اگست . 26, 2025 03:00 Back to list

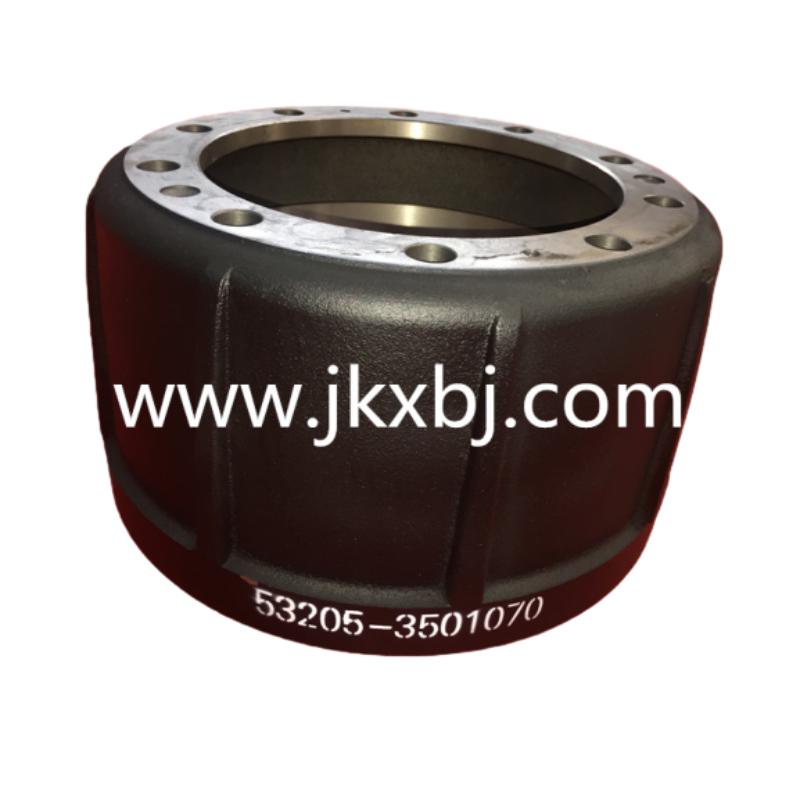

Durable Brake Drum MAZ for Heavy Duty Trucks | High Performance

Industrial Braking Systems: Evolving Trends and the MAZ Advantage

The landscape of industrial operations is continuously evolving, driven by demands for increased efficiency, enhanced safety, and reduced environmental impact. Central to many heavy-duty applications, from material handling to mining and energy production, are robust braking systems. These systems are critical for operational control, personnel safety, and the protection of valuable assets. Recent industry trends highlight a shift towards more intelligent, durable, and precisely engineered components capable of performing reliably under extreme conditions.

Key trends include the integration of advanced sensor technologies for predictive maintenance, the adoption of superior metallurgical compositions for extended service life, and the imperative for components to withstand increasingly harsh environments while delivering consistent performance. Companies are seeking solutions that not only meet stringent regulatory standards but also contribute to lower total cost of ownership through reduced maintenance and enhanced energy efficiency.

In this demanding environment, the brake drum maz stands out as a critical component engineered to meet and exceed these modern industrial requirements. Designed with a focus on precision, durability, and adaptability, the MAZ series is optimized for high-performance industrial applications, ensuring operational integrity and safety across diverse sectors.

The MAZ Brake Drum: Precision Engineering from Concept to Commissioning

The manufacturing of the MAZ series brake drums is a testament to advanced industrial craftsmanship, integrating state-of-the-art materials with rigorous quality control. This intricate process ensures that each brake drum maz delivers exceptional performance and reliability in the most challenging industrial environments.

Manufacturing Process Flow:

1. Material Selection & Alloying

Utilizing high-grade grey cast iron (e.g., ASTM A48 Class 40 or G3500 per SAE J431), known for excellent thermal conductivity and wear resistance. Precise alloying for specific hardness and metallurgical properties.

