Dec . 04, 2024 20:23 Back to list

Understanding the Mechanics of Band Brake Drum Systems and Their Applications

Understanding Band Brake Drums Mechanics and Applications

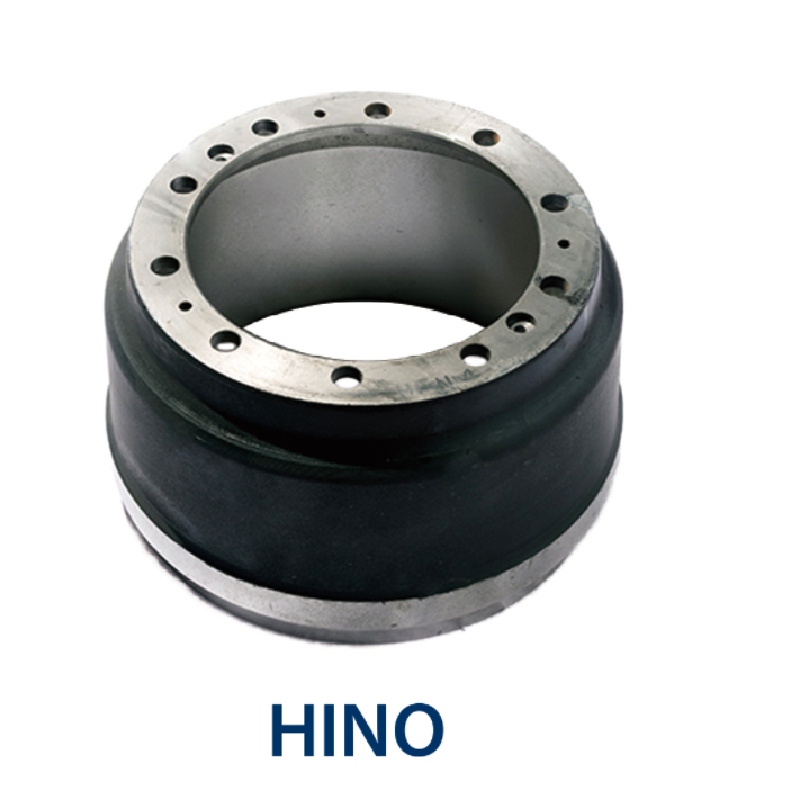

Band brake drums are integral components found in various mechanical systems, primarily in vehicles and machinery. They are known for their efficiency in controlling motion and ensuring safety through effective braking mechanisms. This article will explore the unique characteristics of band brake drums, their functionality, and their various applications across different industries.

What is a Band Brake Drum?

A band brake drum comprises two primary elements the brake drum itself and the band that wraps around it. The brake drum is typically made of durable materials such as cast iron or steel, designed to withstand high temperatures and pressures generated during braking. The band, usually made of flexible yet tough materials, applies friction against the drum’s surface when the braking system is engaged.

The operation of a band brake drum is fundamental to its design. When the braking system is activated, the band tightens around the drum, creating friction that slows down the drum’s rotation. This mechanism is particularly advantageous in applications requiring consistent and reliable braking power.

Mechanism of Action

The principle behind band brake drums is straightforward. When the driver or operator wants to slow down or stop a vehicle or machine, they engage the brake lever or pedal. This action activates a mechanism that pulls the brake band taut around the drum. The friction generated between the band and the drum slows down the spinning motion, effectively bringing the system to a halt.

One of the key advantages of band brake drums is their ability to distribute braking force evenly along the surface of the drum, leading to more efficient and controlled braking. It reduces the risk of overheating, which can lead to brake fade—an occurrence where brakes lose their effectiveness due to heat accumulation.

band brake drum

Applications of Band Brake Drums

Band brake drums are commonly found in various applications, such as

1. Automobiles Many older vehicles utilize band brake systems, especially in rear drum brakes, where space and weight considerations are crucial. While newer technologies have emerged, band brakes are still prevalent in some models for their simplicity and effectiveness.

2. Industrial Machinery In manufacturing settings, band brake drums are used in hoists, elevators, and other heavy equipment where precise control over movement is necessary. They provide reliable stopping power for heavy loads, ensuring safety in operations.

3. Motorcycles and Bicycles Some motorcycles and bicycles, especially older models, still rely on band brake designs. They offer a lightweight and compact braking solution, which is essential in these vehicles.

4. Trains and Trams Certain rail systems utilize band brakes for their ability to deliver consistent braking performance over extended periods, making them ideal for stopping heavy vehicles like trains.

Conclusion

Band brake drums play a critical role in various mechanical and automotive systems, leveraging the principles of friction and physics to ensure safety and control. Their design allows for effective heat management and even distribution of braking forces, making them highly reliable. While newer braking technologies continue to evolve, band brake drums remain a testament to the effectiveness of traditional engineering principles. As industries advance, understanding these fundamental components will continue to inform innovations in braking systems, ensuring safety and efficiency in motion control.

-

HINO Industrial Solutions - ¡Ң���ຽ��е��������˾ | Advanced Efficiency&Customization

NewsJul.13,2025

-

HINO Industrial Efficiency Solutions - ¡Ң���ຽ��е��������˾

NewsJul.13,2025

-

HINO Industrial Solutions - ¡Ң���ຽ��е��������˾ | Advanced Technology&Reliability

NewsJul.13,2025

-

HINO Industrial Efficiency-Jiangsu Hino Industrial|Productivity Optimization&Cost Reduction

NewsJul.12,2025

-

HINO-¡Ң���ຽ��е��������˾|Advanced Industrial Solutions&Energy Efficiency

NewsJul.12,2025

-

Premium Brake Drum Iveco – Durable Drum Brake Drum & Brake Shoe Solutions

NewsJul.08,2025