake Drum Sizes

Semi truck brake drums come in various sizes, typically ranging from 15 inches to 16.5 inches in diameter. However, the most common size for heavy-duty trucks is 16.5 inches, which fits a standard wheel size and provides adequate braking performance. The width of the drums can also vary, commonly found between 7 inches and 8.75 inches. Selecting the proper size is critical as it must align with the truck's axle configuration and brake system.

Factors Affecting Brake Drum Size Selection

1. Vehicle Weight Heavier trucks require larger and more robust brake drums to ensure effective braking. The weight dictates the amount of friction needed to bring the vehicle to a stop safely.

semi truck brake drum size

2. Load Capacity Different types of loads can affect the brake performance. For example, a truck carrying a full load of cargo will require larger brake drums than one running empty.

3. Brake System Type Not all semi trucks use the same braking system. Some might utilize air brakes, while others might have hydraulic systems. The design of the braking system influences the required drum size and specifications.

4. Driving Conditions Trucks operating in mountainous regions or those frequently affected by stop-and-go traffic may require larger brake drums for improved heat dissipation and performance.

Importance of Regular Maintenance

Regular checks and maintenance of brake drums are vital for safety and performance. Over time, brake drums can wear down, leading to reduced braking efficiency, which can be dangerous, especially when carrying heavy loads. Fleet managers and truck owners should regularly inspect the brake drums for signs of wear and tear, such as scoring, cracks, or excessive heat signs.

Replacing worn brake drums promptly can prevent costly repairs and accidents, ensuring that the truck operates safely on the road.

Conclusion

Understanding semi truck brake drum sizes and their specifications is essential for safety and operational efficiency. Fleet managers and drivers should pay keen attention to the size requirements based on vehicle weight, load capacity, and driving conditions. Additionally, regular maintenance can prolong the life of brake components and enhance safety on the road. By staying informed and proactive, truck operators can ensure reliable performance in their braking systems, safeguarding both drivers and cargo alike.

-

Brake Drum Liza Durable & High-Performance Brake Solutions

NewsMay.29,2025

-

Brake Drum Liza Durable Drum Brake & Shoe Replacement Solutions

NewsMay.29,2025

-

Brake Drum Liza High-Quality Drum Brake & Shoe Solutions

NewsMay.29,2025

-

Brake Drum Liza Durable Drum Brake & Shoe Solutions for Vehicles

NewsMay.29,2025

-

Brake Drum Liza Premium Drum Brake Components & Shoes

NewsMay.29,2025

-

Brake Drum Man Durable Drum Brake Drums & Shoes Supplier

NewsMay.28,2025