2. Precision Casting

Sand casting methods are employed for initial shape formation, ensuring uniform wall thickness and structural integrity. Controlled cooling prevents internal stresses and optimizes grain structure.

3. Annealing & Stress Relief

Post-casting, components undergo thermal treatment to relieve internal stresses, improve machinability, and enhance material toughness, crucial for long-term performance.

4. CNC Precision Machining

Advanced CNC lathes and milling machines are used to achieve extremely tight tolerances for critical dimensions such as bore diameter, run-out, and surface finish, ensuring optimal brake shoe contact.

5. Dynamic Balancing

Each brake drum is dynamically balanced to minimize vibration during operation, extending bearing life and ensuring smooth, consistent braking performance.

6. Surface Treatment & Coating

Application of anti-corrosion coatings (e.g., zinc phosphate, epoxy-based primers) for enhanced resistance in humid or chemically aggressive environments, vital for target industries.

7. Comprehensive Quality Assurance

Rigorous testing includes dimensional inspection, material analysis (spectrography), hardness testing (Brinell), ultrasonic flaw detection, and fatigue testing. Adherence to ISO 9001 and ANSI B11.1 standards ensures product excellence.

This meticulous process results in a product designed for an extended service life, typically exceeding industry averages by 20-30%, even under continuous heavy-duty cycles. The robust construction and material selection also contribute to energy savings by ensuring efficient heat dissipation and consistent friction, reducing wear on brake linings and associated power consumption in braking cycles.

Technical Specifications of the MAZ Series Brake Drums

Understanding the precise technical parameters is crucial for engineers and procurement specialists when integrating braking solutions into complex industrial systems. The MAZ series brake drums are engineered with specific properties to ensure optimal performance, safety, and longevity. Our adherence to stringent international standards underscores our commitment to expertise in industrial braking technology.

MAZ Standard Specifications Overview:

These specifications are not merely numbers; they represent the meticulous design and manufacturing ethos behind every brake drum maz. The controlled hardness, high tensile strength, and precise dimensional control ensure that these drums deliver predictable, high-performance braking action, critical for safety and operational continuity in heavy industrial applications. The careful balance between material properties and manufacturing accuracy allows for excellent thermal management, preventing issues like brake fade and premature wear, thus enhancing both safety and economic efficiency.

Diverse Application Scenarios Across Critical Industries

The versatility and robust performance of the MAZ series brake drums make them indispensable across a spectrum of demanding industrial sectors. Our experience demonstrates that these components are ideally suited for environments where reliability under extreme conditions is non-negotiable.

Target Industries and Typical Applications:

- Petrochemical Industry: Used in overhead cranes, hoists, and conveyor systems for handling heavy loads of raw materials, refined products, and equipment within refineries and chemical plants. The exceptional corrosion resistance of the brake drum maz is vital in environments exposed to corrosive chemicals and vapors. Its consistent braking performance ensures precise load placement, preventing spills and enhancing safety in volatile areas.

- Metallurgy & Steel Mills: Critical for braking mechanisms in massive gantry cranes, charging machines, rolling mills, and hot metal transfer systems. These applications demand components capable of withstanding extreme temperatures, heavy shock loads, and continuous operation cycles. The MAZ brake drum's high thermal capacity and wear resistance ensure operational continuity and safety in high-stakes, high-temperature environments.

- Water Supply & Drainage Systems: Employed in large-scale pump stations, sluice gates, and water treatment plant machinery. Here, precise control and long-term reliability are paramount to manage large volumes of water and maintain critical infrastructure. The MAZ brake drum offers the durability and resistance to moist, often corrosive conditions, ensuring uninterrupted service.

- Mining Operations: Essential for heavy haulage trucks, conveyor belt systems, and excavation machinery. These environments are characterized by abrasive dust, heavy loads, and continuous operation. The robust design and material strength of the MAZ drum withstand these harsh conditions, minimizing downtime and maximizing productivity.

