Окт . 31, 2024 22:47 Back to list

Guide to Choosing Brake Drums for Semi Trucks and Enhancing Vehicle Performance

Brake Drums for Semi Trucks An Essential Component of Heavy-Duty Vehicles

Brake drums play a critical role in the efficient and safe operation of semi trucks. These vehicles, known for their size and weight, rely heavily on effective braking systems to ensure the safety of the driver and surrounding vehicles. Brake drums are an essential component of the drum brake system, which has been widely used in heavy-duty vehicles for many years. Understanding how brake drums function and their importance can help truck owners and operators ensure safety and performance on the road.

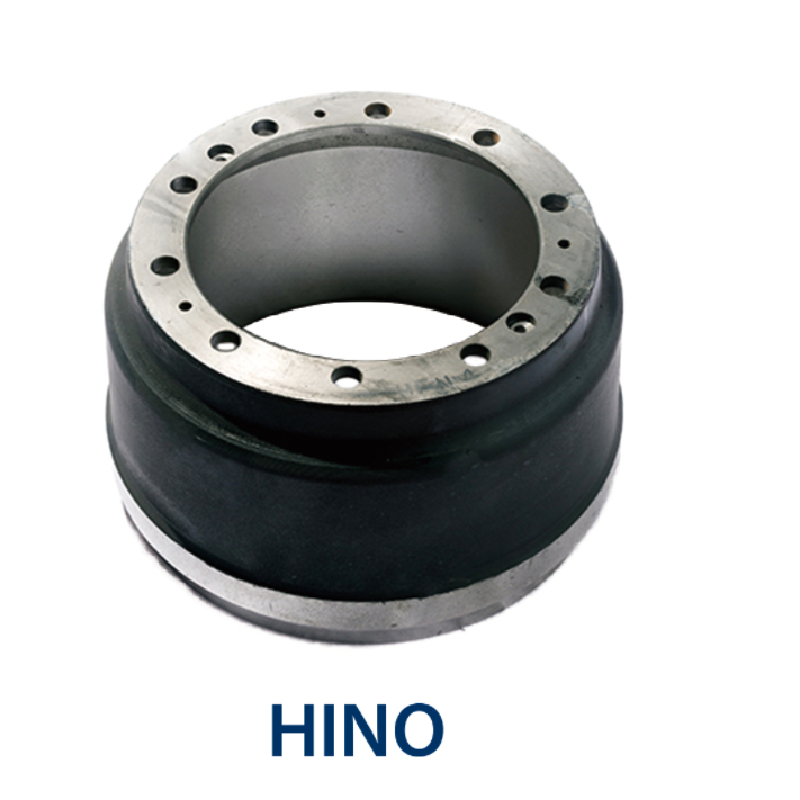

What Are Brake Drums?

Brake drums are cylindrical components made of cast iron or aluminum, designed to house the braking mechanism. When drivers apply the brakes, the brake shoes inside the drum press against the inner surface, creating friction. This friction slows down or stops the rotation of the wheels. Given the significant weight of semi trucks, which can exceed 80,000 pounds when fully loaded, the braking system must be robust and reliable.

The Importance of Material and Design

The material and design of brake drums are crucial for their performance. Cast iron is the most common material, known for its heat-resistant properties and durability. However, some manufacturers are increasingly using lightweight aluminum alloys. These materials can offer advantages in reducing overall vehicle weight, which enhances fuel efficiency without compromising safety.

The design of the brake drum also impacts its cooling and performance. Ventilated brake drums, for example, allow for better heat dissipation during braking, which is essential during long hauls on highways. Overheating can lead to brake fade, a dangerous condition where brakes lose effectiveness.

Maintenance and Replacement Considerations

brake drums for semi truck

Regular maintenance of brake drums is vital for ensuring safe operation. Routine inspections should include checking for signs of wear, such as scoring or cracking on the inner surface. If the drums have worn beyond their specified limits, they should be replaced to prevent brake failure.

Changing brake drums involves not only replacing the worn parts but also inspecting related components such as brake shoes and wheel bearings. It is advisable to replace these components in pairs to ensure even wear and consistent performance. Professionals recommend maintaining a schedule for routine checks and replacements to enhance safety and efficiency.

Innovations in Brake Technology

The trucking industry is seeing advancements in brake technology, including the introduction of automatic brake adjustment systems and improved composite materials for brake drums. These innovations aim to enhance performance, reduce maintenance costs, and improve overall safety.

Additionally, anti-lock braking systems (ABS) are becoming more prevalent in semi trucks. ABS helps prevent wheel locking during hard braking situations, thereby maintaining driver control and reducing the risk of accidents.

Conclusion

In conclusion, brake drums are vital components of a semi truck's braking system. Their design, material, and maintenance significantly impact the vehicle's safety and performance. As the trucking industry continues to evolve with new technologies, understanding the importance of brake drums and staying updated on maintenance practices will ensure safer travels on the road. Proper knowledge and attention to these components not only help in compliance with safety regulations but also enhance the longevity and reliability of semi trucks. Truck operators must prioritize these components as part of their overall vehicle maintenance plan to ensure their fleet operates efficiently and safely.

-

Brake Drum Liza Durable & High-Performance Brake Solutions

NewsMay.29,2025

-

Brake Drum Liza Durable Drum Brake & Shoe Replacement Solutions

NewsMay.29,2025

-

Brake Drum Liza High-Quality Drum Brake & Shoe Solutions

NewsMay.29,2025

-

Brake Drum Liza Durable Drum Brake & Shoe Solutions for Vehicles

NewsMay.29,2025

-

Brake Drum Liza Premium Drum Brake Components & Shoes

NewsMay.29,2025

-

Brake Drum Man Durable Drum Brake Drums & Shoes Supplier

NewsMay.28,2025