نويابىر . 11, 2024 14:39 Back to list

brake drum skimming machine

Brake Drum Skimming Machine Ensuring Safety and Performance

The brake system is an essential component of any vehicle, playing a pivotal role in ensuring safety by allowing the driver to slow down or stop efficiently. Among the various components of the brake system, the brake drum is crucial, especially in vehicles equipped with drum brakes. Over time, brake drums can wear out, leading to decreased performance and potential safety hazards. This is where the brake drum skimming machine comes into play, providing a vital service for maintaining brake efficiency and safety.

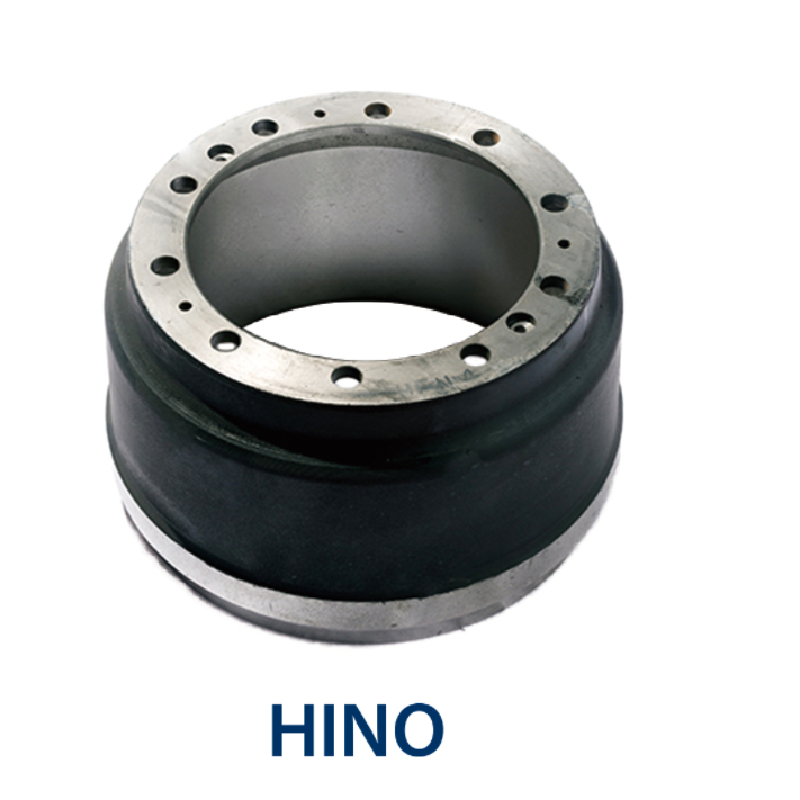

Understanding Brake Drums

Brake drums are cylindrical components that house the brake shoes and play a critical role in the operation of drum brakes. When the brake pedal is pressed, the brake shoes expand against the inside of the drum, creating friction that slows down the vehicle. With regular use, however, brake drums can develop warping, scoring, and wear. These issues can lead to several problems, including reduced braking efficiency, increased stopping distances, and uneven brake wear.

What is a Brake Drum Skimming Machine?

A brake drum skimming machine is a specialized tool designed to restore the surface of worn or damaged brake drums. By skimming the surface, the machine cuts away a thin layer of the drum, smoothing out imperfections and ensuring that the drum remains within the manufacturer’s specifications. This process helps restore the drum’s capacity to create uniform friction with the brake shoes, thereby enhancing overall braking performance.

How Does the Skimming Process Work?

The skimming process typically involves several steps to ensure a precise and effective outcome. First, the brake drum is removed from the vehicle, allowing access for the machine. The drum is then mounted securely in the skimming machine, where it is rotated at controlled speeds. As the drum spins, a cutting tool is brought into contact with the surface, meticulously removing material to create a smooth finish.

Modern machines often come equipped with advanced features, such as digital displays and automated depth control, which help technicians achieve accurate results. The skimming process can generally be completed within a short timeframe, making it a cost-effective solution for maintaining brake efficiency.

brake drum skimming machine

Benefits of Using a Brake Drum Skimming Machine

1. Improved Safety Skimming brake drums enhances the efficiency of the braking system, leading to shorter stopping distances and increased vehicle safety.

2. Cost-Effective Solution Instead of replacing worn brake drums, skimming can restore them to usable condition, saving money for vehicle owners.

3. Extended Component Life Proper maintenance of brake drums through skimming can extend their lifespan, reducing the frequency of replacements.

4. Reduction in Brake Noise Skimming can eliminate irregularities that may cause noise during braking, leading to a quieter driving experience.

5. Enhanced Performance A smooth brake drum enables better contact with the brake shoes, leading to improved performance and a more responsive braking action.

Conclusion

In conclusion, the brake drum skimming machine is an indispensable tool in automotive maintenance. It plays a crucial role in ensuring that brake drums remain effective and safe throughout their lifespan. As vehicles continue to evolve, so too does the technology behind brake systems, making regular maintenance more important than ever. By utilizing a brake drum skimming machine, vehicle owners can not only enhance their safety on the road but also ensure that their braking systems perform at optimal levels. Therefore, investing in this technology is not just about maintaining a vehicle; it's about committing to safety and reliability on the road.

-

Iveco Brake Drum | Premium OE Quality for Daily & Eurocargo

NewsAug.22,2025

-

Your Brake Drum Man: Quality & Performance Parts

NewsAug.21,2025

-

Explore Japan: Ultimate Travel Guide & Authentic Experiences

NewsAug.19,2025

-

Your Brake Drum Man: Premium & Reliable Brake Drums for Sale

NewsAug.18,2025

-

ROR Web Development: Build Fast, Scalable, Secure Apps

NewsAug.17,2025

-

Scania Brake Drums: OEM Quality for Optimal Safety & Durability

NewsAug.16,2025