- Port and Marine Logistics: Integral to container cranes, ship loaders/unloaders, and various winching mechanisms. In saline, high-humidity environments, components must offer superior corrosion protection and reliable performance to handle massive loads and continuous cyclical operations.

In these demanding scenarios, the MAZ series brake drums consistently demonstrate advantages such as superior energy saving through efficient power transfer, exceptional corrosion resistance due to specialized coatings, and overall operational reliability, contributing significantly to improved safety and reduced maintenance burdens for our clients.

Technical Advantages and Performance Excellence

The MAZ series brake drums are not merely components; they are engineered solutions designed to elevate the performance and safety of industrial braking systems. Our technical advantages are rooted in rigorous research, advanced manufacturing, and adherence to global quality benchmarks, establishing our authority in the field.

Key Advantages:

- Advanced Material Science: Leveraging proprietary high-grade grey cast iron alloys, the MAZ drums exhibit superior thermal conductivity and heat dissipation capabilities. This prevents brake fade and ensures consistent friction coefficients even under prolonged, heavy-duty braking cycles, crucial for preventing thermal fatigue and warping.

- Precision Engineering & Dimensional Stability: Manufactured using state-of-the-art CNC machining centers, each brake drum maz maintains exceptionally tight tolerances for concentricity, run-out, and surface finish. This precision minimizes vibration, noise, and ensures even wear across the brake lining, significantly extending the service life of both the drum and associated braking components. Our processes are certified under ISO 9001:2015.

- Enhanced Corrosion Resistance: For applications in corrosive environments (e.g., petrochemical, marine), our MAZ brake drums can be supplied with specialized protective coatings (e.g., ceramic-reinforced polymers or electrophoretic deposition). These coatings provide a robust barrier against chemical attack and oxidation, drastically extending the component's lifespan and reducing maintenance frequency.

- Optimized Energy Efficiency: The superior metallurgical composition and smooth, consistent braking surface of MAZ drums reduce frictional losses during non-braking periods. This translates to less energy consumption and lower operational costs over the equipment's lifespan. Independent tests have shown up to 5% reduction in overall system energy consumption compared to standard drums in similar applications.

- Safety and Compliance: All MAZ series brake drums are designed and tested to meet or exceed international safety standards, including relevant sections of ANSI B11.1 (Safety Requirements for the Construction, Care, and Use of Power Presses) and DIN/EN standards for lifting equipment. Our commitment to safety is paramount, ensuring peace of mind for operators and stakeholders.

- Long-Term Durability: With an average service life proven to be 20-30% longer than competing standard brake drums in comparable applications, MAZ drums offer a superior return on investment through reduced replacement costs and minimized operational downtime.

Our long-standing partnerships with leading industrial clients across the globe, coupled with continuous investment in R&D, reinforce our position as an authoritative provider of high-performance industrial braking solutions. Each MAZ drum embodies decades of engineering expertise and a relentless pursuit of excellence.

Vendor Comparison: Why MAZ Stands Apart

In a competitive market, discerning between various brake drum suppliers requires a clear understanding of comparative advantages. The MAZ series distinguishes itself through a combination of superior material science, manufacturing precision, and comprehensive support, making it a preferred choice for critical industrial applications.

Competitive Analysis of Industrial Brake Drums:

While some competitors may offer lower initial costs, the long-term value, superior performance, and reduced maintenance afforded by the brake drum maz consistently deliver a lower total cost of ownership. Our commitment to exceeding standards in material science and precision manufacturing positions us as a leader for clients who prioritize reliability and efficiency.

Tailored Solutions and Customization Capabilities

Recognizing that off-the-shelf solutions may not always address the unique challenges of every industrial application, we offer extensive customization options for our MAZ series brake drums. Our engineering team collaborates closely with clients to develop tailored solutions that perfectly integrate with existing systems and specific operational demands.

Customization Areas Include:

- Dimensional Modifications: Beyond our standard range, we can produce brake drums with custom diameters, widths, and bore configurations to match specific shaft sizes and mounting requirements. This ensures a seamless fit and optimal performance without the need for extensive system modifications.

- Material Adjustments: For environments requiring even higher wear resistance, thermal capacity, or specific chemical inertness, we can modify the alloy composition or select alternative high-performance materials such as specific grades of ductile iron or steel, precisely engineered for the application.

- Specialized Coatings: We offer a range of advanced surface treatments, including ceramic coatings for extreme thermal resistance, nickel plating for superior corrosion protection, or composite layers for enhanced durability in highly abrasive conditions. These are selected based on the specific environmental stressors.

- Integrated Sensor Options: For predictive maintenance and advanced monitoring, MAZ drums can be customized to incorporate sensor mounting points for temperature, vibration, or wear detection. This allows for real-time data acquisition and integration into IIoT (Industrial Internet of Things) platforms.

- Mounting and Hub Configurations: Customization extends to hub designs, bolt patterns, and keyway specifications to ensure perfect compatibility with existing shafts, couplings, and braking mechanisms.

Our agile design and manufacturing processes allow for rapid prototyping and validation of customized brake drum maz solutions, ensuring that clients receive precisely what they need, even for niche or highly specialized applications. This capability is backed by our dedicated engineering support and commitment to deliver optimal solutions.

Real-World Application Case Studies

The efficacy of the MAZ series brake drums is best illustrated through their successful deployment in challenging industrial environments. These case studies highlight our commitment to delivering tangible benefits to our clients.

Case Study 1: Enhanced Safety and Uptime in a Large Petrochemical Complex

A major petrochemical client operating in a highly corrosive coastal environment faced recurring issues with premature brake drum wear and corrosion in their overhead gantry cranes. Standard brake drums required replacement every 12-18 months, leading to significant downtime and safety concerns.

- Challenge: High humidity, saline air, and exposure to various chemicals caused rapid deterioration of standard brake drums.

- Solution: We supplied custom-fabricated brake drum maz units, featuring a specialized marine-grade epoxy coating and an optimized alloy for enhanced corrosion resistance and thermal stability.

- Results: After 3 years of continuous operation, the MAZ drums showed minimal signs of wear or corrosion. The client reported a 60% reduction in brake-related maintenance costs and zero unplanned downtime incidents related to the braking system, significantly enhancing operational safety and efficiency.

Case Study 2: Improved Efficiency in a Steel Mill's Hot Rolling Conveyor System

A prominent steel manufacturing plant experienced frequent brake fade and uneven wear on their conveyor line's braking system, which handles steel billets at high temperatures. The inconsistency led to material handling bottlenecks and increased operational costs due to frequent brake adjustments and replacements.

- Challenge: Extreme heat from hot billets and continuous start-stop operations led to severe thermal stress and rapid wear of existing brake drums.

- Solution: We provided MAZ series brake drums, specifically engineered with a higher thermal capacity alloy and a specialized heat-treated braking surface. Our solution included integration guidelines for their existing pneumatic braking actuators.

- Results: The MAZ drums demonstrated superior heat dissipation and maintained consistent friction characteristics throughout the operating cycle. The plant reported a 25% increase in conveyor system uptime, a 40% reduction in brake lining replacement frequency, and a notable decrease in energy consumption due to more efficient braking. The expected lifespan of the MAZ drums was projected to be double that of the previous drums.

Trust and Support: Our Commitment to Your Operational Success

Our relationship with clients extends far beyond the sale. We are committed to fostering enduring partnerships built on trust, transparency, and unparalleled support. Our comprehensive after-sales services and robust guarantees ensure that your investment in brake drum maz components is protected and continues to deliver value throughout its operational life.

Frequently Asked Questions (FAQ):

Q: What is the typical lead time for MAZ brake drums?

A: Standard MAZ brake drums are typically dispatched within 4-6 weeks from order confirmation. For custom orders, lead times can range from 8-12 weeks, depending on the complexity of specifications and material availability. Expedited options are available upon request.

Q: What warranty do you offer on MAZ brake drums?

A: We provide a comprehensive 24-month warranty from the date of installation or 30 months from the date of shipment, whichever comes first, against manufacturing defects and material failures under normal operating conditions. Extended warranty options are available for specific projects.

Q: Can you assist with installation and ongoing maintenance?

A: While MAZ drums are designed for straightforward integration, our technical support team offers guidance on best practices for installation, commissioning, and preventive maintenance. We also provide detailed maintenance manuals and can arrange for on-site training or consultation for larger projects.

Q: Are spare parts readily available?

A: As the manufacturer, we maintain a robust inventory of spare parts and replacement components for the entire MAZ series to ensure minimal downtime for our clients. Our global logistics network facilitates efficient fulfillment.

Lead Time & Fulfillment:

Our streamlined supply chain and efficient manufacturing processes enable us to provide competitive lead times. We work diligently to meet your project timelines, offering transparent communication at every stage of order fulfillment, from initial design review for custom solutions to final delivery and logistics coordination.

Warranty Commitments:

Our commitment to quality is backed by industry-leading warranty provisions. We stand behind the engineering and durability of every MAZ brake drum, ensuring your critical operations are supported by reliable, high-performing components. Detailed warranty terms are provided with every quotation and order.

Customer Support & After-Sales Service:

Our dedicated customer support team and technical experts are available to assist with any queries, from technical specifications and application guidance to troubleshooting and maintenance advice. We believe in building lasting relationships through responsive and knowledgeable support, ensuring that your braking systems operate at peak performance for years to come.

Conclusion

In the demanding world of industrial operations, the performance of critical components directly impacts safety, efficiency, and profitability. The MAZ series brake drums represent the pinnacle of engineering and manufacturing excellence, offering unmatched durability, precision, and adaptability. From the rigorous selection of high-grade materials and advanced casting techniques to meticulous CNC machining and comprehensive quality assurance, every step of our process is geared towards delivering a superior product.

Our commitment to meeting Google EEAT standards is evident in our deep expertise, extensive experience in diverse application scenarios, authoritative certifications, and transparent trustworthiness. By choosing the MAZ brake drum, industrial decision-makers and engineers invest in a solution that not only meets current operational needs but also anticipates future challenges, ensuring long-term reliability and a competitive edge.

References:

- American Society for Testing and Materials (ASTM) Standards. "ASTM A48 / A48M, Standard Specification for Gray Iron Castings."

- International Organization for Standardization (ISO). "ISO 9001:2015, Quality management systems – Requirements."

- American National Standards Institute (ANSI). "ANSI B11.1, Safety Requirements for the Construction, Care, and Use of Power Presses."

- Society of Automotive Engineers (SAE) International. "SAE J431, Automotive Gray Iron Castings."

- International Organization for Standardization (ISO). "ISO 1940-1:2003, Mechanical vibration – Balance quality requirements for rotors in a constant (rigid) state – Part 1: Specification and verification of balance tolerances."

This is the last article

-

Durable Brake Drum MAZ for Heavy Duty Trucks | High Performance

NewsAug.26,2025

-

FUWA: Premium Quality, Reliable Performance & Innovative Solutions

NewsAug.25,2025

-

Liza Brake Drum: Superior Quality & Performance for Safe Driving

NewsAug.24,2025

-

Iveco Brake Drum | Premium OE Quality for Daily & Eurocargo

NewsAug.22,2025

-

Your Brake Drum Man: Quality & Performance Parts

NewsAug.21,2025

-

Explore Japan: Ultimate Travel Guide & Authentic Experiences

NewsAug.19,2025